The Engineer’s Manual

of Construction Site

Planning

The Engineer’s Manual

of Construction Site

Planning

Jüri Sutt

Professor of Construction Economics and Management

Tallinn University of Technology

Irene Lill

Professor and Head of Department of Building Production

Tallinn University of Technology

Olev Müürsepp

Associated Professor

Tallinn University of Technology

This edition first published 2013

© 2013 John Wiley & Sons, Ltd

Registered Office

John Wiley & Sons, Ltd, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ,

United Kingdom

Editorial Offices

9600 Garsington Road, Oxford, OX4 2DQ, United Kingdom.

The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, United Kingdom.

For details of our global editorial offices, for customer services and for information about how

to apply for permission to reuse the copyright material in this book please see our website at

www.wiley.com/wiley-blackwell.

The right of the author to be identified as the author of this work has been asserted in

accordance with the UK Copyright, Designs and Patents Act 1988.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording

or otherwise, except as permitted by the UK Copyright, Designs and Patents Act 1988,

without the prior permission of the publisher.

Designations used by companies to distinguish their products are often claimed as trademarks.

All brand names and product names used in this book are trade names, service marks,

trademarks or registered trademarks of their respective owners. The publisher is not

associated with any product or vendor mentioned in this book.

Limit of Liability/Disclaimer of Warranty: While the publisher and author(s) have used their

best efforts in preparing this book, they make no representations or warranties with respect to

the accuracy or completeness of the contents of this book and specifically disclaim any implied

warranties of merchantability or fitness for a particular purpose. It is sold on the understanding

that the publisher is not engaged in rendering professional services and neither the publisher

nor the author shall be liable for damages arising herefrom. If professional advice or other

expert assistance is required, the services of a competent professional should be sought.

Library of Congress Cataloging-in-Publication Data

Sutt, Jüri.

The engineer’s manual of construction site planning / Jüri Sutt, Irene Lill, Olev Müürsepp.

pages cm

Includes index.

ISBN 978-1-118-55609-2 (pbk.)

1. Building sites–Planning–Handbooks, manuals, etc. 2. Building–Superintendence–

Handbooks, manuals, etc. 3. Civil engineering–Handbooks, manuals, etc. I. Lill, Irene.

II. Müürsepp, Olev, 1936– III. Title. IV. Title: Manual of construction site planning.

TH375.S88 2013

692′.1–dc23

2013002862

A catalogue record for this book is available from the British Library.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in

print may not be available in electronic books.

Cover image: © iStockphoto/urbanglimpses

Cover design by Meaden Creative

Set in 11/14pt Palatino by SPi Publisher Services, Pondicherry, India

1 2013

v

Contents

List of Figures viii

List of Tables x

About the Authors xi

Preface xiii

Introduction 1

Chapter 1: Initial data 5

1.1 The project (design) documentation 6

1.2 The bill of quantities and the bill of activities 7

1.3 Job descriptions and specifications 7

1.4 The contract conditions set out in the bidding

invitation documents 8

1.5 The report of the construction site inspection 8

Chapter 2: Outline of site management

planning in the bidding stage 15

2.1 The goal 16

2.2 The explanatory note 16

2.3 Construction site layout 19

2.4 The construction time schedule 21

2.5 Cost estimation of temporary works

and construction site set-up 23

Chapter 3: Outline of site management

after contract signature 28

3.1 The goal 29

3.2 Initial data 29

3.3 Construction site layout 30

3.4 Construction scheduling 35

3.5 Calculation of site work quantities and

estimate of costs 46

vi Contents

Chapter 4: Suggestions for choosing

constructioncranes 51

4.1 General 52

4.2 Selection and positioning of tower cranes 53

4.3 Selection and impact areas of mobile cranes 77

4.4 Cranes working near overhead power lines 91

4.5 Hoist danger area 94

4.6 Operating cranes near buildings in use 95

4.7 Restrictions on crane work 97

4.8 Working in the danger area 98

Chapter 5: Suggestions for calculating

resource requirements 99

5.1 Construction site temporary roads 100

5.2 Construction site storage 105

5.3 Temporary buildings 111

5.4 Temporary water supply 115

5.5 Temporary heating supply 116

5.6 Temporary power supply 121

5.7 Construction site lighting 126

5.8 Construction site transport 127

5.9 Load take up devices 130

5.10 Construction site fencing 135

Chapter 6: On-site safety requirements 137

6.1 General basics and responsibilities 138

6.2 The duties of building contractors 141

6.3 The obligations and rights of the labourer 144

6.4 Ensuring safety on the construction site 146

Chapter 7: Requirements for work equipment 155

7.1 General requirements 156

7.2 Mobile work equipment 158

7.3 Lifting devices 160

7.4 Dangers from energy 161

7.5 The usage of work equipment 163

Contents vii

7.6 Usage of work equipment for temporary

work at height 164

7.7 Work with flammable and explosive materials 168

Chapter 8: Work healthcare 169

8.1 Allowable physical effort 170

8.2 The usage of personal protective equipment 170

8.3 Welfare facilities and first-aid 171

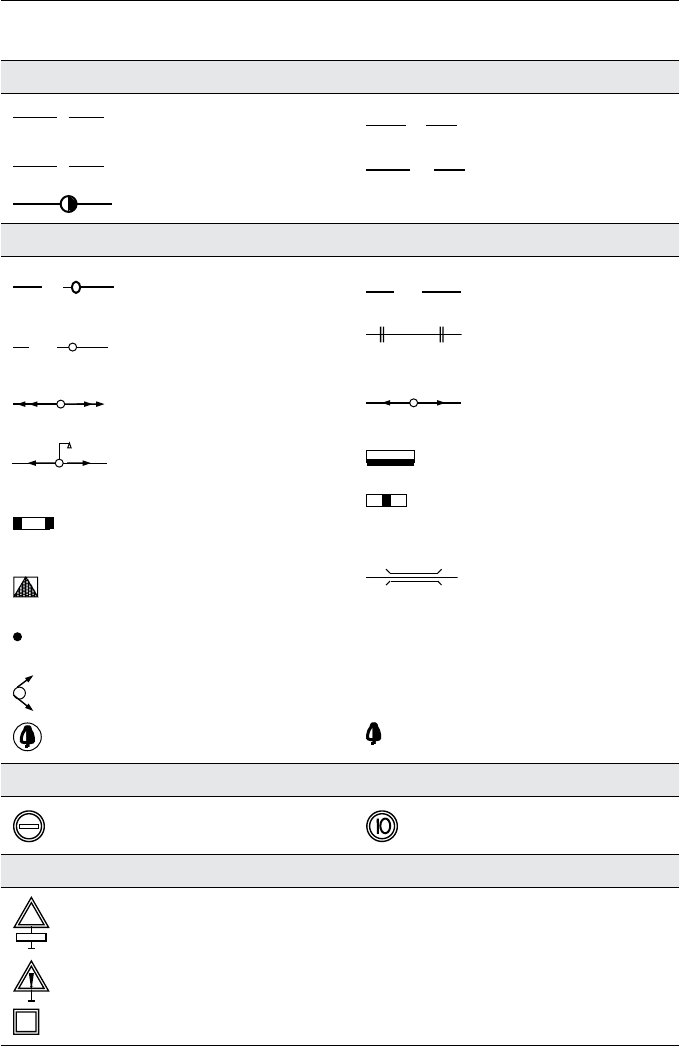

Appendix: Construction site layout symbols 173

Bibliography 177

Index 178

viii

List of Figures

Figure2.1 Site layout in the bidding stage 20

Figure2.2 An example of a time schedule in the

bidding stage 22

Figure3.1 An example of construction site layout for

the frame erection stage 34

Figure3.2 Network model for construction 37

Figure4.1 Drafting geometrical parameters for

a tower crane 54

Figure4.2 Tower crane Liebherr 550 EC-H40 Litronic

radius and capacity chart 57

Figure4.3 Cross-linking the tower crane to the axes

of the building under construction 59

Figure4.4 Positioning the crane track on the edge

of an unsupported recess slope 60

Figure4.5 Longitudinal linking of the tower crane

with building under construction 63

Figure4.6 Danger areas around the building 66

Figure4.7 Boundaries of the danger area 66

Figure4.8 The tower crane impact areas 69

Figure4.9 Danger areas above the building 70

Figure4.10 Simultaneous operation of two cranes

on the same rail track 73

Figure4.11 Simultaneous operation of two cranes

positioned on opposite sides of the building 75

Figure4.12 Simultaneous work of two cranes positioned

between two buildings under construction 76

Figure4.13 Calculating mobile crane minimum

boom length 78

Figure4.14 Assembling at an angle 81

List of Figures ix

Figure4.15 Example of determining the assembly

parameters based on lifting capacity chart

for the RDK 25 crawler crane 85

Figure4.16 Example of determining the assembly

parameters for the Liebherr LTM 1030

mobile crane 86

Figure4.17 Positioning of mobile cranes at the edge of

unsupported recess slopes 88

Figure4.18 The minimal acceptable horizontal

distance s

5

from the bottom edge of a recess

with an unsupported slope to the nearest

outrigger of the crane (m) 89

Figure4.19 Danger area of mobile crane equipped

with boom fall prevention device 90

Figure4.20 Surveillance and danger areas of aerial

power lines 91

Figure4.21 Extent of the surveillance and danger area

of the electrical overhead power line 92

Figure4.22 Safe positioning of mobile crane close

to overhead power lines 94

Figure4.23 Conditions of operation for tower crane

near a building in service 96

Figure5.1 Various kinds of construction site road 104

Figure5.2 Double- and quadruple-branched slings 132

x

List of Tables

Table2.1 Example form of construction site cost

estimate during the bidding stage 26

Table3.1 Example of construction work classication 44

Table3.2 List of costs for temporary and building site

management works 47

Table4.1 Assembly parameters of precast elements

andlifting parameters of tower crane 56

Table4.2 Assembly parameters of precast elements 82

Table4.3 Lifting parameters of chosen mobile cranes

compared to the assembly parameters

of precast elements 84

Table5.1 Average space required for storage of

construction materials 110

Table5.2 Recommendations for surface lighting

in construction 125

xi

About the Authors

Jüri Sutt has nearly 50 years of experience in construction

management as a practicing manager, researcher, consultant

and lecturer which has included designing the construction

technology for large mines in Siberia, a gas trunk pipeline

in Libya and managing a construction firm. In 1965, he

pioneered the use of IT in construction management research

in Estonia. Between 1965 and 1980, J. Sutt was a member of

several USSR scientific councils in the field of construction

management, and from 1965 to 1978, he was the head of the

Construction Management Department of Estonia’s State

Building Research Institute which developed scheduling and

cost estimating IT systems that were widely used in the

Soviet Union.

He has been an adviser to four ministers responsible for building

during Estonia’s transition to a free market economy and led

working groups elaborating construction market regulations in

the 1990s. In addition, he has provided consultancy services for

clients’ projects and contract management and has gained

expertise in contract disputes in the last 15 years.

In 1960, J. Sutt qualified as a construction engineer. He was

awarded the Candidate of Science degree in 1968 (equivalent

to a PhD), and, in 1989, the Doctor of Science (habil.) in math-

ematical methods and IT in economics. The principal outcome

of his research has been the methodology of IT simulating

production – economic activities of construction firms enabling

experimentation with different economic mechanisms and

management strategies in construction enterprises.

Since 1989, he has been Professor of Construction Economics

and Management at the Tallinn University of Technology.

Irene Lill graduated from Tallinn University of Technology as

civil engineer, and defended her degrees in the same univer-

sity (PhD and MSc in Economics). She has over 20 years of

academic experience in the university. She has been working

in research closely with Jüri Sutt, initially as professor and

student and as good colleagues today. Since 2005, she has been

professor and head of department of Building Production in

Tallinn University of Technology.

Olev Müürsepp graduated from Tallinn University of Tech-

nology as a civil engineer. He has nearly ten years of experience

working as a site and project manager in a construction enter-

prise and three years in a large design firm as a consulting

engineer in the field of design of technology and organisation

of construction. For 10 years, he has worked in the Construction

Management Department of Estonia’s State Building Research

Institute as a researcher in the field of modelling technologi-

cal and organisational decisions in civil engineering. In 1987,

he defended his PhD in this specialist area of construction

engineering. Since1991, he has worked as associated professor

in Tallinn University of Technology.

xii About the Authors

xiii

Preface

This handbook deals with the problems of engineering prepa-

ration for building in a construction company, both during the

bidding phase and after a contract has been concluded.

The handbook’s recommendations can also be used in the

design phase, when the building contractor is not yet

selected. In this case, it has the aim of assuring the con-

structability of the designed building and of calculating a

control estimate for the owner in order that bids can be

weighted and contractors’ potential duration of construction

can be evaluated. In the design stage, the methods used are

similar to those of the contractor in the bidding phase, when

aggregated norms are used.

The key problems consist of identifying the composition of

complex project organisation and level of detail of the initial

data, the inspection of the construction site, compiling the

construction site layout and the construction schedule, and

the cost estimate of construction site expenses. Suggestions

for calculating the resource allocation are presented: for

the selection of cranes and lifting devices, the planning

of temporary buildings and roads, and for technological

networks, fire safety, fencing and lighting. On-site safety

precautions in planning of the construction site management

are discussed.

The owner’s construction costs are determined through

cooperation between the owner and the designer/consultant,

according to preliminary design task as set out by the

xiv Preface

ownerand the designer’s technical and aesthetic competence.

Thestructural designer must ensure the building’s strength,

stability, compliance with environmental criteria, etc. These

costs are also affected by the detailed plan requirements

validated by the local authorities. Another concern is

thatnot enough attention is paid to construction management

and building technology during the design of the construc-

tion contract conditions, and their subsequent negotiation.

This, however, impacts the duration of construction, and

based on this the contractor will be able to make the lowest

price offer without reducing the quality of constructing.

Often ignored is the fact that temporary works and

tempo rary facilities on the building site form up to 12% of

total costs, depending on the type of the building, site

conditions, seasonality and the building owner’s stipulations

on duration.

This can be explained by the fact that construction site

management and temporary facilities costs are not reflected

in the final physical form of the building and will therefore

remain unnoticed unless specially outlined by the consultant.

Construction site management is reflected in the economic

result of the owner’s investment in the construction project,

especially for business projects. The quicker the construction is

completed, the sooner it becomes profitable.

For example, for a building that costs €100 million, with an

annual profit rate of 10%, shortening the duration of con-

struction would provide an additional monthly profit of

approximately €0.8 million, and furthermore, it would enable

the saving of about €0.5 million on the construction loan inter-

est payments. Nevertheless, it should not be forgotten that for

the contractor, this may entail organising the work into several

shifts, bearing in mind winter conditions, etc., and the resulting

additional costs will need to be compensated.

Preface xv

For this reason, the importance of the preparatory engineering

work, called construction site management design, cannot be

underestimated. Overall, it is divided into three phases:

The project’s main designer orders the construction site

management project from a specialised consultancy com-

pany. The result forms the basis of the owner’s financial

plans (loan agreements) and the conditions of the contracts

with designers and builders.

The contractor prepares the construction site management

project for calculation of bidding price and construction

deadline.

The firm that wins the competitive bidding process prepares

the construction site management project consisting of the

site plan and time schedule, at the same time calculating the

cost price and compiling working drawings.

This handbook describes the specifics of the last two stages,

bearing in mind that in the first stage, that is the design phase,

the preparation of the construction site management project is

similar to the contractors planning of site management in the

bidding phase. However, it may be less detailed because the

construction company is as yet unknown. However, how can

the owner prepare a financial plan and predict the temporal

parameters of the loan agreements without calculating the

duration of construction? Preparing a time schedule requires a

scheme plan of the site and temporary works. Preparing a

construction site management project in the design phase cer-

tainly requires involvement of a specialised consultant or an

impartial contractor.

This handbook is meant for planners of construction site

management, construction engineers and construction site

xvi Preface

quantity surveyors, but also for students who specialise in

civil engineering and construction.

The authors are grateful to J. R. Illingworth, D. J. Ferry,

P.S.Brandon, H. Bauer, R. Salokangas, L. Dikman, F. Harris

and R. McCaffer who have analysed different aspects of con-

struction site management and inspired the authors of this

handbook to approach the construction site problems from a

different perspective – as a set of simultaneous problems.

In compiling the book, Jyri Orlov (MERKO AS), Taimo Kikkas

and Enn Siim (Skanska EMV AS) helped the authors by pro-

viding useful hints and suggestions, and the authors are very

thankful to them.

If there are discrepancies between recommendations given in

the present handbook and prescriptions given in local laws,

codes, instructions or standards, local regulations must be

followed.

His co-authors - Irene Lill and Olev Müürsepp - and

hispublishers were saddened to hear of the death of

JüriSutt, whopassed away on April 20th 2013.

The Engineer’s Manual of Construction Site Planning, First Edition. Jüri Sutt, Irene Lill

and Olev Müürsepp.

© 2013 John Wiley & Sons, Ltd. Published 2013 by John Wiley & Sons, Ltd.

1

Introduction

The aim of construction site management planning is to find

solutions to erect buildings in the cheapest, fastest and safest

way possible, based on construction sketches and layouts,

valid design and building standards, and on the owner’s

wishes concerning construction time and demands for the

quality of the construction. Planning of site management is

based on knowledge of building technology and different

methods of the time scheduling of construction work.

To fulfil this goal, one must prepare:

the budget of the construction expenses;

the time schedule of construction works;

the construction site layout(s);

the cost estimate for the set-up of temporary buildings and

site management;

the list of risks.

In the methodological sense, this task entails the planning

of alternative solutions from the viewpoints of building

technology and site management, the assessment of those

2 The Engineer’s Manual of Construction Site Planning

solutions on the basis of the chosen criteria and, finally,

selection between them.

In making the selection, the following evaluation criteria can

be applied:

the proportion (%) of the cost of the temporary buildings in

relation to the general cost of the building complex, which in

construction varies to a great extent (1.5–12%);

duration of the construction period;

the bill of quantities for temporary buildings, including their

proportion within the overall cost of temporary works;

the quantity (length, area) of temporary construction and

their cost by type of construction (temporary roads, build-

ings, utility networks, etc.);

the unit cost of temporary buildings and facilities per €1 million

of construction cost, or per hectare of construction territory

(used mainly during the construction pre- planning stage);

total labour consumption of erecting temporary buildings in

man-days (for construction preparation period separately),

and unit quantity of work per unit area of construction, or

per total cost of construction, or another parameter.

Distinguishing building technology and building management

is by convention. By the planning of building technology we

mean:

the description of construction process in space (the plan

and section of the construction site and/or work front);

Introduction 3

the description of the construction process and resource

allocation in time (line charts or time-space charts);

the work quality requirements;

the allowed tolerances;

the safety requirements, taking into the account working

methods and tools.

By construction management we mean making separate works

compatible with each other in order to erect a building as a

whole, that is above all, the correlation between various

construction works and processes, the conditions of preparing

and handing over the job site, separate works and completed

construction stages.

Keeping in mind the purposeful differences of each con-

struction project at the development stage, we must separate

the planning of building management into two different

phases:

bidding calculations; and

after winning the bidding competition, preparation of a

contract.

The solutions presented will be considerably more precisely

detailed in the second phase because the actual field of

production in a construction company is being dealt with – the

planning of the more or less complex processes of building.

During the first phase of design, the issues and problems that

have to be solved in the second phase should be identified.

4 The Engineer’s Manual of Construction Site Planning

This handbook deals with the methods of planning the building

site management that are largely common in regular construc-

tion, above all in erecting buildings. It does not concern work

management for special structures (line structures, water

structures, power plant structures and chemical industry

plants, etc.). Neither does it deal with the compilation of

technological charts (instructions) for each individual building

process, nor will it present a catalogue for technological charts.

The list of all the actions and the documents compiled as a

result of the actions described in the guide is long, and this

means that not all of these procedures may need to be per-

formed or their results presented in the same thoroughness or

formality in every project. Thus, the guide serves as a reminder,

referring to issues where the construction company has to take

a decision when it wants to take part in any particular project.

The Engineer’s Manual of Construction Site Planning, First Edition. Jüri Sutt, Irene Lill

and Olev Müürsepp.

© 2013 John Wiley & Sons, Ltd. Published 2013 by John Wiley & Sons, Ltd.

5

Initial data

Chapter 1

Chapter outline

1.1 The project (design) documentation

1.2 The bill of quantities and the bill of activities

1.3 Job descriptions and specifications

1.4 The contract conditions set out in the bidding invitation

documents

1.5 The report of the construction site inspection

6 The Engineer’s Manual of Construction Site Planning

1.1 The project (design) documentation

For preparation of site management solutions and decision

making, the following documents are necessary:

the layout of the plot of land (the construction site situation

plan), on which buildings under construction, existing

buildings (including those due to be demolished) and utility

networks, roads, paths, courts and geodetic data (including

contours) are indicated;

the plans and sections of buildings under construction;

the head-note stating the general description of the project,

the data of the architectural solution and the geological and

hydrogeological conditions of the site;

the list, location and capacity of existing utility networks,

and those to be set up and demolished;

the results of the project site survey, for example the availa-

bility and location of quarries, sources for supplying the

construction site with electricity and water, the throughput

of roads and bridges and various other documents.

The completeness of these data depends largely on the level to

which the client/owner has resolved the tasks relating to the

project survey and design phases of construction. In the call for

tenders, it is advisable for the client to present the basic design,

rather than only a building scheme design (brief), and other

data in relatively limited format.

Here and later, we presume that the design of a construction

investment project is divided into the following design stages:

Initial data 7

scheme design (brief), the basis of feasibility studies;

preliminary design, the basis for permission to build from

local authorities;

basic design, the basis for construction works;

working drawings – the engineering solution for complicated

assemblies, which can include technological instructions.

1.2 The bill of quantities and the bill of activities

The bill of quantities should be an integral part of basic design

and included in the bidding invitation documents (if the owner

has ordered a bill in the contract to design). If a bill of quanti-

ties at the level of unit price is absent, then a bill by structural

units and engineering facilities, with corresponding unit

measures and physical capacities, must be used (part of the

preliminary project). This list is called the bill of activities.

The contents of either the bill of activities or bill of quantities

serve as the basis for assembly of the time schedule. If these bills

are absent from the bidding invitation documents, they will be

drafted by the construction company, ascertaining beforehand

whether the client has any specific requirements for particular

measurement instruction for the works, or for the classification

of the construction costs presented in the bidding.

1.3 Job descriptions and specifications

Specifications are part of the bidding invitation documents,

which need to be examined in order to determine their

completeness; likewise, the client’s particular requirements

8 The Engineer’s Manual of Construction Site Planning

relating to building material, machinery or the quality of

building works, which may necessitate special building tech-

nology, and equally the client’s specific requirements concerning

the storage or preparation of materials/products.

1.4 The contract conditions set out in the bidding

invitation documents

Contract conditions might influence site expenses (deadline,

duration of construction, design and building management,

construction stages, restrictions on selection of subcontractors,

etc.) and should be specified by the client in the bidding

invitation documents.

1.5 The report of the construction site inspection

Before making the plan of the construction works and the

calculations for bidding, one must become acquainted with

the contract conditions, the project documentation, the bill of

quantities and the bill of activities and specifications and

undertake a site visit. The form of the land, its geological and

hydrogeological conditions and the disposition of existing

structures on the plot and in the vicinity might significantly

influence the selection of building technology (including type,

quantity and location of machinery on the site), the extent of

construction costs (direct, as well as general, site-dependant

costs), the duration of the construction and the probable risks.

Arepresentative of the client should also be present at the con-

struction site inspection to answer any questions that may arise.

A report of the construction site inspection must be drafted,

signed and dated. Photographs of the construction site will

be added if necessary. Any questions in the report of the

Initial data 9

construction site inspection that require written answers

should be included at this point. This handbook recommends

using the following questionnaire. The bidder is free to add

to the questionnaire depending on the project and on the

conditions of the contract.

1) Access roads

r Are there any restrictions arising from the width, height

or load-bearing capacity of access roads, bridges or

overpasses?

r Could construction transport or machinery damage or

litter the existing roads resulting in the need to pay

compensation to the client, the local government or

anythird party?

r Is it necessary to access private premises in order to get to

the construction site, and if so what would the costs be?

2) The conditions of construction site occupation

r Is it possible to use:

the existing roads or the underlay of designed roads as

temporary roads?

existing sites to store materials and as set-aside ground

reserves?

r What obstacles need to be dismantled (moved):

above ground (piping, wiring, trees, etc.)?

on the ground (piping, protected surfaces, etc.)?

10 The Engineer’s Manual of Construction Site Planning

underground (drainage, piping, cabling, old

foundations)?

existing buildings and other structures?

r What is the situation with regard to:

trees (do they need preservation and protection, do

they obstruct the work of construction machinery, is it

necessary to measure their height)?

objects (of antiquity, architecture, nature) under

preservation and are there any resulting restrictions?

bodies of water (is there a possibility of altering the

water levels, or is there a need for bridging)?

r What else needs to be done in the erection of tem porary

buildings and structures and construction site setup?

3) The boundaries of the construction site and adjacent areas

r What kind of buildings and trees surround the construction

site and the property? Measure their height to ensure

they will not obstruct the working radius of the crane. Do

they need protection, and if so, how?

r Measure the distance of the building under construction

from the construction site boundary or the existing build-

ings. Is it enough for the installation of lifting devices,

movement of machinery and erection of scaffolding? Is it

necessary to make any special arrangements (e.g. partial

or complete closure of a road) in order to use the building

technology planned?

Initial data 11

r Ensuring the safety of outside staff or visitors:

Is it necessary to ensure passage on site for vehicles

and/or people not associated with construction? Does

this require special measures, for example construction

of temporarily covered walkway in the danger area

(crane, hoist and/or scaffolding)?

Is it necessary to build a temporary pavement and

temporarily covered walkway on the fencing of the

construction site?

Are there any kindergartens, schools, playgrounds in

the adjacent area? What measures are necessary to

ensure the safety of children? Does this require special

measures for the construction work?

r Are there any bodies of water with altering water

levels that might affect the construction works (e.g.

needfor special dewatering measures in the area of

con struction excavation, strengthening of temporary

roads,etc.)?

r Proximity of an airport to the construction site: might this

restrict the height of the cranes, etc.?

r Presence of adjacent utility networks, for example electric

and communication cables, piping: might they cause

additional restrictions and risks?

r Problems arising from environmental protection: might

they cause additional restrictions and risks?

The need to inform the public (in the vicinity); if yes, at

what time?

12 The Engineer’s Manual of Construction Site Planning

4) Noise

The restrictions on the level of noise and its duration must be

ascertained from local government. This is particularly impor-

tant if there are schools, children’s institutions or hospitals

close by. There might be special restrictions to work during the

evening and night.

5) Facilities for the supply of water and electricity for

construction

Application for technical permissions for the supply of water

and electricity for construction must be completed and

submitted to the appropriate boards. Despite the allocation

and connection of water and electricity for the erection of (per-

manent) buildings being agreed in the project documentation,

the amount of water and electricity used during construction

could be greater.

6) Soil, geological and hydrogeological conditions

Even if this data is stated in the building design documentation,

the contract applicant should still inspect the construction site.

When conducting an inspection during a dry period, one must

not forget the possibility of change in conditions during heavy

rain or in winter.

One can draw conclusions by observing the flora and also by

questioning residents. Whether there is indication of soil con-

tamination must also be ascertained.

7) Restrictions on working hours

When carrying out construction work in foreign countries, it is

important to know the local restrictions on the length of the

Initial data 13

working week, the number of working hours per day and

overtime hours. In addition, the dates of public holidays and

possible collective vacations have to be determined.

8) Local weather conditions

Determining the weather conditions is vital in order to esti-

mate possible time risks. Weather information is available from

the local meteorological service and local residents.

9) Regulations set by the local authorities on building and

recycling of materials

These activities involve:

r Determining detailed overall area plan and servitudes,

which can influence the building site layout and / or con-

struction time schedule;

r Competence-, technical-, financial- or other requirements

to contractor according to law of local authorities;

r Peculiarities of registering the building according to local

authorities;

r Regulations of using local raw construction materials;

r Local recycling regulations.

In case of building in foreign countries, it is compulsory

beforestarting planning the building site to get familiar with

the building law of the country; good construction practice;

trade and crafts unions’ regulations, etc., as these can influ-

ence the on site safety conditions and labour usage, marking

the site, guard fencing and responsibility issues.

14 The Engineer’s Manual of Construction Site Planning

All the described activities of construction site inspection have

a goal to minimise the cost of construction, its duration and

the risk level as early as possible using methodology of

engineering preparation of construction.

The Engineer’s Manual of Construction Site Planning, First Edition. Jüri Sutt, Irene Lill

and Olev Müürsepp.

© 2013 John Wiley & Sons, Ltd. Published 2013 by John Wiley & Sons, Ltd.

15

Outline of site

management planning

inthe bidding stage

Chapter 2

Chapter outline

2.1 The goal

2.2 The explanatory note

2.3 Construction site layout

2.4 The construction time schedule

2.5 Cost estimation of temporary works and construction site

set-up

16 The Engineer’s Manual of Construction Site Planning

2.1 The goal

The goal of construction site management planning in the bidding

stage is to identify problems that may occur with construction

from the point of view of the knowledge and resources of the

construction company, and to estimate construction costs relating

to the building site from the point of view of the requirements set

out in the bidding invitation documents. The outline of building

management in this stage does not represent a prescription of

work, but rather the documentation necessary for bid prepara-

tion (cost and duration) or a reason for withdrawal.

The outline of site management in the bidding stage consists of

the following documents:

explanatory note;

site layout sketch;

general time schedule of construction works by neighbour-

ing subcontractors;

approximate estimate of site costs;

list of site management issues requiring change or elabora-

tion prior to conclusion of contract.

2.2 The explanatory note

The explanatory note briefly summarises the site management

plans that will be presented to the bidding panel along with other

documents mentioned earlier. The explanatory note contains:

Outline of site management planning inthe bidding stage 17

1) the list of major buildings and facilities in the building

complex;

2) a description of the relationship between the owner/client

or the owner and the client, if they are not being represented

as one person or institution;

3) the schemes of procurement (missing parts of basic design

or working drawings) and price mechanism (fixed lump

sum, fixed lump sum with added bill of quantities, target

price with cost reimbursement, etc.);

4) recommendations on the selection of subcontractors;

5) the total costs of temporary works, the same as a percentage

of total construction costs, and the deviation from the

average compared to similar projects;

6) duration of construction, including:

r duration desired by the owner;

r rational duration concluded from the time schedule;

r contractor’s time in reserve if he thinks that work can be

completed more quickly;

r list and duration of actions to be performed in winter;

r need for shift work (what kind of works, percentage of

the total), the resulting increase in direct costs;

r possibility, and rationale for, additional shortening of

construction duration.

18 The Engineer’s Manual of Construction Site Planning

7) Problems related to:

r materials and products;

r labour;

r construction machinery;

r subcontractors.

8) Other risks, for example:

r inadequacy of geological explorations;

r uncertainty about the client’s ability to pay;

r quality of the presented drawings of buildings and

facilities, including their co-ordination;

r any contradictions between the drawings and the bill of

quantities;

r instability of the electrical supply, possible antiquity

surprises, etc.

9) Issues that might need adjustment after the contract has

been signed. These could be:

r technical conditions and contracts of temporary water

supply, sewerage and electrical supply;

r redesign of foundations and frameworks to identify any

possible financial savings;

r search for a buyer for any spare soil or recyclable mater-

ials emerging during demolition, etc.

Outline of site management planning inthe bidding stage 19

2.3 Construction site layout

In this stage of contract management, the construction site

layout is drafted as a sketch. The basis for this can be the plot

layout or the location plan of site structures, on which the

objects necessary for decision making from the site manage-

ment standpoint may be drawn in freehand:

existing buildings and structures (buildings and utility

networks) on the site, the need to relocate or demolish same

during the site setup, their availability for use during

construction works;

crane movement areas and danger zones;

access roads with remarks concerning their state of order or

the location of any planned new access roads;

temporary roads on the site;

the storage locations of materials and structures;

in the case of a narrowly confined construction site, storage

possibilities outside the site should be laid down on the

situation plan of the construction;

temporary buildings (offices and rooms for workers);

temporary facilities on the site. The possible conditions for

connecting to the electrical network, and connecting water

and sewerage to existing pipe-work;

excavated soil and storage of set-aside earth on the construc-

tion site;

20 The Engineer’s Manual of Construction Site Planning

possibilities for waste storage on the construction site;

the fencing of the construction site.

Since the construction site layout is based on the general situa-

tion layout of the project, and the solutions presented are

impossible to elaborate in detail in this stage, the layout is

compiled at a scale of 1:1000, 1:2000 or 1:5000.

If required, a vertical section of the building should be added

to the layout to evaluate crane measurements. An example of a

construction site layout in the bidding stage is given in Figure2.1.

When drafting the construction site layout, the following

should be observed:

coherency with other parts of the building outline (design

documentation);

Shelters

Office

Stockrooms

Pents

Precast

concrete

elements

Formwork

Rein-

forcement

Waste

R = 36 m

R = 36 m

Set aside

growing soil

Set

aside

ground

Existing road

Existing road

Figure 2.1: Site layout in the bidding stage.

Outline of site management planning inthe bidding stage 21

accordance of construction works duration (the time

schedule) with the chosen number of cranes and technologi-

cal measures as planned on the site layout;

the duration of construction pertinent to the time schedule

(the number of cranes, etc. is dependent on this);

the main building technology chosen;

job safety requirements;

fire safety requirements;

environmental safety requirements;

the goal for the lowest costs possible. This can be achieved

by the help of:

r the use of the buildings present on the construction site

and those subject to demolition as temporary buildings

while this does not interfere with the construction

work,

r the combining of temporary and permanent roads and

sites,

r the management of construction works according to

asrational a scheme as possible, ruling out unreason-

able accumulation of multiple works in a short time

period, etc.

2.4 The construction time schedule

The following should be indicated separately on the construc-

tion time schedule:

Figure 2.2: An example of a time schedule in the bidding stage.

Outline of site management planning inthe bidding stage 23

the works performed by the owner;

the design works;

the construction site set-up works;

the building construction works listed by main structural

elements, indicating separately the works performed by the

contractor’s own forces, the works that require erection and

lifting machinery, and the works that require scaffolding,

utility network construction works outside the construction

site.

For every instance of work required, the duration in months

(weeks), the number of workers and the number of shifts per

day are given. An example of a time schedule used in the

bidding stage is displayed in Figure2.2.

2.5 Cost estimation of temporary works and

construction site set-up

In this stage of cost estimation the following nomenclature of

costs should be adopted. For every cost type, a corresponding

normative unit measure is added, for example:

costs for cranes and lifting machinery €/day;

costs for construction site fencing €/m;

costs for temporary roads and storage sites €/m

2

;

costs for temporary water supply pipelines €/m;

24 The Engineer’s Manual of Construction Site Planning

costs for temporary sewerage facilities €/m, €/day;

costs for temporary electrical power

distribution €/m;

costs for temporary buildings €/m

2

× day;

costs for construction site lighting €/kW;

costs for fire safety precautions €/m

2

;

costs for winter heating €/m

3

× day;

costs for concrete maintenance in winter €/m

3

× day;

costs for dewatering €/day;

costs for street and construction site upkeep €/m

2

;

costs for managing work on site €/man-day;

other costs €/man-day.

When estimating costs, the company’s own overall normatives

are used with measurement units for each item. In small com-

panies with no normatives, experiential appraisals are used.

The duration of the work, or of the use of service (crane work,

heating of buildings, heating of concrete, dewatering), in days

is gathered from the construction time schedule (Figure2.2).

Labour inputs in man-days are calculated on the basis of a

graph of labour allocation according to the time schedule and

the corresponding duration of work.

The areas (m

2

) requiring snow sweeping and street upkeep, the

length of construction site fencing and utility networks (m) is

Outline of site management planning inthe bidding stage 25

measured on the site layout (Figure2.1). The estimated heating

cost for buildings is calculated from the cubage of the building

and length of the cold period (m

3

× number of days); costs

forclearing snow on the other hand are calculated from the

area oftemporary roads and sites and length of the winter

(m

2

× number of days).

The cost norms (€ or physical units) for further use of necessary

equipment, or the adjustment of existing norms, are calculated

in the second stage of site management planning, that is on the

basis of detailed cost estimates (or post-factum cost estimation)

compiled after signing the contract.

This requires that construction site cost estimates are archived

in the construction company and that the codes and units of

cost item measurement are compiled consistently.

In addition to applying the construction site (temporary works)

cost planning method in the bidding stage (as described), the

construction company, whose works (buildings) and range are

rather similar, can calculate construction site costs using even

more widely aggregated norms.

For example, these norms could be the aforementioned 15-point

summary divided either by:

the cubage of the building €/m

3

;

the construction site area €/m

2

;

the duration of construction in days €/day; or

the cost of construction in direct expenses €/€.

An example of construction site cost estimation during the

bidding stage is presented in Table2.1. This form also shows

26 The Engineer’s Manual of Construction Site Planning

Table 2.1: Example form of construction site cost estimate during the bidding stage

………………………………………………………………………………………..……........

(Name of the project)

Construction Site Cost Estimation

Cubage of buildings…………………………………………... m

3

Construction site area……………………………………….... m

2

Construction duration ………….…………………………... days

Cost of construction in direct expenses………………….... €

Code Type of cost Measurement

unit

Quantity Price Cost

1 Cranes and other lifting devices Day/shift

2 Construction site fencing m

3 Temporary roads and

storagesites

m

2

4 Temporary water supply m, m

3

5 Temporary sewerage m

6 Temporary power supply m, kW

7 Temporary buildings m

2

× day

8 Site lighting kW, m

2

9 Fire safety m

3

10 Heating the building in winter m

3

× day

11 Concrete curing in winter m

3

× day

12 Dewatering days

13 Streets and site upkeep m

2

× day

14 Managing costs on the site man-day

15 Other €

Total €

Costs for building volume €/m

3

Costs for construction site area €/m

2

Costs for duration of construction €/day

Costs for construction direct cost %

Outline of site management planning inthe bidding stage 27

the results of the aforementioned calculations of aggregated

norms (the last four rows in the table).

The aggregated norms of productivity and cost price for

temporary works units required to estimate the expenses

described in this stage can be calculated on the basis of an

analysis of the detailed estimates of such works on analogous

past objects taken after winning the contract, when detailed

unit price norms are used.

The Engineer’s Manual of Construction Site Planning, First Edition. Jüri Sutt, Irene Lill

and Olev Müürsepp.

© 2013 John Wiley & Sons, Ltd. Published 2013 by John Wiley & Sons, Ltd.

28

Outline of site

management after

contractsignature

Chapter 3

Chapter outline

3.1 The goal

3.2 Initial data

3.3 Construction site layout

3.4 Construction scheduling

3.5 Calculation of site work quantities and estimate of costs

Outline of site management after contractsignature 29

3.1 The goal

The aim of site management planning after contract signature

is to give a definite code of practice for the preparation of the

construction site and the execution of construction work on the

site. The aims are similar to those in the bidding stage, except

that the construction site layout, the construction works time

schedule and the estimate of costs are compiled in greater

detail (see Table2.1). The site management outline consists of

the following documents:

construction site layout(s);

the technological model of construction, either as a network

chart or, in the case of flow construction, a time-space chart

(cyclogram);

time schedule of the construction works;

cost estimate of construction site costs;

ordering calculations for resources in accordance with

resource allocation for construction works;

technological instructions for complicated construction

processes (frame erection, piling, etc.).

3.2 Initial data

In addition to the site management outline drafted in the

bidding stage, initial data includes:

contract conditions;

record of the bidding panel meeting;

30 The Engineer’s Manual of Construction Site Planning

technical conditions and utility network integration contracts;

list of subcontractors approved by the client (if contract

conditions prescribe approval);

decision on the technological scheme of the main construc-

tion process (critical path in network chart), including the

number of working shifts;

decision on the selection of a compiler of the working

drawings.

3.3 Construction site layout

For large and complicated construction projects, site layouts are

drafted for the different stages of construction; these could be:

site setup stage;

excavation works;

foundation works;

erection of frame;

mounting heavy and complicated facilities both inside and

outside the building;

roofing works;

finishing works;

external civil engineering utilities networks;

construction of water and sewage cleaning devices.

Outline of site management after contractsignature 31

The layout is drafted at different stages because it is impossible

to reflect schemes showing moving construction machinery

and working teams, the placement of lifting equipment, sites

for material storage, etc. from different phases of construction

on a single ground plan.

On construction site layouts, the following elements are gener-

ally indicated:

original surface contours and benchmarks on buildings and

structures;

drainage of rainfall (scheme);

layout of temporary roads, their widths and structures;

traffic map with necessary traffic signs;

permanent and temporary buildings;

permanent and temporary facilities (utility networks), depth

and height of temporary utility networks, their connections

with permanent networks and locations of wells, cells and

switchgear;

motion schemes of construction machinery used during

erection of frame from precast elements;

location of hoists;

binding of tower crane to the axes of building and position

at off-hour;

vertical scheme of tower crane construction with the overall

dimensions of the building (this can be presented as a sepa-

rate drawing, see Figure4.1);

32 The Engineer’s Manual of Construction Site Planning

location of test load/check weight for the crane;

space for storage of lifting devices and grapple equipment;

location for receipt of concrete and mortar;

storage places for set-aside excavated ground for backfill;

warehouses and storage places for materials and precast

elements by type;

pre-assembly area;

danger areas and their identification;

locations of fire extinguishers and hydrants;

location of switchboards (main switchboard, feed for the

tower crane, etc.);

location of power plant (transformer);

protective fencing;

location of lighting gantries and their heights;

smoking area;

waste containers/storage area;

objects that require protection (high foliage, antiquities,

etc.).

Possible sequence of procedures when drafting the construction

site layout:

Outline of site management after contractsignature 33

choice of possible types of assembly cranes, their number

and allocation, working and danger areas, places for storing

materials and precast elements and also roads in the work-

ing range of cranes. These procedures are interrelated and

must be solved at the same time;

duration of construction in relative time is determined;

resource allocation is determined on the basis of the time

schedule (if the schedule fulfils the deadlines set in the

contract), and includes:

r labour,

r output and voltage of the power supply (kW, V),

r water supply required (l/s),

r most important construction machinery, their main

characteristics and quantity,

r precast elements and materials (average, maximum need

per day, maximum need per shift);

the need for temporary buildings, facilities and technolo-

gical devices and their characteristics are calculated;

construction site boundaries are indicated and a lighting

scheme is drawn up.

Construction site layout is usually set out at a scale of 1:250 or

1:500.

An example of a construction site layout for the erection of a

frame is given in Figure3.1.

Figure 3.1: An example of construction site layout for the frame erection stage.

Outline of site management after contractsignature 35

The symbols used in the construction site layout are in

Appendix 1

3.4 Construction scheduling

Construction scheduling in this stage has the following

purposes:

a detailed description of requirements from the viewpoint of

technology and construction management set at the time of

bidding are taken as a basis, including:

r verification of the bill of quantities and scope of works,

r analysis and adjustment of planned building technology

and site management,

r assessment of the intensity (number of workers engaged)

and duration of works according to the adjusted scope,

r description of works sequence and relationships. In the

case of larger and more complicated construction, advis-

ably in the form of network or time-space chart;

drafting of initial construction time schedule – using this

schedule, the earliest starting and latest completion times of

the subcontractor work presented in the call for tenders are

determined;

selection of building methods in order to secure the greatest

retrenchment in the required construction duration.

This manual stresses that network or time-range charts are

tools for the better elaboration of building technology and

36 The Engineer’s Manual of Construction Site Planning

management, in which every item of work (or stage thereof) is

associated with preceding or subsequent items. If a certain task

can, technologically and from a management point of view, be

initiated before completion of the directly preceding task, then

the necessary readiness extent (in a chronologically calculated

chart on which moment of time is event) of previous work must

be identified in the chart.

The greatest advantage or freedom for the project manager in

further construction time scheduling is available by this type

of flow of work, with the beginning of all tasks in the network

chart coming at the earliest possible time, and the possibility

of completion at the latest, compared to other works. That

isthe best way to make use of slack time and to manipulate

resources in the process of time scheduling. In other words, in

this case the initial schedule of works (the non-chronological

network or time-range chart) is flexible. In addition, the

formation of the technological model of construction as a

network chart will significantly save time for the construction

manager later on, because during further planning, for

example when drafting monthly schedules (during adjust-

ment of the provisional overall plan), the initial chart does not

generally require redrafting as the technological and organi-

sational references initially set out in the network chart will

ensure adherence to the essential sequences and references if

the situation alters.

The second great advantage of the network and time-range

models are the simplicity and speed of computing, which is

important for formulating option solutions as well as adjusting

the schedule of work during construction, and when considering

the deviation of actual work (fill schedules) from the estimates.

The level of detail of the network chart should be chosen to

represent:

Outline of site management after contractsignature 37

works and procedures of the owner that will be completed

after signing the contract;

the drafting of working drawings, if the construction begins

prior to the end of the design work;

construction site setup;

all construction works for erection of buildings and struc-

tures, divided among the company’s own working teams

and all of the desired subcontractors;

previously agreed benchmarks for interim financing.

An example of a network chart reflecting the relations and

conditionality of construction works appears in Figure3.2.

Building

site set up

Earth

works 1

Temporary

buildings and

facilities

Earth works 2

Foundation

works 1

Foundation

works 2

Installation of openings

Roof works

Concrete floors

Construction

of building

envelope 1

Construction of

building envelope 2

Inside

plastering

Inside

painting

Take

over

Exterior finishing works

Tile floors

Internal water supply and sewage works

Interior electrical works (installation of cables)

Internal heating and ventilation works

On-site communication installations

On-site water supply

On-site electric installations

On-site sewage works

Construction of on-site roads Greenery works 2

Greenery works 1

Figure 3.2 Network model for construction.

38 The Engineer’s Manual of Construction Site Planning

For every work included in a network model, the following

data at least must be determined:

name of each item of work (if work is divided into several

parts/cycles, a number is added to the name);

cost of work (from the budget);

number of workers, which is determined by the project man-

ager based on the size of the work front, and the conditions

of the construction site and quantity of building machinery

selected beforehand and their productivity, in order to assure

a smooth servicing for workers;

duration of work, determined on the basis of:

r quantities of works taken from the estimate (evaluated bill

of quantities) and number of workers expertly selected to

do their respective jobs,

r cost of work and the company’s internal working efficiency

(productivity) rate by works and the number of workers, or

r an expert appraisal;

code by worker trade and/or subcontractors;

number of working shifts per day;

technological and organisational restrictions on work, for

example seasonal demands and demand for separate works

to be carried out simultaneously.

The compilation of the initial network model is followed by

calculation of its chronological parameters in comparative

Outline of site management after contractsignature 39

time, that is the calculation is not linked to a calendar in

order to:

check the correlation between construction duration (dura-

tion of the critical path) of the created technological model

and the time limit set by the contract agreement;

determine the calculated early starting and late finishing

times of works and the time float of works;

get a better view of the technological and organisational

relations of works, maximum extents of resource require-

ments (labour, materials, etc.) and their chronological

divisions.

If the presented solutions satisfy the contract conditions, then

the chart is linked to calendar dates giving the dates of the start

of construction and hand over of the completed building as set

out by the contract.

If the critical path turns out to be longer than the duration of

construction set in the contract, then the technological and

organisational solutions set as the basis for the network

chart must be re-evaluated, verifying that the new solutions

are feasible from the point of view of construction site

conditions.

The principal ways to shorten construction duration are:

selecting more efficient plant and machinery or to engage

more workers;

increasing the amount of machinery. This usually requires a

large work front, which can be divided into working sections

and allow various machines to be used simultaneously;

40 The Engineer’s Manual of Construction Site Planning

division of the general work front into working sections, if

the technological conditions and job safety allow it, to ensure

earlier beginning of subsequent works;

increasing the number of shifts.

As the shortening of the duration of construction is generally

connected to a change in cost price, the following must be

borne in mind:

shortening the duration of construction is gained only by

shortening the duration of tasks on the critical path;

when the overall construction duration is gradually short-

ened, initially non-critical work chains on the network chart

will become increasingly critical, that is the amount of tasks

in need of shortening will grow equal to the square of the

time shortened;

when decreasing the duration of construction using a multi-

shift division of work, the amortisation costs of construction

machinery will decrease, while the costs for transport,

assembly and disassembly of machinery will increase; how-

ever, running costs will stay constant (machine operator’s

wage, fuel consumption, costs for electricity, lubricants,

repair and maintenance);

working efficiency is up to 10% lower in the evening shift

and up to 15% lower in the night shift, because:

r there is inevitable loss of time when changing shifts,

r inconvenience from evening and night work influences

worker productivity (artificial lightning, etc.) and

complicates coordination work with third parties,

Outline of site management after contractsignature 41

r the number of on-the-job accidents increases,

r there might be a need for additional pay for working on

evening and night shifts.

When deciding which option to choose in order to shorten con-

struction duration, economic calculations should be followed

taking into consideration the aforementioned, and other, sub-

stantial factors for each specific construction project.

After introducing the necessary changes to the work schedule,

the calendared work schedule is calculated.

It follows from this that the compilation of the construction site

layout and time schedule of construction works are mutually

related, therefore finding a satisfying solution might take sev-

eral iterations of the plan. At the same time, there must be a

desire and will to be prepared for multiple calculations of

resource allocation, the drafting of their workloads (workers,

construction machinery, materials, etc.) and payment sched-

ules and the cost estimates for construction site expenses.

As a result of the chronological planning of building manage-

ment, the following documents are drafted:

the organisational/technological model of construction (the

network chart of construction);

the construction work time schedule (Gantt chart);

charts of labour allocation (as a histogram) separately, with

works to be completed by the contractor’s own forces, and

in total;

chart of basic plant allocation;

42 The Engineer’s Manual of Construction Site Planning

chart of financing of works (cumulative) as an appendix to

the contract in order to define contractual payment flow for

the client.

On the basis of the chart of calendared construction work, the

following should be indicated:

deadlines of completion/hand over of missing drawings;

duration of dewatering works;

duration of the use of offices, shelters, warehouses and other

temporary buildings;

duration of the need for construction site fencing;

duration of the need for safety barriers;

duration of the use of scaffolding;

working period of tower crane (and bigger mobile cranes)

on construction site with reference to the need for support

works as well as assembly and disassembly time;

heating duration for construction of the building;

duration of warming period for concrete;

deadlines for delivery of technological equipment;

connection dates for utility networks;

testing dates;

dates for inspections and expertise.

Outline of site management after contractsignature 43

The construction company should create a classification system

for works corresponding to its specialisation that elaborates on

inter-company labour consumption norms or the reciprocal

norms of labour productivity. The availability of this kind of

data system would allow significant economies on costs and

the time spent preparing construction time scheduling.

Table 3.1 presents an example of such a classification along

with possible labour efficiency indicators. The numerical val-

ues should only be interpreted as an example illustrating the

considerable variation of labour efficiency by type of work to

assure the expediency of compiling such standards as well as

the need for their periodic adjustment.

The technological/organisational solutions for erecting

many buildings are similar due to their similar structural

solutions. Therefore, it is practical for large construction

companies and consulting site planning firms to form a cata-

logue of standardised network charts that represents the

majority of technological and organisational descriptions of

buildings. The catalogue of network charts of a custom main

contractor usually consists of no more than ten to twenty

types of charts.

An example of a list of types (they vary by composition of

construction work, sequence and reference) is as follows:

construction of a multi-storied framed apartment building;

construction of a multi-storey cast-in-situ concrete apart-

ment building;

construction of multi-storey brick house;

construction of a multi-storey office building;

44 The Engineer’s Manual of Construction Site Planning

Table 3.1: Example of construction work classification

Number or

Code

Work Labour productivity

in€ per man-day

1 Building site set up 80

2 Temporary buildings and

facilities

90

3 Earth works (by machine) 238

4 Earth works (manual) 13

5 In situ concrete foundations 86

6 Precast concrete foundations

7 Foundation for technological

equipment

60

8 Backfilling (by machine) 142

9 Backfilling (manual) 14

10 Erection of precast concrete

frame

11 Erection of steel frame 159

12 Erection of precast sandwich

panels

13 Construction of building

envelope

102

14 Installation of doors and gates 179

15 Installation of windows 110

16 Roof works 118

17 Construction of large concrete

floors

18 Construction of small concrete

floors

52

19 Construction of tile floors 83

20 Construction of roll-material

floors

123

21 Inside plastering works 17

22 Inside painting works 24

23 Inside tiling works 52

24 Exterior plastering works 23

25 Exterior painting works 21

26 Ventilation works 152

27 Internal water supply and

sewage works

76

(Continued)

Outline of site management after contractsignature 45

construction of a single-storey framed industrial building;

construction of a multi-storey industrial building;

construction of a petrol station;

construction of a department store;

construction of a waterworks;

construction of a sewage treatment plant.

Number or

Code

Work Labour productivity

in€ per man-day

28 Installation of sanitary ware 97

29 Heat insulation works 81

30 Interior electrical works/

installation of cables

93

31 Installation of lighting 169

32 Interior low-current works 86

33 Assembly of automatic

equipment

144

34 Assembly of technical

equipment

201

35 Site levelling 247

36 On-site water supply and

sewage works

106

37 On-site heating pipelines 73

38 On-site electric installations 171

39 On-site communication

installations

88

40 Construction of on-site roads

and paved areas

139

41 Greenery works 113

42 Construction of fencing 88

43 Other works 76

Table 3.1: (Cont'd)

46 The Engineer’s Manual of Construction Site Planning

Construction time schedule for use in planning site manage-

ment during the contracting period has to be more detailed

than time schedule in bidding phase shown in Figure2.1.

3.5 Calculation of site work quantities and

estimate of costs

To simplify cost estimation of site planning and temporary

works, the unification and standardisation of corresponding

costs is necessary. For that purpose it is necessary to aggregate

subsequent site work element costs estimated by unit prices

(analogous to direct costs) into 15 standardised groups corre-

lated with the nomenclature of the aggregated costs of the

bidding stage (see Section 2.5). Therefore, feedback is used to

automate the formation of norms for the first stage of site

management.

This means that at this stage construction site costs are esti-

mated as direct costs of the construction, given at the level of

unit prices. The designer of the construction site management

will compile a bill of quantities of temporary works and the

respective list of necessary resources, which are estimated by

the construction company’s quantity surveyor.

The resource requirements appertaining to the bill of quantities

should be given according to the resource ordering form used

in the company, if such a form is created, and should be printed

out separately.

Presented in Table3.2 is a list of costs (resources) that refers to

the initial data in order to determine costs according to the

construction site layout (CSL), time schedule (TS) or to stand-

ards and procedures of calculating a bill of quantities. The

abbreviations TS and CSL in the table point to the source from

Outline of site management after contractsignature 47

Table 3.2: List of costs for temporary and building site management works

Cost Measurement

unit

Information

source

Code Description of cost element

and cost group

Group Element CSL TS

1 Cranes and other lifting devices

1.1 Tower cranes (for

calculations see Chapter 4)

1.1.1 Number and type of

cranes

Machine shift + +

1.1.2 Crane way base m

2

+

1.1.3 Crane way track modules Piece +

1.1.4 Crane way safety fencing m +

1.1.5 Test load t +

1.1.6 Load take up devices by

type

Piece +

1.1.7 Switchboards Piece +

1.2 Mobile cranes Machine shift + +

1.3 Hoists and elevators Machine shift + +

1.4 Other lifting devices Machine shift + +

2 Construction site fencing

2.1 Guard fencing m; m

2

+

2.2 Safety fencing m +

2.3 Gates Piece; m +

2.4 Billboard with

construction data (owner,

contractor, designer,

dates,etc.)

Piece; m

2

+

2.5 Protection barrier for trees Piece; m

2

+

3 Temporary roads and storage sites

3.1 Earthworks m

2

; m

3

+

3.2 Road covering m

2

; m

3

3.3 Open air storage covering m

2

; m

3

3.4 Location for receiving of

concrete and mortar

Place

3.5 Pre-assembly area m

2

3.6 Waste storage area,

containers

m

2

; piece +

3.7 Traffic signs piece + +

48 The Engineer’s Manual of Construction Site Planning

Cost Measurement

unit

Information

source

Code Description of cost element

and cost group

Group Element CSL TS

4 Temporary water supply

4.1 Common water pipes m +

4.2 Piping for fire brigade

water

m+

4.3 Fire brigade hydrants piece +

4.4 Water requirement for