HELMET- 870257

Page 1 of 86

D3.1 High-Level Design Document

D3.1 High-Level Design Document

Due date of deliverable: 01/09/2020

Actual submission date: 01/09/2020

Leader/Responsible of this Deliverable: Omar Garcia Crespillo (DLR)

Reviewed (Y/N): Y

Document status

Revision

Date

Description

01

01/09/2020

1

st

Official Release

Dissemination Level

PU

Public

X

CO

Confidential, restricted under conditions set out in Model Grant Agreement

CI

Classified, information as referred to in Commission Decision 2001/844/EC

Start date of project: 02/01/2020

Duration: 24 months

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under GA No 870257

Ref. Ares(2020)4537864 - 01/09/2020

HELMET- 870257

Page 2 of 86

D3.1 High-Level Design Document

CONTRIBUTING PARTNER

Name

Company

Roles/Title

Omar Garcia Crespillo

DLR

WP3 Leader & Contributor

Anja Grosch

DLR

Contributor

Matthias Fehr

DLR

Contributor

Chen Zhu

DLR

Contributor

Aleš Filip

UPA

Contributor

Filip Holík

UPA

Contributor

Alessandro Neri

RDL

Contributor

Maurizio Salvitti

RDL

Contributor

Cesare Dionisio

RDL

Contributor

Panagiotis Xefteris

RDL

Contributor

Pietro Salvatori

RDL

Contributor

Roberto Capua

SGI

Contributor

Luca Gattuso

SGI

Contributor

Manuele Innocenti

SGI

Contributor

Marco Giangolini

SGI

Contributor

Ondrej Kutik

RBA

Contributor

Miroslav Krajíček

RBA

Contributor

Michael Loupis

ITC

Contributor

John Spanoudakis

ITC

Contributor

DISTRIBUTION LIST

Name

Company

Roles/Title

Alessandro Neri

RDL

Project Coordinator

Daniel Lopour

GSA

GSA Programme Officer

Eutimio Tiliacos

GSA

Reviewer

Jose Eugenio Naranjo

GSA

Reviewer

Maurizio Salvitti

RDL

Project Manager

Aleš Filip

UPA

WP2 Leader

Omar Garcia Crespillo

DLR

WP3 Leader

Ondrej Kutik

RBA

WP4 Leader

Pietro Salvatori

RDL

WP5 Leader

Roberto Capua

SGI

WP6 Leader

APPROVAL STATUS

Document Code

Rev.

Role

Approved

Authorised

Date

HELMET_D3.1

01

WP3 Leader

O.Garcia Crespillo (DLR)

-

01/09/2020

Coordinator

A.Neri (RDL)

A.Neri (RDL)

01/09/2020

HELMET- 870257

Page 3 of 86

D3.1 High-Level Design Document

EXECUTIVE SUMMARY

This document is the deliverable D3.1 High-Level Design Document which describes the design

of the high-level HELMET architecture with focus on the main general architecture solutions for the

augmentation network subsystem as well as the general architecture solution for the onboard

subsystem for each transportation segments. This deliverable starts by reviewing the user and

system requirements as specified in deliverable D2.3. Then, it presents the HELMET high-level

architecture solutions for augmentation, rail, automotive and UAV at general subsystem level. The

general subsystem architecture is then used to convert the system and user requirements to the

subsystem level including the traceability matrix at subsystem level. This document then tackles the

identification of the technological gaps to satisfy such requirements. Finally, this document also

covers the high-level design of the record and playback unit that will be used during HELMET project.

HELMET- 870257

Page 4 of 86

D3.1 High-Level Design Document

TABLE OF CONTENTS

CONTRIBUTING PARTNER .................................................................................................................................. 2

DISTRIBUTION LIST ............................................................................................................................................ 2

APPROVAL STATUS ............................................................................................................................................ 2

EXECUTIVE SUMMARY ....................................................................................................................................... 3

TABLE OF CONTENTS ......................................................................................................................................... 4

LIST OF FIGURES ................................................................................................................................................ 6

LIST OF TABLES .................................................................................................................................................. 7

DEFINITION AND ABBREVIATIONS ..................................................................................................................... 8

1. INTRODUCTION ........................................................................................................................................... 12

2. REVIEW OF SYSTEM REQUIREMENTS .......................................................................................................... 13

2.1 Proposed System Requirements review and justifications ................................................................... 13

2.2 Summary of System Requirements ....................................................................................................... 15

3. HIGH-LEVEL MULTIMODAL SYSTEM DESIGN ............................................................................................... 17

4. MULTIMODAL AUGMENTATION INTEGRITY MONITORING HIGH LEVEL DESIGN ....................................... 18

5. HIGH LEVEL ARCHITECTURE FOR RAILWAY APPLICATION ........................................................................... 20

5.1 Railway principles used for safe architecture design ............................................................................ 21

5.2 Architecture_1: Reactive Fail-Safety for along track Train position determination ............................. 22

5.2.1 Markov model of reactive LDS ................................................................................................ 22

5.2.2 Derivation of Time to Fault Detection and Negation .............................................................. 24

5.2.3 Numerical verification of meaning of LDS state probabilities ................................................. 26

5.2.4 Interpretation of T

DN

as P

md

..................................................................................................... 27

5.2.5 Proposed Safety Monitor for run-time safety evaluation ....................................................... 28

5.2.6 Steps in Safety Monitor design ................................................................................................ 28

5.2.7 Example: Derivation of time to failure detection and negation (T

DN

) ..................................... 29

5.2.8 Example: Determination of P

md

for GNSS+AIMN-based ATP failure ....................................... 29

5.2.9 Example: MDE determination ................................................................................................. 30

5.3 Architecture_2: Composite Safety for Track Identification ................................................................... 31

5.3.1 Rules for realization of safety related functions with TFFR < 1e-9/ hour (EN 50129, IEC 61508)

33

5.3.2 AND-combination logic ............................................................................................................ 33

5.3.3 High-level composite LDS architecture for Track Identification based on track-side data ..... 34

5.3.4 Rail track-side infrastructure sensing ...................................................................................... 38

5.3.5 High-level composite LDS architecture for Track Identification in stand-still mode ............... 45

5.3.6 Cold Movement Detector in ERTMS baseline 3....................................................................... 47

HELMET- 870257

Page 5 of 86

D3.1 High-Level Design Document

5.3.7 Cold Movement Detector based on GNSS: proposed solution ............................................... 47

5.4 Overview of safety techniques Selection foR LDS ................................................................................. 48

6. HIGH LEVEL ARCHITECTURE FOR AUTOMATED VEHICLES APPLICATION .................................................... 49

6.1 General Approach and Considerations .................................................................................................. 49

6.1.1 High-level Architecture Design ................................................................................................ 50

6.2 High-level Localization Modes of Operation ......................................................................................... 51

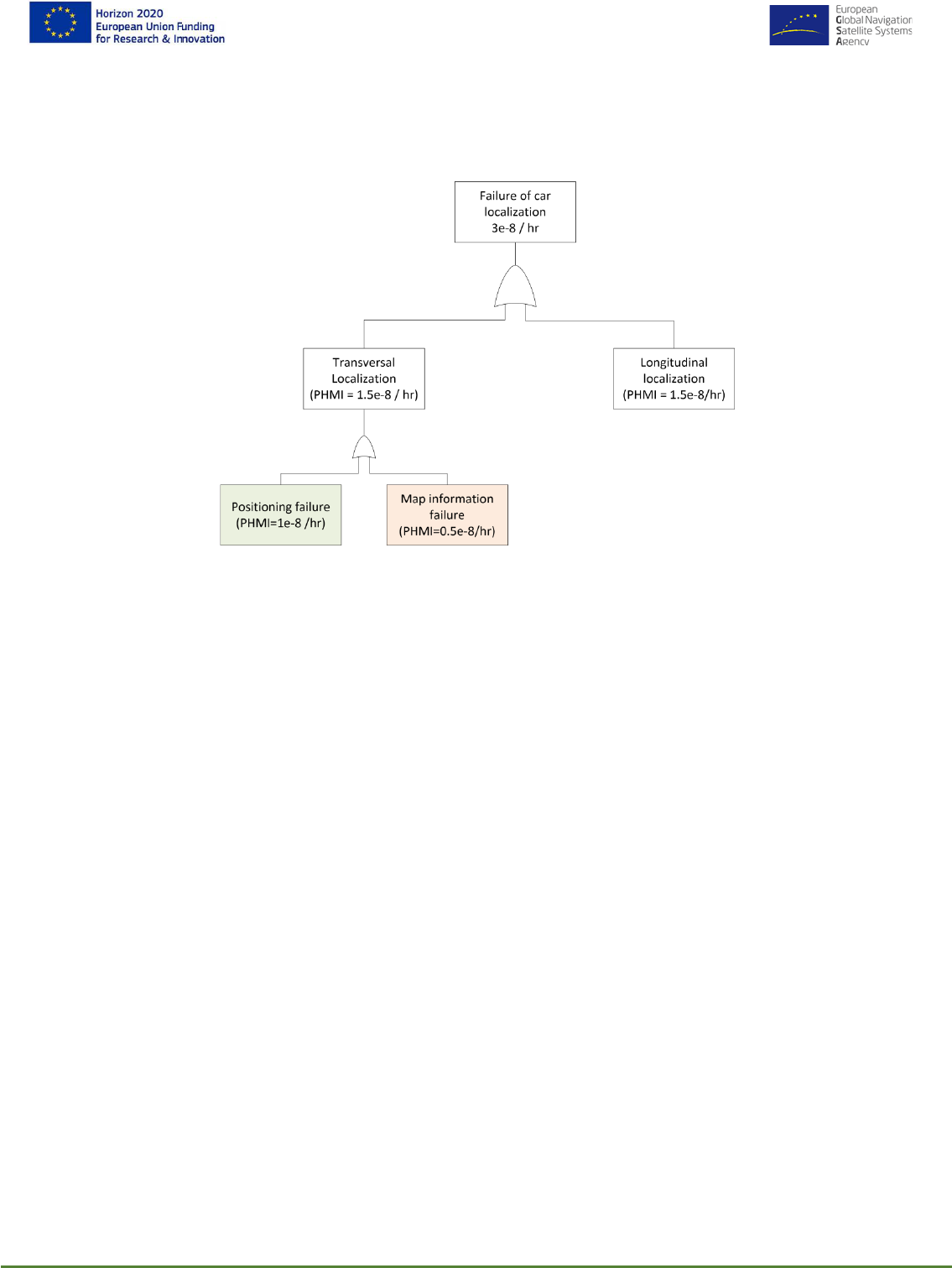

6.3 Fault Tree Analysis for Automated Vehicles .......................................................................................... 52

7. HIGH LEVEL ARCHITECTURE FOR UAS APPLICATION ................................................................................... 56

8. CONVERSION OF SYSTEM REQUIREMENTS TO SUBSYSTEM LEVEL ............................................................. 62

8.1 AIMN Subsystem Requirements ............................................................................................................ 62

8.2 railway segment Subsystems Requirements ......................................................................................... 67

8.3 automotive segment Subsystems Requirements .................................................................................. 72

8.4 UAV segment Subsystems Requirements ............................................................................................. 74

9. TECHNOLOGY CAPABILITY GAPS.................................................................................................................. 77

10. RECORD AND PLAYBACK SYSTEM (RPS) ..................................................................................................... 79

10.1 System requirements decomposition ................................................................................................. 81

11. CONCLUSIONS ........................................................................................................................................... 84

12. REFERENCES ............................................................................................................................................... 85

HELMET- 870257

Page 6 of 86

D3.1 High-Level Design Document

LIST OF FIGURES

Figure 1: General design flow ....................................................................................................... 12

Figure 2: Overview of different design levels and their dependency .............................................. 13

Figure 3: In-lane vehicle localization/positioning ........................................................................... 14

Figure 4: Multi-modal positioning and localization system ............................................................. 17

Figure 5: Augmentation Network High Level Design ..................................................................... 18

Figure 6. Fail-safe techniques according to CENELEC: (a) composite fail-safety, and (b) reactive fail-

safety. ........................................................................................................................................... 21

Figure 7: Reactive LDS safety structure based on HELMET AIMN and independent diagnosis,

including Markov model ................................................................................................................ 23

Figure 8: Probability of failure as a function of HR

Non-Train(SIS)

and T

DN

............................................ 25

Figure 9: Safety monitor in FTA diagram. ...................................................................................... 27

Figure 10: Determination of Minimum Detectable Error (MDE) and maximal decision Threshold T

max

..................................................................................................................................................... 28

Figure 11: Determination of P

md

from duration of GNSS+AIMN-based ATP failure T

DN

................. 29

Figure 12: Markov model of two- channel LDS (2oo2) without failure detection ............................ 32

Figure 13: Principal composite safety LDS architecture intended for Track Identification function . 35

Figure 14: FTA of the LDS with composite safety: technical and operational safety measures have

been introduced to meet the required THR < 1e-9/ hr for main LDS hazard. ................................. 36

Figure 15: FTA of LDS with applied specific technical and operational safety measures. Examples

of minimum THR/TFFR requirements for individual functions in the composite solution are marked

in red) ........................................................................................................................................... 37

Figure 16: Train routing detection on switch by means of gyro-odometry: (a) based on double

heading differences (DHDs), and (b) complementary diagrams of heading differences for ride in

deflecting direction (above) and in straight direction . .................................................................... 39

Figure 17: Heading differences vs. travelled distance on the switch .............................................. 41

Figure 18: The posterior probability P(H

1

|A) of the routing detection vs. travelled distance on the

switch ............................................................................................................................................ 42

Figure 19. Fundamental elements of rail switch [12] ..................................................................... 42

Figure 20: Detection of guard rail to get information on train routing ............................................. 43

Figure 21: Switch with "self-guarding cast manganese" frog without guard rails [13] ..................... 43

Figure 22: Switch with movable frog without guard rails [14], [15] ................................................. 44

Figure 23: Principle of guard rail detection using laser sensor – works well in snow on track (tested

in operations) ................................................................................................................................ 44

Figure 24: Detection of guard rail using inductive proximity sensor ............................................... 45

Figure 25: FTA of composite safety LDS in case when train position is determined in stand-still .. 46

Figure 26: General Onboard unit Subsystem Architecture ............................................................ 50

Figure 27: General FTA Auto ........................................................................................................ 53

Figure 28: Auto Candidate solution 1 (FTA) .................................................................................. 54

Figure 29: FTA Analysis Positioning Auto (Candidate solution 2) .................................................. 55

Figure 30: UAV system architecture .............................................................................................. 56

Figure 31: Integrated functional architecture of UOBU for navigation ............................................ 59

Figure 32: UOBU conceptual design with two WFOW cameras .................................................... 60

Figure 33: UOBU conceptual simplified internal architecture ......................................................... 60

Figure 34: UOBU conceptual simplified internal architecture ......................................................... 61

Figure 35: Block diagram of ARCHITECTURE_1 with allocated subsystem requirements ............ 68

HELMET- 870257

Page 7 of 86

D3.1 High-Level Design Document

Figure 36: Block diagram of ARCHITECTURE_2 with allocated subsystem requirements ............ 70

Figure 37: Sensor and Recording unit architecture ....................................................................... 80

LIST OF TABLES

Table 1: Summary of Localization system requirements ............................................................... 16

Table 2: Localization Modes of Operation ..................................................................................... 52

Table 3: Preliminary operation modes supporting application scenarios ....................................... 52

Table 4: Augmentation System Service Level Definition ............................................................... 63

Table 5: Level to Augmentation Systems allocation ...................................................................... 64

Table 6: Augmentation Subsystem Requirements Review ............................................................ 64

Table 7: System Requirements for Localization System Rail – ARCHITECTURE_1 ..................... 68

Table 8: System Requirements for Localization System Rail – ARCHITECTURE_2 ..................... 71

Table 9: Subsystem requirements for Localization System Automotive ......................................... 72

Table 10: Subsystem requirements for Localization System UAS ................................................. 74

HELMET- 870257

Page 8 of 86

D3.1 High-Level Design Document

DEFINITION AND ABBREVIATIONS

Acronym

Description

A

Availability

ABIA

Avionics Based Integrity Augmentation

ADS-B

Automatic Dependent Surveillance - Broadcast

AIMN

Augmentation and Integrity Monitoring Network

AL

Alert Limit (defined by user)

ARAIM

Advanced Receiver Autonomous Integrity Monitor

ASIL

Automotive Safety Integrity Level

ATP

Along Track Position / Positioning

ATPL

Along Track Protection Level

BTM

Balise Transmission Module

CAN

Controller Area Network

CC

Control Center

CCF

Common Cause Failure

CCS

Control Command and Signalling

CCS TSI

Control Command and Signalling Technical Specifications for

Interoperability

CENELEC

Comité Européen de Normalisation Électrotechnique

CGS

Control Ground Station

CHK

Check

CMD

Cold Movement Detector / Detection

CNPC

Control and Non-Payload Communications

CONOPS

Concept of Operations

DaA

Detection and Avoidance

DB

Track Database

DCB

Differential Code Bias

DHD

Double Heading Differences

DTE

Driving Technical and control Error

E/E/PE

Electrical/Electronic/Programmable Electronic

EDAS

EGNOS Data Access Service

EGNOS

European Geostationary Navigation Overlay Service, i.e. European

SBAS

EM

electro magnetic

ERSAT GGC

ERTMS on SATellite – Galileo Game Changer

ERSAT-EAV

ERTMS on SATellite – Enabling Application & Validation

ERTMS

European Rail Traffic Management System

ETCS

European Train Control System

EU

European Union

EUREF

IAG Reference Frame Sub-Commission for Europe

EVC

European Vital Computer

FDE

Fault Detection and Exclusion

FDIR

Fault Detection, Isolation and Recovery

FEE

Front End Electronics

FOG

Fibre Optic Gyroscope

HELMET- 870257

Page 9 of 86

D3.1 High-Level Design Document

FR

Failure Rate

FTA

Fault tree Analysis

Galileo

European GNSS

GBAS

Ground Based Augmentation System

GCS

Ground Control Station

GEO

Geostationary Earth Orbit satellite

GNSS

Global Navigation Satellite System

GNSS Rx(rx)

GNSS Receiver

GPS

Global Positioning System

GRSP

Galileo Reference Service Provider

GSA

European Global Navigation Satellite Systems Agency

HAS

High Accuracy Service

HELMET

High integrity EGNSS Layer for Multimodal Eco-friendly

Transportation

HR

Hazard Rate

HPL/VPL

Horizontal/Vertical Protection Level

IMTM

Inspection, Monitoring and Traffic Management

IMTM UAS/RPAS-PI

Inspection, Monitoring and Traffic Management + Unmanned Aircraft

System / Remotely Piloted Aircraft Systems. In this PIT station the

UA/RPA can land and refuel batteries based for instance on a non

contact equipment.

IMU

Inertial Measurement Unit

INDEP-CHK

Independent Check

INS

Inertial Navigation System

K

fa

Coefficient of False Alert

K

md

Coefficient of Missed Detection

KVH FOG

KVH (i.e. name of company) Fibre Optic Gyroscope

LDS

Location Determination System

LiDAR

Light Detection and Ranging

LNA

Low-Noise Amplifier

MA

Movement Authority

MDE

Minimum Detectable Error

MEMS

Micro Electro Mechanical Systems

METEO

Meteorological Conditions

MFMC

Multi frequency Multi-constellation

MI

Misleading Information

MOBU

Multi-sensor On-Board Unit platform

MTBF

Mean Time Between Failure

MTTF

Mean Time to Failure

MTTR

Mean Time to Repair

NAV

Navigation

NAVAIDS

Navigational Aids

NLOS

Non-line-of-sight reception

NMEA

National Marine Electronics Association

NP

No Power

NRTK

Network RTK

NTRIP

Networked Transport of RTCM via Internet Protocol

HELMET- 870257

Page 10 of 86

D3.1 High-Level Design Document

OBU

On-Board Unit

PF

Probability of Failure (average) per 1 hour

PHMI

Probability of Hazardously Misleading Information

PIT-Station

On ground Service Station

PL

Protection Level

Pmd

Probability of Missed Detection

PPK

Post-Processing Kinematics

PPP

Precise Point Positioning

PPP-AR

PPP Ambiguity Resolution

PPS

Pulse Per Second

PTP

Precision Time Protocol

PVT

Position, Velocity, Time

QoS

Quality of Service

RAIM

Receiver Autonomous Integrity Monitor

RBC

Radio Block Centre

RF

Radio Frequency

RHINOS

Railway High Integrity Navigation Overlay System – H2020 project

RIMS

Ranging Integrity Monitoring Stations

RIU

Receiver Interpolation Uncertainty

RNP

Required Navigation Performance

RPS

Remote Pilot Stations

RS

Reference Station network

RTCM

Radio Technical Commission for Maritime Services

RTK

Real Time Kinematics

RTM

Requirements Traceability Matrix

RXFE

Receive Front End

SBAS

Satellite Based Augmentation System: e.g.: EGNOS, WAAS, MSAT,

SDCM, GAGAN

SDC

Self-Driving Car

SDR

Software-Defined Radio

SDT

Safe Down Time

SIL

Safety Integrity Level

SIS

Signal-In-Space

SNR

Signal to Noise Ratio

SoL

Safety of Life

SOM

Start of Mission

SR

Staff Responsible

SSR

State Space Representation

SW

Software

TDN

Time to failure Detection and Negation

TFFR

Tolerable Functional Failure Rate

THR

Tolerable Hazard Rate

TPL

Train Position Locator

TT&C

Telemetry, Tracking & Command

TTA

Time-To-Alert

U

Unavailability

HELMET- 870257

Page 11 of 86

D3.1 High-Level Design Document

UA/RPA

Unmanned Aircraft/ Remotely Piloted Aircraft

UART

Universal Asynchronous Receiver/Transmitter

UAS

Unmanned Aircraft System

UAS/RPAS

Unmanned Aircraft System / Remotely Piloted Aircraft Systems

UAV

Unmanned Aerial Vehicle

UNISIG

Union Industry of Signalling

UOBU

UAS On Board Unit

UTM

Unmanned Aircraft System Traffic Management; UAV Traffic

Management

VB

Virtual Balise

VBN

Visual Based Navigation

VBR

Virtual Balise Reader

VTOL

Vertical Take-Off and Landing

WFOV

Wide Field of View

ZTD

Zenith Tropospheric Delay

HELMET- 870257

Page 12 of 86

D3.1 High-Level Design Document

1. INTRODUCTION

In deliverable D2.3 the user and system requirements are defined and specified. The architecture of

the system from multiple levels is designed progressively based on the requirements, as shown by

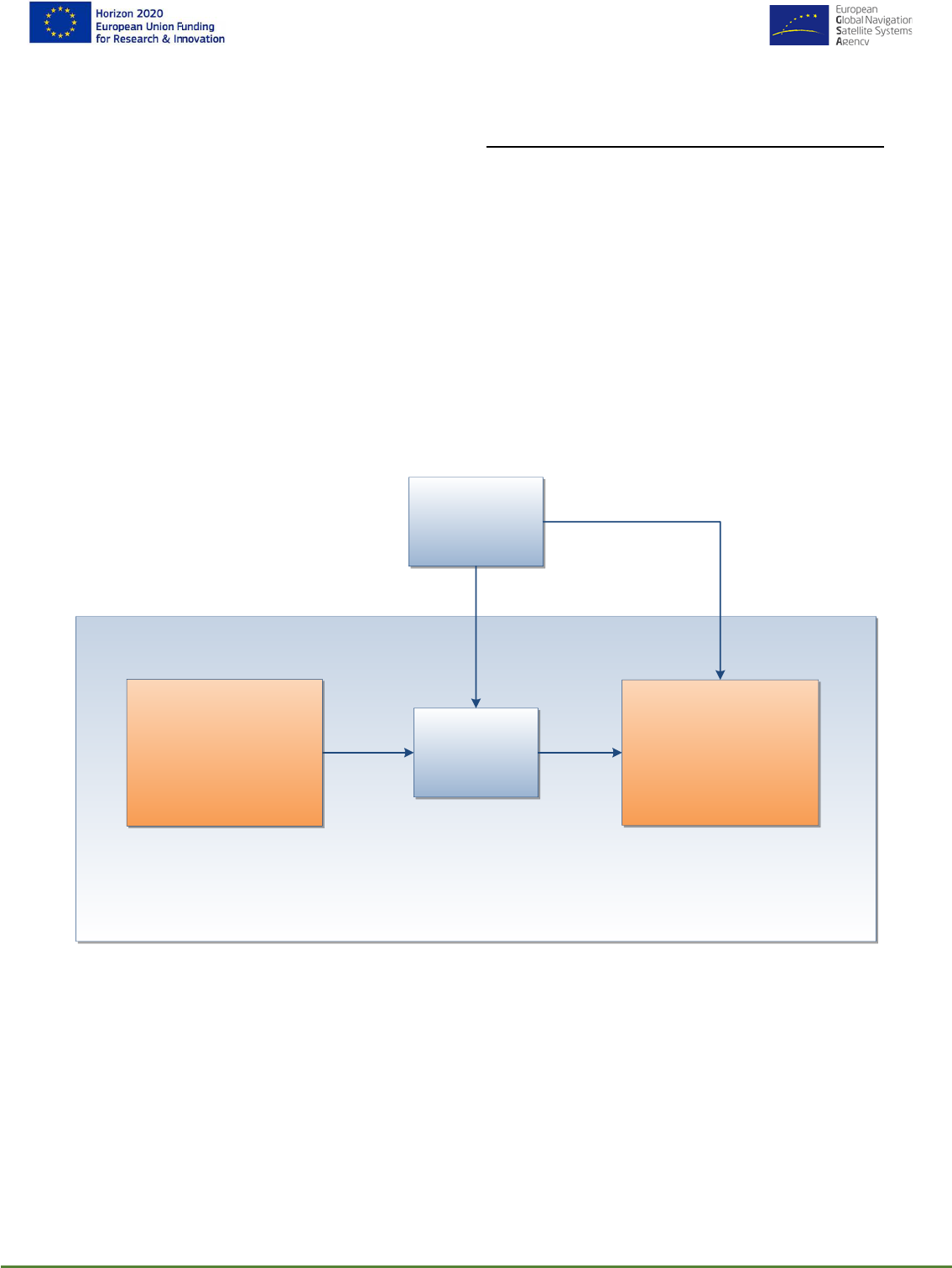

the dependency diagram in Figure 1.

User Requirements

User Functional

Requirements

System Requirements

High Level System

Design (D3.1)

Functional Architecture

Design (D3.2)

Detailed Design (D3.3)

Figure 1: General design flow

Based on the user and system requirements, the multimodal positioning and localization system

architecture is proposed so that the requirements can be fulfilled. Figure 2 clarifies the division of

different hierarchies used for the system design. The high level design implies the architecture on

the system and subsystem level in the context.

HELMET- 870257

Page 13 of 86

D3.1 High-Level Design Document

Figure 2: Overview of different design levels and their dependency

2. REVIEW OF SYSTEM

REQUIREMENTS

This section reviews and summarizes the system level requirements from D2.3 [2] related to the

vehicle localization system.

2.1 PROPOSED SYSTEM REQUIREMENTS

REVIEW AND JUSTIFICATIONS

The System Requirements for the multi-modal HELMET solution have been derived from the

HELMET high-level User Requirements, with the identification of constraints and limitations,

specifying models and architectures of RAIL, AUTO and UAVs in order to perform an accurate safety

analysis.

The requirements of railway applications are specified in section 5.1 of D2.3 [2]. Compared with the

railway application, the road traffic has more diversity in the vehicles and environments, which also

results in diverse requirements. The system requirements as functions of vehicle dimensions as well

as the road and lane width are analysed in section 5.2 of D2.3 [2]. In this section, we calculate

specific quantitative requirements for automotive with some typical values in order to better guild the

following system design and development.

The most demanding requirement comes from the lateral dimension of the in-lane vehicle

localization, which is defined by the following equation in D2.3 (and illustrated by Fig. 2) [2]:

where

and

are the width of the lane and the vehicle respectively, and

is the

maximum driving technical and control error.

HELMET- 870257

Page 14 of 86

D3.1 High-Level Design Document

Figure 3: In-lane vehicle localization/positioning

In order to align the common requirements on the localization system in different traffic models, we

investigate the specified requirements according to typical values of the parameters in Europe.

Concerning the EU road definition, application, velocity, dimensions, presence of traffic lights / tolling

stations have to be taken into account.

Although different road design principles are adopted in single countries, a typical width of 3,50 m to

3,75 m (https://ec.europa.eu/transport/road_safety/sites/roadsafety/files/pdf/ersosynthesis2018-

motorways.pdf) is considered in Europe. According to the following link about European lane widths

(https://en.wikipedia.org/wiki/Lane), it could be assumed:

▪ V (highway/local/narrow) = 80-130 / 60-90 / 20-60 [km/h]

▪ Width lane (highway/local/narrow) = 3.75 / 3.25 / 2.75 [m]

The lane width is of particular interest mainly in the derivation of the lateral AL and correspondent

accuracy.

About the car sizes, we have to try to adapt the needs to the European car market: from the following

link (https://www.automobiledimension.com/car-search-engine.php), searching for cars with

maximum width W, length L and height H, the maximum values obtained are (usually related to a

VAN vehicle):

W / L / H = 1.986 / 5.4 / 1.977 [m] ≤ 2 / 5.4 / 2 [m]

For longitudinal dimension, the main constraint on longitudinal AL comes from the curves, where the

vehicle must ensure to keep itself in the lane when passing these parts of the highway. More detailed

analysis can be found in D2.3 [0], which results in the following equation and table:

The curve radius of the road depends on the road type and might differ from country to country.

The minimum allowed radii are in relation to the designed speed requirement of the road has already

been provided in Table 13 from D2.3 [2]. In addition, on local and narrow road, there is an additional

Car width

Lane width

HELMET- 870257

Page 15 of 86

D3.1 High-Level Design Document

requirement that the vehicle must stop at least one meter before any crossing or traffic light. Hence,

the AL for longitudinal AL is set no smaller than one meter. For highways, there is no such constraint.

Exploiting the following typical values from our analysis and references as input data for the above

reviewed equations from D2.3 [2]:

▪ W

veh

/ L

veh

= 2 / 5.4 [m] (on the basis of the maximum dimensions currently available derived

by the above link)

▪ Wlane (highway/local/narrow) = 3.75 / 3.25 / 2.75 [m]

▪ Minimum road radius (highway/local/narrow) = 240 / 120 / 10 [m]

▪ DTE

max

= 0.2 [m]

we obtain the values listed in the Table 1 “Summary of Localization System Requirements”.

It can be seen that with a narrow road width less than 3 m, the AL and positioning accuracy

requirements might be challenging to achieve with high availability by considering the currently

available technologies. We will further mention this point in the technology capability gap section

(section 9).

The integrity risk for automated driving should not exceed 1e-6, according to the report from GSA

[16]. From the integrity risk and the alert limit we can derive the corresponding 95% accuracy

requirement. In HELMET we will investigate if it is possible to achieve even higher integrity to further

ensure safety.

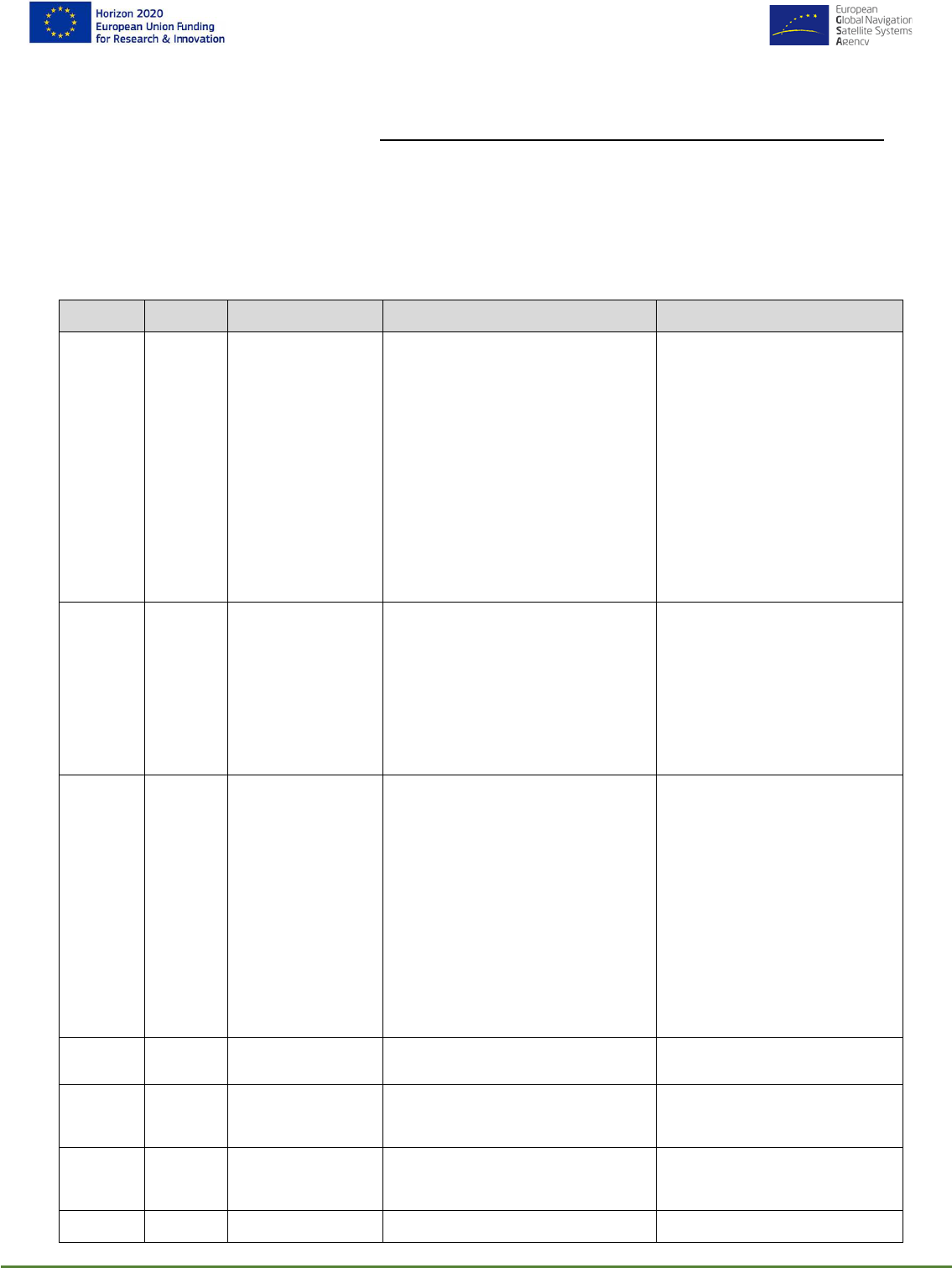

2.2 SUMMARY OF SYSTEM REQUIREMENTS

According to the review and justification in the last section, the system requirements for different

models are summarized in Table 1.

HELMET- 870257

Page 16 of 86

D3.1 High-Level Design Document

Table 1: Summary of Localization system requirements

Application

Scenario

User requirement / Use case

Integrity

Accuracy 95%

Alert Limit

Time-to-Alert

Availability

Continuity

Security

RAIL

Localization

system

Track Identification

<1e-9/h

0.7 m

(SR-OBU-PER-006.a)

1.785 m

(SR-OBU-SAF-

005.a)

10s - 30 s

(SR-OBU-FUN-007.a)

High

NA

Very high

Odometry Calibration

<1e-9/h

0.7 m

(SR-OBU-FUN-010.a)

1.7 m

(SR-OBU-SAF-

011.a)

< 1 s

(SR-OBU-SAF-012.a)

High

NA

Very high

Cold Movement Detection

<1e-9/h

2 m

(SR-OBU-FUN-014.a)

5 m

(SR-OBU-SAF-

013.a)

< 10 s

(SR-OBU-SAF-015.a)

High

NA

Very high

AUTO

Localization

system

Automated Driving on

Highway

1e-6/h

27.6 cm lat

(SR-OBU-PER-103.a)

4.58 m long

(SR-OBU-PER-108.a)

67.5 cm lat

(SR-OBU-SAF-

102.a)

11.2 m long (SR-

OBU-SAF-117.a)

1 s

(SR-OBU-SAF-108.a)

> 99.5%

(SR-OBU-SAF-

110.a)

High

(SR-COM-SAF-

120.a)

Very high

(SR-OBU-

SEC-111.a)

Automated Driving on Local

Roads

1e-6/h

17.38 cm lat

(SR-OBU-PER-105.a)

40.9 cm long

(SR-OBU-SAF-118.a)

42.5 cm lat

(SR-OBU-SAF-

104.a)

1 m long

1 s

> 99.5%

High

Very high

Automated Driving on Narrow

and Curved Roads

1e-6h

7.16 cm lat

(SR-OBU-PER-107.a)

11.86 cm long

(SR-OBU-PER-112.a)

17.5 cm lat

(SR-OBU-SAF-

106.a)

29 cm long

(SR-OBU-SAF-

119.a)

1 s

> 99.5%

High

Very high

UAV*

Localization

System

Monitoring Mission

1x10-7/h to

2x10-7/h

1 m /10m hor & vert

~m

1 s

95%-99%

1x10-4/h to 1x10-

8/h

Very high

Inspection Mission

1x10-7/h to

2x10-7/h

1 m /10m hor & vert

~m

1 s

95%-99%

1x10-4/h to 1x10-

8/h

Very high

Traffic Management Mission

1x10-7/h to

2x10-7/h

10m / 30m hor & vert

~m

1 s

95%-99%

1x10-4/h to 1x10-

8/h

Very high

*: Respective system requirement in section 5 of deliverable 2.3 “UAS-AUG-PER-REQ-19” refers to Accuracy/Integrity/Time-to-Alert/Continuity/Availability

HELMET- 870257

Page 17 of 86

D3.1 High-Level Design Document

3. HIGH-LEVEL MULTIMODAL

SYSTEM DESIGN

A preliminary concept of the HELMET architecture has been introduced in D2.3 (as shown in Fig. 31

in [2]). If we extract the common essential part of the localization system for all three means of

transportations, the multi-modal positioning and localization system high level architecture is

illustrated in Figure 4. The system contains two main subsystems: Augmentation Integrity Monitoring

Network (AIMN) and Multi-sensor OnBoard Unit (MOBU). The AIMN provides augmentation and

GNSS integrity messages with different service levels based on a network of infrastructures. The

MOBU subsystem is installed on the vehicles for multiple transportation modes, including railways,

automobiles, and UAVs that supports the transportation tasks. A communication module is required

to transmit the messages and services provided by AIMN and application-specific infrastructures to

the MOBU. For different transportation modes, the localization system also exploits additional

application-specific infrastructures, e.g., balise for railway applications and visual markers for road

applications.

Communication

Link

Multi-modal Positioning and Localization System

Augmentation Integrity

Monitoring Network

(AIMN)

Multi-sensor OnBoard

Unit (MOBU)

Application-

specific

Infrastructures

Figure 4: Multi-modal positioning and localization system

The following chapter 4 describes the high level design of the AIMN with the definition of different

service levels. Chapter 5, 6 & 7 describe the high-level architecture for Railway/Automotive & UAV

applications.

HELMET- 870257

Page 18 of 86

D3.1 High-Level Design Document

4. MULTIMODAL AUGMENTATION

INTEGRITY MONITORING

HIGH LEVEL DESIGN

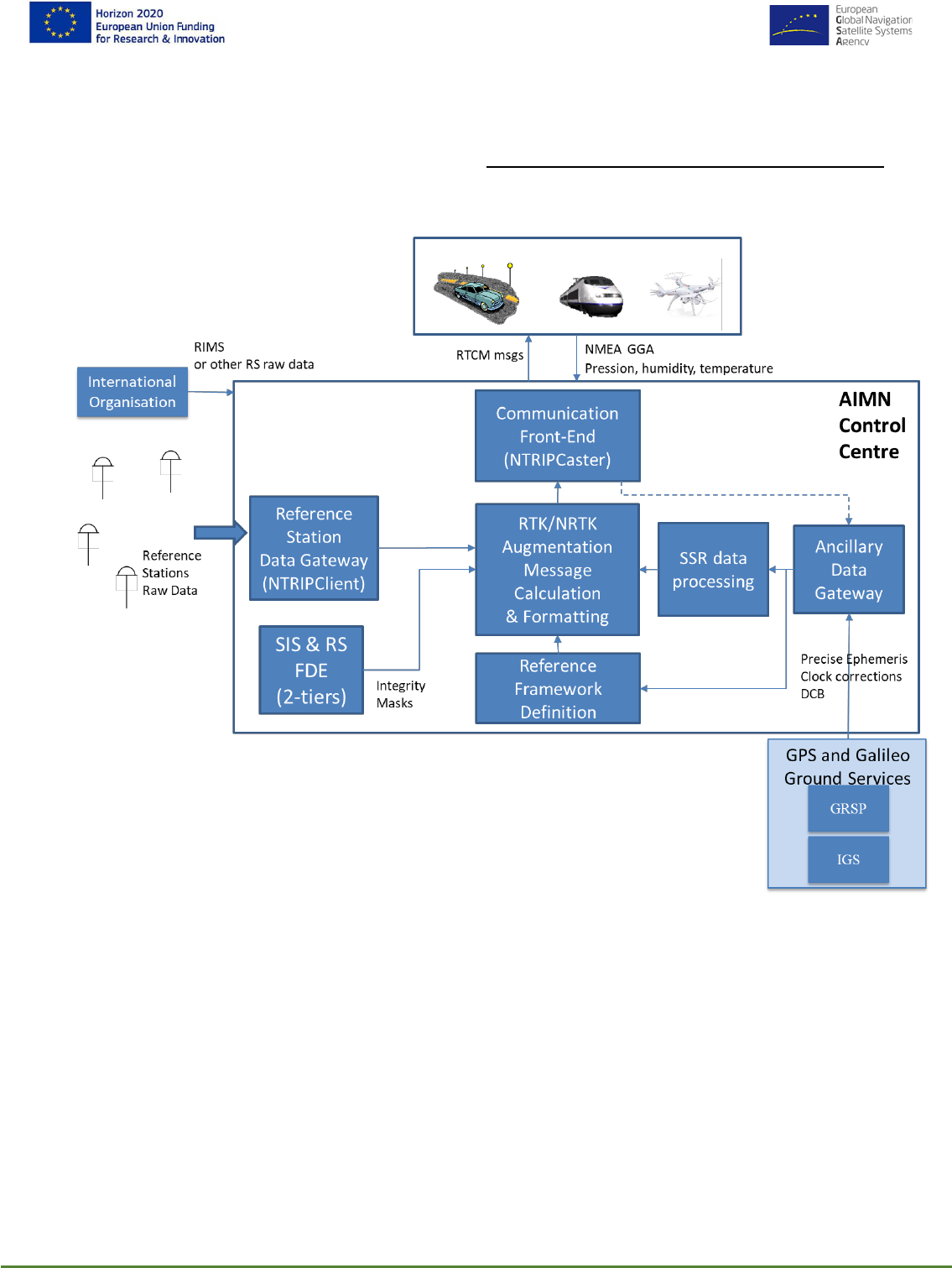

Starting from the high level functional analysis carried out within the D2.3, the Augmentation Network

high level design is represented in Figure 5.

Figure 5: Augmentation Network High Level Design

The AIMN Control Centre take as input the following data:

- International Organisations: International Organisation Reference Stations Raw data can

be used (e.g. EUREF of EDAS RIMS)are used as reference for the implementation of the

first tier of the 2-tiers FDE algorithm

- Reference Stations Raw Data: they are gathered through an NTRIP Client access from

local Augmentation Service providers and are used for the implementation of the second tier

of the 2-tiers algorithm and for the calculation and formatting of the augmentation messages

- GNSS Ground Services: they provide precise ephemeris, clock corrections and differential

code biases needed for the AIMN Reference Framework determination. IGS and the Galileo

Reference Service Provider system are used for GPS and Galileo

HELMET- 870257

Page 19 of 86

D3.1 High-Level Design Document

Users can connect to the AIMN through the single domain Physical Communication system.

Standard NTRIP protocol and RTCM SC-104 formats are used, being it the most implemented

standard for Augmentation data processing into GNSS receivers.

Main subsystems of the Augmentation network and relevant tasks are the following:

- Reference Stations Data Gateway: it implements NTRIP Client access to single Local

Augmentation providers for gathering relevant raw measurements

- Communication Front-End: is an NTRIPCaster publishing mountpoints for the access to

the generated RTCM augmentation messages and the 2-Tiers Integrity masks. It receives

user position for Augmentation Messages calculation

- SIS & RS FDE: the 2-tiers algorithm ([5]), that has been proven to meet SIL-4 THR levels, is

implemented and relevant integrity masks generated for satellites, constellations and

Reference Stations and transmitted to the Augmentation Messages calculation and

formatting for faulted sources exclusion by the user and the network

- RTK/NRTK Augmentation Messages Calculation & Formatting: a quality check on raw

measurements is carried out and RTK messages calculated or Network RTK processing

performed for Reference Stations data generation in the neighbour of the User Receiver

Position. User position id received from the front-end and user for nearest station selection

of NRTK messages generation

- Ancillary Data Gateway: Precise Ephemeris and Clock corrections, Differential Code Biases

and other needed ancillary data are downloaded and used for the Reference Framework

Calculation, errors estimations and SSR parameters gathering from relevant providers.

Tropospheric (e.g. Pressure, Humidity and Temperature) from on the field sensors (e.g. OBU

or Reference Station sensors, if available during the Pilots) can be gathered and processed

for deriving a first level ZTD estimation to be used as a priori information for receivers

estimations. The accuracy of the estimation depends on the quality of the provided data.

Such processing is analysed at functional level, paving the way for a future implementation.

Furthermore, precise Waypoints coordinates (easy detectable by an on board camera, e.g.

Cadastral Fiducial point DB) can be broadcast to the OBU in a suitable format. Such points

can be in a future implementation used by the OBU and merged with angular measurements

for implementing sensor fusion PVT estimations

- SSR Data Processing: basic SR messages (Precise Ephemeris and Clock corrections) are

gathered from external service providers for relevant processing or rebroadcasting. Galileo

HAS corrections messages can be gathered in the same way when transmitted by the Galileo

satellites

Reference Framework Definition: a network adjustment is performed through scientific software

for calculating and updating Reference Stations Coordinates into the ETRF2000 Reference

Framework

AUGMENTATION TO EXTERNAL DOMAIN COMMUNICATION INTERFACES DEFINITION

The Augmentation System Front-End makes available the augmentation messages to the single

domain Communication Front-End (in charge of broadcasting them to the final user) or the OBU in

a widely adopted standard protocol and data format. RTCM is currently the standard format adopted

by the great part of the GNSS receiver manufacturers for the implementation of High Accuracy

Services.

HELMET- 870257

Page 20 of 86

D3.1 High-Level Design Document

Conversion of such Standard to domain specific protocols or formats is in charge of single domain

Communication subsystems or OBU.

5. HIGH LEVEL ARCHITECTURE

FOR RAILWAY APPLICATION

This section deals with the preliminary design of HELMET high-safety integrity LDS architectures for

ERTMS. The preliminary safety design is focused on such LDS solutions to meet user and system

requirements for following functionalities: 1) Track Identification, 2) Odometry calibration, and 3) Cold

Movement Detection. The presented preliminary architectures are designed according to Rail User

Requirement specified in HELMET D2.1 (§4) [1] and Rail System Requirements summarised in

HELMET D2.3 (§5.1 and §7.1) [2].

The first proposed LDS architecture is based on reactive fail-safety with independent diagnosis of

GNSS. The independent GNSS diagnosis utilises ETCS odometry compliant with SIL 4. It is

assumed that LDS initialization including Track Identification has been already performed before

ETCS full supervision started. The main goal of safety analyses performed by Markov modelling is

to demonstrate that the reactive LDS is able to meet THR for the along track position determination

function during nominal train operation (full supervision). Design of key parameters (T

DN

, P

md

, K

md

,

K

fa

, MDE, etc.) of safety monitor/ diagnosis of LDS is outlined. Calculations show that the currently

guaranteed GNSS Integrity Risk for airplane final approach combined with the LDS safety monitor

is able to meet high safety integrity and availability requirements for the ERTMS Virtual balise

concept.

Second, a high-level LDS architecture for Track Identification based on composite safety is

introduced. The composite architecture is intended for LDS initial position determination including

Track Identification during train motion. It is shown that safe LDS initialization can profit not only

from additional on-board sensors for rail infrastructure perception, but also from other external

technical or operational provisions based on track-side data, such as characteristic features of a set

train route (position of switch points) and Movement Authority granted to the train by the Train Control

Centre.

The integral part of the external data is a so called meta data, which characterise the quality of

external LDS data and there are critical for run-time safety evaluation performed by LDS. Fault Tree

Analysis (FTA) demonstrates how significantly can the on-board sensing of infrastructure features

(mainly positions of switches) and external trackside (technical & operational) data contribute to the

reduction of safety requirement for GNSS. Excepting this, efficient experimentally proven on-board

techniques for train routing detection on switches based on gyro-odometry and detection of switch

points elements by a laser sensor developed at Czech Railways in the past have been reminded.

Third, it is briefly analysed what would happen if the above described composite LDS architecture

would be also used for Start of Mission with the LDS status UNKNOWN in stand-still. FTA shows

that unavailability of the rail infrastructure sensing function (composed of several techniques) and

external technical and operational provisions (because they can be only applied during train motion)

significantly increases safety integrity demands on GNSS. It is shown how the above findings could

affect the architecture of Cold Movement Detector (CMD), which is the mandatory constituent of the

ERTMS baseline 3.

HELMET- 870257

Page 21 of 86

D3.1 High-Level Design Document

Finally, based on the proposed high-level safety architectures (ARCHITECTURE_1 and

ARCHITECTURE_2) and performed related safety analyses, the RAIL user and system

requirements were converted to the subsystem level.

5.1 RAILWAY PRINCIPLES USED FOR SAFE

ARCHITECTURE DESIGN

Railway safety related systems to be compliant with SIL 3 or SIL 4 must ensure that they will remain

safe in the event of any kind of single random HW fault. This principle is known as fail-safety and

can be achieved by means of the following techniques [3]:

• inherent fail-safety,

• composite fail-safety, or

• reactive fail-safety.

Figure 6. Fail-safe techniques according to CENELEC: (a) composite fail-safety, and (b) reactive fail-safety.

It is evident that implementation of these techniques not only determines which level of safety can

be achieved in the Virtual Balise Reader (VBR) based on GNSS SoL service, but also how efficiently

the GNSS service may be used. The applicability of the individual fail-safety techniques within the

GNSS -based VBR is analysed below.

The inherent fail-safety technique allows a safety-related function to be performed by a single

channel, provided that all the credible failure modes of the channel are not hazardous. It would be

very difficult or impossible to make such evidence in the case of the complex GNSS + VBR, and

therefore inherent fail-safety is not further considered.

The composite fail-safety (Figure 6(a)) allows a safety-related function to be performed by at least

two independent channels. A hazardous fault in one channel shall be detected and negated in

sufficient time to meet the required THR. The fault is detected by the comparison of the output values

of these two or more channels, or also by means of an additional independent diagnosis. This

technique can be applied if two fully equivalent and diverse safety functions exist. Application of this

technique is investigated in case of Track Identification function below.

Finally, the reactive fail-safety (Figure 6(b)) allows a safety-related function to be performed by a

single channel, provided its safe operation is assured by fast detection and negation of any

dangerous fault. For example, legacy SBAS (Satellite Based Augmentation System) or GBAS

(Ground Based Augmentation System) itself can be considered as a system with reactive fail-safety,

HELMET- 870257

Page 22 of 86

D3.1 High-Level Design Document

because the safety function (i.e. position determination) is performed by the GNSS constellation(s)

and its correctness is checked by the SBAS/ GBAS infrastructure.

5.2 ARCHITECTURE_1: REACTIVE FAIL-SAFETY

FOR ALONG TRACK TRAIN POSITION

DETERMINATION

This section deals with the preliminary reactive Location Determination System (LDS) architecture

intended for Virtual Balise (VB) detection, Cold Movement Detection (CMD) and Odometry

Calibration.

Position determination along track is a position estimation problem. In this case, it is possible to

define a FAIL-SAFE STATE when a hazardous failure arises – i.e. train can stop, slow-down, etc.

Therefore, the reduction of Time to Fault Detection and Negation (T

DN

), which correspond to Safe

Down Time (SDT) according to EN 50129 [3], can enable a significant reduction of safety

requirements (i.e. THR increasing) for subsystems such as GNSS and independent diagnosis –

see Figure 6.

In composite solution (Figure 6(a)) the independent diagnosis can be performed by comparing two

full-value diverse safety functions (A and B). In this case it is considered that both Function A and

Function B provide absolutes independent position determination.

Reactive fail-safety in Figure 6(b) is in fact a modification of the composite solution, because an

independent diagnosis (i.e. fault detection) of Function A must be performed. In case of reactive

safety there is only required that the independent diagnosis must detect and negate promptly enough

all failures, which could bring the system into a hazardous state.

The reactive LDS architecture was selected to implement the along track GNSS-based safe

positioning function. The reduction of railway safety requirements for GNSS SoL service, i.e.

exploitation of existing aviation EGNOS SoL service, and use of already available ETCS odometry

(SIL 4 compliant) are the main reasons why the reactive solution is proposed for along track train

position determination. It means that reactive fail-safety is achieved by combination of absolute

position determination (GNSS) and relative positioning (odometry). It is the major difference with

respect to composite fail-safety applied for along track positioning (ATP), which is considered to be

realised by two diverse absolute position determination functions. Since excepting GNSS no other

efficient absolute positioning technology is available, therefore the reactive LDS architecture with a

fail-safe state based on GNSS and odometry was proposed in sections below.

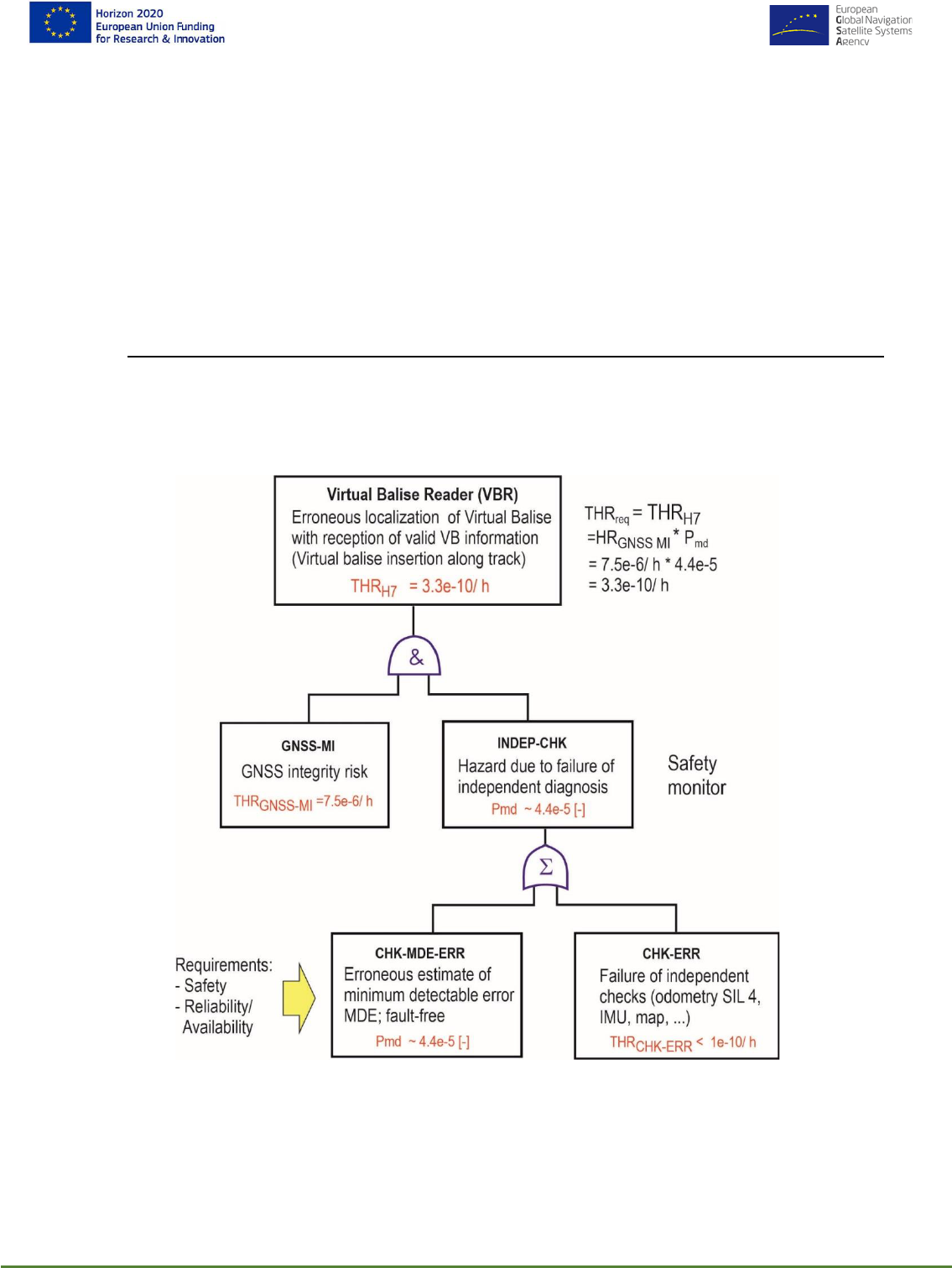

5.2.1 Markov model of reactive LDS

A possible high-level reactive LDS architecture solution (Architecture_1) based on GNSS + AIMN +

ETCS odometry including its Markov model is outlined in Figure 7 [4]. Reactive fail-safety is based

on the principle that the first single failure which could be hazardous, i.e. an excessive along-track

position (ATP) error, either alone or if combined with a second failure, shall be detected and a safe

state of the system enforced (i.e. failure negated) to meet the specified quantified safety target

(THR

H7

of 3.3e-10/h – Virtual Balise insertion along track [2]). Note that THR

H7

is in fact a hazard

related to virtual balise detection, not specifically the output of the LDS for which the hazard is that

HELMET- 870257

Page 23 of 86

D3.1 High-Level Design Document

the ATPL (Along Track Protection Level) does not bound the ATP error. For simplification, however,

THR

H7

is referred to as the safety target in this section.

Figure 7: Reactive LDS safety structure based on HELMET AIMN and independent diagnosis, including Markov model

Time to failure detection and negation (T

DN

), which is a critical parameter of the reactive architecture,

can be derived using the above Markov model – see Figure 7 on the right. T

DN

is also called Safe

Down Time (SDT) according to EN 50129.

The following four system states are defined for the model:

• S

0

: Fully functional LDS state: both ATP (Along Track Positioning) and independent diagnosis

work well according to the specifications. The corresponding probability P

0

(t) represents

probability of correct LDS functioning;

• S

1

: Safe faulty LDS state: ATP is faulty (out if specifications) and rapid diagnosis is functional.

This represents the state of the system prior to T

DN

elapsing. The state is characterised by

the tolerated LDS faulty state probability P

1

(t) that directly depends on T

DN

. Note: If the

faulty sate probability is tolerated, then it means safe (faulty) state;

• S

2

: Fail-safe state of the LDS: ATP fault was detected and negated within T

DN

. The

corresponding probability P

2

(t) represents LDS failure probability in the absorbing state;

• S

3

: Hazardous LDS state, i.e. dangerous undetected failure mode: Independent diagnosis of

ATP did not detect the fault. Note: although LDS can function properly according to the

specifications, the LDS is in a dangerous state. The corresponding probability P

3

(t)

represents probability of dangerous undetected LDS failure in the absorbing state.

A set of first-order differential equations with constant coefficients describing the Markov model in

Figure 7 is following:

= -

HELMET- 870257

Page 24 of 86

D3.1 High-Level Design Document

=

–

(1)

=

=

Boundary conditions are following: P

0

(0)=1, P

1

(0)=0, P

2

(0)=0, P

3

(0)=0 .

5.2.2 Derivation of Time to Fault Detection and Negation

The corresponding time-dependent LDS state probabilities derived from the set of differential

equations (1) are followings:

(2)

(3)

(4)

(5)

Where, HR

GNSS MI

is hazard rate per 1 hour of GNSS+AIMN-based ATP determination, HR

Diag

is

hazard rate of independent GNSS diagnosis, µ is rate of fault detection and negation, i.e. µ

=1/T

DN

=1/SDT.

P

0

(t) represents LDS reliability, i.e. when both GNSS and independent diagnosis are functioning

correctly. It includes only one successful LDS state – S

0

. The other system states (S

1

,

S

2

, S

3

) are

faulty states – safe states (S

1

,

S

2

) or dangerous state (S

3

). State S

3

is the most feared sate, i.e.

dangerous undetected fault.

States S

2

and S

3

are absorbing states. An absorbing state means that model ends in this state. Since

in this reactive LDS architecture we assume that T

DN

is very short (with respect to Mean Time to

Failure (MTTF) of the other channel, i.e. 1/ HR

GNSS MI

), then we can say that S

1

is practically also an

absorbing state, because the P

3

(t) is very low (negligible).

HELMET- 870257

Page 25 of 86

D3.1 High-Level Design Document

Hazard rate of the system (

system

) is generally calculated using failure probability density f(t) and

reliability R(t) as follows:

(6)

However, R(t) is calculated using state probabilities for non-absorbing states. It means that we

cannot calculate R(t) which would also include probabilities for absorbing states S

1

and S

2

.

Therefore, we had to find another solution.

P

1

(t) is the safe faulty state probability of LDS in case of GNSS+AIMN-based ATP fault. Then the

tolerated (expected) probability P

1

(t) for a given value of T

DN

over next interval of 1 hour characterizes

integrity of the safe faulty state S

1

. The expected LDS failure probability P

1

(t) during next 1 hour

interval for T

DN

can be used instead of HR.

Since (HR

GNSS MI

+ HR

Diag

) is much smaller than µ, then equation (3) can be simplified as follows:

(7)

It is evident from equation (7) that P

1

(t) depends on T

DN

(i.e. on 1/ µ) and is no longer dependent on

the time t – see Figure 8. The required THR for LDS during one hour long mission can be expressed

as THR

req

= P1 per 1 hour = HR

GNSS MI

× T

DN

× 1 hour

-1

. Then the T

DN

can be calculated as:

Figure 8: Probability of failure as a function of HR

Non-Train(SIS)

and T

DN

HELMET- 870257

Page 26 of 86

D3.1 High-Level Design Document

Failure of ATP determination (by GNSS) at the LDS system level must not bring the system into a

dangerous state. The safe faulty state (P

1

) of the LDS system in case of ATP failure when the

independent diagnosis is functional has a duration of T

DN

at most because the value of T

DN

is

designed in such a way that the LDS meets the required THR

req

– i.e. THR

H7

of 3.3e-10/h. In other

words, the reactive LDS will be in a safe state although ATP has failed. If ATP failure has not been

detected and negated within T

DN

, then the LDS state is considered as hazardous. An ATP failure

due to GNSS MI cannot be considered as the TPL hazard. It can be only considered as cause of

TPL hazard because the independent diagnostic channel (i.e. Safety Monitor) exists.

The parameters of the diagnostic channel, also called safety monitor, are derived below.

5.2.3 Numerical verification of meaning of LDS state probabilities

Example_1:

Let’s assume HR

GNSS MI

= 7.5e-06/ hour (see §4.1.5 in [2]), HR

Diag

= 1e-10/ hour (example taken for

ETCS odometry), T

DN

= 4.4e-05 h (0.158 s), t=1 hr

Results:

P0 = 0.999992499928126

P1 = 3.299975250851821e-10 …. i.e. THR

H7

of 3.3e-10/h is met

P2 = 7.499641877184870e-06

P3 = 9.999962499759281e-11

Example_2

Let’s assume HR

GNSS MI

= 7.5e-06/ hour, HR

Diag

= 1e-10/ hour, T

DN

= 4.4e-05 h (0.158 s), t=100 hrs

Results:

P0 = 0.999250271187198

P1 = 3.297525896005952e-10 …. i.e. THR

H7

of 3.3e-10/h is met

P2 = 7.497184867985195e-04

P3 = 9.996250887349615e-09

Example_3

Let’s assume HR

GNSS MI

= 7.5e-06/ hour, HR

Diag

= 1e-10/ hour, T

DN

= 2.77e-3 hour (10 s), t=1 hr

Results:

P0 = 0.999992499928126

P1 = 2.083317751586627e-08 …. i.e. THR

H7

is not met for T

DN

= 10 s

P2 = 7.479138697198274e-06

P3 = 9.999962499759281e-11

Conclusions from Examples_1 to 3:

HELMET- 870257

Page 27 of 86

D3.1 High-Level Design Document

• Probability P0 corresponds to reliability. It is evident it is time dependent.

• Probability P1 doesn’t depend on time t. It depends on T

DN

. It is evident that required THR

H7

of 3.3e-10/ h can be met for T

DN

= 4.4e-05 h = 0.158 s (Example_2). If T

DN

is longer, e.g. 10

s (i.e. 2.77e-3 hour), then P1 = 2.083317751586627e-08 over 1 hour interval doesn’t meet

the required THR

H7

of 3.3e-10/ h (Example_3).

• Probabilities P2 and P3 depend on time t (Example_1 and Example_2). It is natural that. But

it doesn’t have a practical relevance. It is because P2 represents a fault probability after fault

was negated – no hazard can happen in the state S

2

. P3 represents dangerous undetected

fault probability of independent diagnosis, which is latent in any case.

5.2.4 Interpretation of T

DN

as P

md

The above described time dependency having impact on resulting THR cannot be directly modelled

by means of an FTA diagram. Therefore, the above reactive technique depicted in Figure 7 can be

redrawn using Fig. 38 in HELMET D2.3 [2] as it is outlined in Figure 9:

Figure 9: Safety monitor in FTA diagram.

The derived Time to Failure Detection and Negation T

DN

can be interpreted in the FTA in Figure 9

via the Probability of Missed Detection (P

md

). Interpretation of T

DN

as P

md

is explained below in §

5.2.8 .

HELMET- 870257

Page 28 of 86

D3.1 High-Level Design Document

5.2.5 Proposed Safety Monitor for run-time safety evaluation

The principle of the safety monitor to be developed for the reactive LDS architecture is outlined in

Figure 10. It evaluates difference in travelled distance measured by GNSS-based LDS and safe

ETCS odometry (SIL 4). If the position error exceeds the Maximum Threshold T

max

(defined by user,

T

max

≥ MDE), then the GNSS ATP failure is detected and negated.

Figure 10: Determination of Minimum Detectable Error (MDE) and maximal decision Threshold T

max

5.2.6 Steps in Safety Monitor design

Design of safety monitor of reactive LDS consists of following steps:

i. Determination of safe down time (T

DN

) using THR

req

and HR

GNSS MI

T

DN

= T

D

(Time to failure Detection) + T

N

(Time to failure Negation);

ii. Determination of missed detection probability (P

md

), which corresponds to the ratio of T

DN

/ 1

hour;

iii. Derivation of probability of false alert P

fa

from the required LDS availability;

iv. Derivation of scaling coefficients K

md

and K

fa

of the safety monitor;

v. Determination of Minimum Detectable Error (MDE) of safety monitor.

HELMET- 870257

Page 29 of 86

D3.1 High-Level Design Document

5.2.7 Example: Derivation of time to failure detection and negation (T

DN

)

Based on Figure 39 in HELMET D2.3 [2], the following assumptions may be made:

• HR

GNSS MI

= 7.5e-6 / hour, which

includes Ground segment fault free system Integrity Risk

(FAULT-FREE), Integrity Risk due to Signal-In-Space Misleading Information (SIS-MI) and

Integrity Risk due to user MI (USER-MI);

• THR

req

=THR

H7

= 3.3e-10 / hour (Virtual Balise insertion along track);

Then time to failure detection and negation T

DN

may be calculated according to:

This gives T

DN

= 3.3e-10 / 7.5e-6 x 1 hour = 4.4e-5 x 1 hour = 0.158 s.

5.2.8 Example: Determination of P

md

for GNSS+AIMN-based ATP failure

Figure 11: Determination of P

md

from duration of GNSS+AIMN-based ATP failure T

DN

Safe down time T

DN

represents the time interval during which the LDS (GNSS+AIMN + independent

diagnosis) is in safe state and also remains safe after output switch was disconnected – see Figure

11 and Figure 7. Since it is assumed that the GNSS+AIMN-based ATP dangerous failure can appear

HELMET- 870257

Page 30 of 86

D3.1 High-Level Design Document

during the next 1 hour time interval with a certain probability, then the T

DN

[hr] relative to 1 hour

represents acceptable Probability of missed detection P

md

, for which the system still remains safe

with regard to the required level THR

req

. The probability P

md

= T

DN

/ 1 hour [-] represents one of the

basic parameters of independent diagnosis, i.e. safety monitor.

P

fa

- is derived from the required LDS availability A defined using unavailability (of ETCS on-board

equipment) U= 1- A= P

fa

. The Gaussian distribution is employed in the safety monitor – see Figure

10. The K

md

and K

fa

coefficients are determined as follows:

5.2.9 Example: MDE determination

Let us assume as an example that LDS unavailability for ERTMS OBU should be U=1e-6, as it is

defined in HELMET D2.3 [2]. Then availability is A= 1-U = 0.999999. If MTTR (Mean Time to Repair)

=1 hour, MDT(Mean Down Time) for ETCS OBU is 1 hour, then MTBF (Mean Time Between

Failures) is about 1e6 hours. Probability of false alert during 1 hour mission is P

fa

= 1/MTBF * 1hour

= 1.0e-6 [-]. Correlation in the monitored travelled distance error is omitted due to diversity between

GNSS and odometry sensors. Further let us assume that P

md

= 4.4e-5 [-] (derived above). Then

• K

fa

(along track) = Norminv (1 - 1.0e-6/2, 0, 1) = 4.8916 ≈ 4.90

• K

md

(along track) = Norminv (1 - 4.4e-5, 0, 1) = 3.9214 ≈3.92

Let’s assume that 1-sigma of position accuracy along track (

ATP

) is about 1.5 m for SBAS and

odometry error is omitted for short travelled distance. Then MDE can be estimated as

MDE = K

fa

x

test|ff

+ K

md

x

test|faulty

MDE ≈ (K

fa

+ K

md

) x

ATP

= (4.90 + 3.92) x 1.5 = 8.82 x 1.5 = 13.23 m ≈ 14 m

Let’s assume that 1-sigma of position accuracy along track (

ATP

) could be about 0.1 m for HELMET

solution supported by AIMN, then

MDE ≈ (K

fa

+ K

md

) x

ATP

= (4.90 + 3.92) x 0.1 = 8.82 x 0.1 = 0.882 m < 1 m

In this case MDE would meet requirement for the location accuracy (of on-board ERTMS Balise

Transmission Module – BTM), which shall be within ±1 m for each (physical) balise, when a balise

has been passed [5]. In this case HELMET solution would meet the requirement for the Odometry

calibration function.

HELMET- 870257

Page 31 of 86

D3.1 High-Level Design Document

Maximal decision threshold T

max

can be set to e.g. 20 m due to operational reasons (to further

improve LDS availability).

5.3 ARCHITECTURE_2: COMPOSITE SAFETY FOR TRACK

IDENTIFICATION

Track discrimination required for ERTMS Start of Mission (SOM) with UNKNOWN status (train

position is not a priory known) is a decision problem. In this case it is not possible to define a FAIL-

SAFE STATE from the system design point of view, which could help to reduce (via fast diagnosis)

safety requirements for subsystems (GNSS and independent diagnosis) and simultaneously meet

required THR (FFR). We cannot say that the determined position of train on one track is safer than

on the other one. A fast diagnosis used in the above Position Estimation Problem is not applicable

for Track Identification / discrimination. It would be wrong to say that fast diagnosis reduces the

system FFR (Functional Failure Rate) in this case. If we would (incorrectly) accept this possibility,

then THR of 3.3e-10/ h required for track discrimination/ identification could be theoretically met (see

HELMET D2.3, §4.1.4, eqn (1) ) by low quality functions A and B (let’s say FR

A

= FR

B

=1e-2/ h) if

SDT would be very short, i.e. 3.3e-6 hour = 0.01188 s - and it is a nonsense.

It is assumed that Track Identification function in LDS status UNKNOWN is performed in Staff

Responsible (SR) mode with a defined low ceiling speed (e.g. v < 30 km/h). It means that safety of

moving train during execution of Track Identification function is under responsibility of driver. If LDS

failure is detected, it means that Track Identification was not successfully completed. Dangerous

undetected failure of Track Identification function has no impact on railway safety in SR mode.

However, this latent LDS failure can have hazardous consequences in subsequent normal train

operation (full supervision of ETCS). Therefore, derivation of (hazardous) Functional Failure Rate

(FFR) of Track Identification function is derived below.

Since fast LDS diagnosis during SR mode has no impact on railway safety, then LDS can be

modelled in a simplified way as a system without failure detection mechanisms. Note: In reality, the

LDS will obviously have a failure detection mechanism to notify that the Track Identification function

has not been successfully completed. The corresponding Markov model of two-channel LDS (two-

out-of-two) performing Track Identification function is shown in Figure 12.

HELMET- 870257

Page 32 of 86

D3.1 High-Level Design Document

Figure 12: Markov model of two- channel LDS (2oo2) without failure detection

The following four system states are defined for the model:

• S

0

: Fully functional LDS state at time t=0;

• S

1

: Element A has a failure - safe faulty state in SR mode;

• S

2

: Element B has a failure - safe faulty state in SR mode;

• S

3

: Both elements have failure Hazardous LDS state – it is dangerous undetected failure

mode. The corresponding probability P

3

(t) represents probability of hazardous latent

failure. This latent failure can endanger railway safety in ETCS full supervision mode.

Solution of liner differential equations of Markov model gives probability P

3

(t) as

Since P

3

(t) corresponds to FFR * t, then for next 1 hour interval one can write

It is evident that realization of the Track Identification function using composite safety requires higher

demands on subsystems (A, B) from viewpoint of safety integrity. For example, the THR requirement

of 3.3e-10/ h for track discrimination function can be met by GNSS position determination as a

Function A with FR

A

of 1e-6/ h and independent diagnosis of GNSS as a Function B with FR

B

of 1e-

4/ h. In this case FFR

Track discrimination

equals to 1e-10/ h.

In case of Along Track Position (ATP) estimation, the THR requirement of 3.3e-10/ h can be met

e.g. by GNSS as a Function A with FR

A

of 1e-4/ h and independent diagnosis of GNSS as a Function

HELMET- 870257

Page 33 of 86

D3.1 High-Level Design Document

B (also absolute position determination) with FR

B

of 5e-3/ h and SDT of 1 s. It can be calculated

using

as stated in [3] and §4.1.4 of HELMET D2.3 [2]. Then FFR

Position estimation

equals to 2.7778e-10/ h.

Duration of track discrimination is limited by operational reasons – i.e. by the average duration of

Start of Mission in Staff Responsible, which is 3% of mission duration (1 hour) according to the

SUBSET-088 [6], i.e. 108 seconds. However, this operational parameter has no impact on safety

integrity of the proposed system architecture.

ETCS onboard subsystem shall take no more than 60 s to go from No Power (NP) to being ready to

accept data entry in Standby (SB) [11]. Therefore, values of 10s < TTA < 30 s proposed by the

HELMET User Requirement UR_001 [1] is appropriate.

5.3.1 Rules for realization of safety related functions with

TFFR < 1e-9/ hour (EN 50129, IEC 61508)

The quantitative safety requirement for Track Identification is expressed through THR

H9

of 3.3e-10/

hour which is related to erroneous reporting of Virtual Balise in a different track – see HELMET D2.3,

Figure 34 [2]. In this development stage, this requirement can be also considered as THR

requirement for across track train position determination function.

According to EN 50129, a safety-related function having quantitative requirements more demanding

(lower) than 1e-9/h shall be treated in one of the following ways:

• if it is possible to divide the function into functionally independent sub-functions, the TFFR

can be apportioned between those sub-functions (allocating TFFR to these functions) and a

SIL allocated to each of them;

• if the function cannot be divided, the measures and methods required for SIL 4 shall, at least,

be fulfilled and the function shall be used in combination with other technical or operational

measures in order to achieve the necessary TFFR.

Similarly, IEC 61508-1 sets a lower limit on the target failure measures for a safety function carried

out by a single E/E/PE safety-related system. For E/E/PE safety-related systems operating in a high

demand or a continuous mode of operation, the lower limit is set at an average frequency of a

dangerous failure of 1e-9/ hour.

Conclusion: Track Identification function for ERTMS with based on GNSS must not be realised as a

single function.

5.3.2 AND-combination logic

Railway functional safety is strictly based on logical AND-combination approach, i.e. failure of

functions shall be independent with respect to systematic and random faults. Independence among

functions, from common random causes (CCF) and common systematic causes is required.

HELMET- 870257

Page 34 of 86

D3.1 High-Level Design Document

When a hazard results from the failure of two or more independent functions (i.e. logical AND combinations),

the following rules shall be applied (EN 50129 [3]):

• Freedom from common random and systematic causes shall be demonstrated by CCF analysis;

• Each function shall be able to prevent the hazard. Therefore, a failure of one of the independent

functions shall not lead to the hazard (i.e. fail-safe approach must be implemented);

• The functions shall be diverse (i.e. use different functional approaches or technology) so as to avoid

common causes leading to the hazard;

• Safety integrity of each independent function shall not rely on the results (e.g. outputs) of the other

independent function(s).

• A fault in any function shall be detected and a safe state enforced within a time compatible with the

THR/TFFR of higher level hazard or function. This detection should be provided by a means

independent of the function under consideration.

Note: In case of Track Identification function (LDS status UNKNOWN), time to failure detection and negation

T

DN

doesn’t impact safety integrity of LDS. Track Identification is a decision problem without a priory defined

a fail-safe state (track number). Track Identification (LDS status UNKNOWN) is being performed in Staff

Responsible (SR) mode with low ceiling speed (v< 30 km/hr), so railway safety in this mode is under train

driver’s responsibility.

5.3.3 High-level composite LDS architecture for Track Identification

based on track-side data

In this section there is proposed LDS architecture with composite safety (ARCHITECTURE_2) that

profits from competitive technical and operational data (including relevant meta data) provided by

the railway track-side infrastructure and Traffic Control Centre. The safety-related track-side data

and relevant meta-data are aggregated for a pre-set train route before Movement Authority is granted

to the train driver. The on-board LDS sensor data are then AND-combined with the diverse track-

side data (and meta-data) in order to improve LDS safety integrity. In addition to Track Identification,

this architecture is also intended for along track position determination. The proposed composite

LDS architecture is outlined in Figure 13.

HELMET- 870257

Page 35 of 86

D3.1 High-Level Design Document

Figure 13: Principal composite safety LDS architecture intended for Track Identification function

In contrast to road transport, railway vehicles cannot arbitrarily move on the railway infrastructure. A

Movement Authority must be granted to a specific train / driver. Before the MA is sent to the train, it

must be known where the train has to go (track number, location) and which route the train will run

on. It is evident that the operational information rated to MA and technical information regarding train

route setting could be utilized for LDS safety improvement. It means that in addition to functional

safety principles (used for GNSS-based LDS) also other safety provisions such as Technical

measures or Operational measures can significantly improve safety integrity of train position

determination function, if they could be logically combined via AND operator – see Figure 14.

HELMET- 870257

Page 36 of 86

D3.1 High-Level Design Document

Figure 14: FTA of the LDS with composite safety: technical and operational safety measures have been introduced to

meet the required THR < 1e-9/ hr for main LDS hazard.

In addition of train position determination using GNSS + ARAIM, movement of train on the railway

infrastructure could be determined via on-board environment sensing techniques such as gyro-

odometry, computer vision, detection of rail switch elements (e.g. guard-rail), etc.

Further, diagnostic data coming from railway infrastructure (e.g. switch position monitored via switch

position sensor device) supporting LDS integrity enhancement can be used as Technical safety

measures. And finally the information regarding MA provided by a Traffic Control Centre could be

utilized as Operational safety measures – see Figure 15.

HELMET- 870257

Page 37 of 86

D3.1 High-Level Design Document

Figure 15: FTA of LDS with applied specific technical and operational safety measures. Examples of minimum THR/TFFR

requirements for individual functions in the composite solution are marked in red)

HELMET- 870257

Page 38 of 86

D3.1 High-Level Design Document

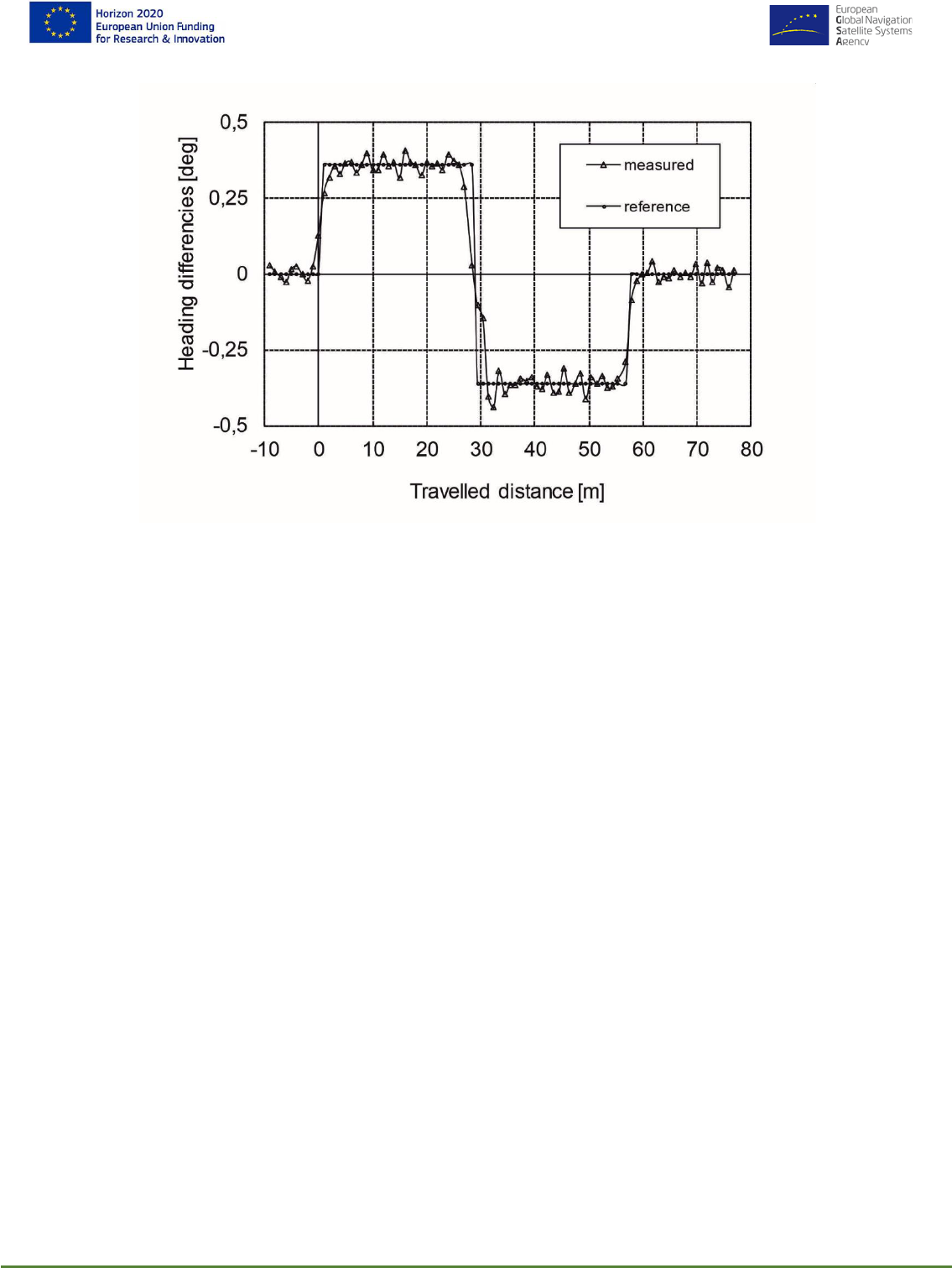

5.3.4 Rail track-side infrastructure sensing