An Overview of Complex Drug Substances and

Complex Formulations-A Quality Perspective

Katherine Tyner, PhD

Associate Director for Science (Acting)

Office of Pharmaceutical Quality

Center for Drug Evaluation and Research

U.S. Food and Drug Administration

2

Disclaimer

This talk reflects the views of the author and should not

be construed to represent FDA’s views or policies. The

mention of commercial products, their sources, or their

use in connection with material reported herein is not to

be construed as either an actual or implied endorsement

of such products by the Department of Health and

Human Services.

3

Outline

• Background to Complex Products and Quality

• Quality Considerations for Complex Drug Substances

• Quality Considerations for Complex Formulations

• Analytical and Emerging Technologies

• Helpful Tips

4

Complex Generics

As part of the FDA’s efforts to promote drug competition and patient access, we’ve

advanced many policies aimed at making it more efficient to bring generic competition to

the market. We’ve been especially focused on a category of medicines known as complex

drugs. These are drugs that, by nature of their formulation, delivery systems or the

complexity of their active ingredients, for example, are harder to “genericize” under

traditional approaches. As a result, these complex drugs often face less competition.

- Dr. Scott Gottlieb

5

Complex Products

COMPLEX of: Complex Product Type Drug Products

Active Pharmaceutical

Ingredients (APIs)

peptides, complex mixtures of APIs,

naturally sourced ingredients

Glatiramer acetate injection, Sevelamer

carbonate tablet/powder, Conjugated

Estrogens tablet

Formulations/Dosage

Forms

liposomes, colloids, transdermals,

extended-release injectables, implantables

Doxorubicin HCl Liposome injection,

Cyclosporin ophthalmic emulsion,

Etonogestrel implant, Lidocaine patch

Routes of Delivery locally acting drugs such as dermatological

products, complex ophthalmological

products

Acyclovir topical cream/ointment,

Prednisolone acetate ophthalmic suspension

Drug-Device

Combinations

dry powder inhalers, metered dose inhalers,

nasal sprays, auto-injectors

Mometasone furoate nasal spray, Fluticasone

propionate and Salmeterol inhalation powder,

Epinephrine auto-injector

Other products

complexity or uncertainty concerning the

approval pathway or possible alternative

approach would benefit from early scientific

engagement

Abuse deterrent opioid formulations

https://www.fda.gov/downloads/ForIndustry/UserFees/GenericDrugUserFees/UCM525234.pdf

Generic Drug User Fee Amendments (GDUFA) II Commitment Letter:

6

Complex Generics

Our aim is to enhance transparency, provide greater clarity and scientific guidance for

generic drug developers, and support the availability of high-quality, safe and effective

generic medicines.

- Dr. Scott Gottlieb

7

Pharmaceutical quality is

consistently meeting standards

that ensure every dose is safe

andeffective, free of

contamination and defects.

8

Quality Is a Shared Responsibility

• FDA’s Goal: Ensure industry can manufacture

products that consistently safely deliver their

intended benefit to the patient.

• Industry: Understand and manage their

manufacturing processes and expand the

product/process body of knowledge to facilitate

continual improvement (ICH Q10).

www.fda.gov

9

A Generic Drug Submitted to FDA for Approval

Must Demonstrate:

• The generic drug is “pharmaceutically equivalent” to the brand

• The manufacturer is capable of making the drug correctly

• The manufacturer is capable of making the drug consistently

• The “active ingredient” is the same as that of the brand

• The right amount of the active ingredient gets to the place in the body where it has

effect

• The "inactive" ingredients of the drug are safe

• The drug does not break down over time

• The container in which the drug will be shipped and sold is appropriate.

• The label is the same as the brand-name drug’s label

• Relevant patents or legal exclusivities are expired

https://www.fda.gov/downloads/Drugs/ResourcesForYou/Consumers/BuyingUsingMedicineSafely/GenericDrugs/UCM510852.pdf

10

Complex Drug Products

• Present challenges for demonstrating product

equivalence

• Present challenges for demonstrating product

and process control

www.fda.gov

11

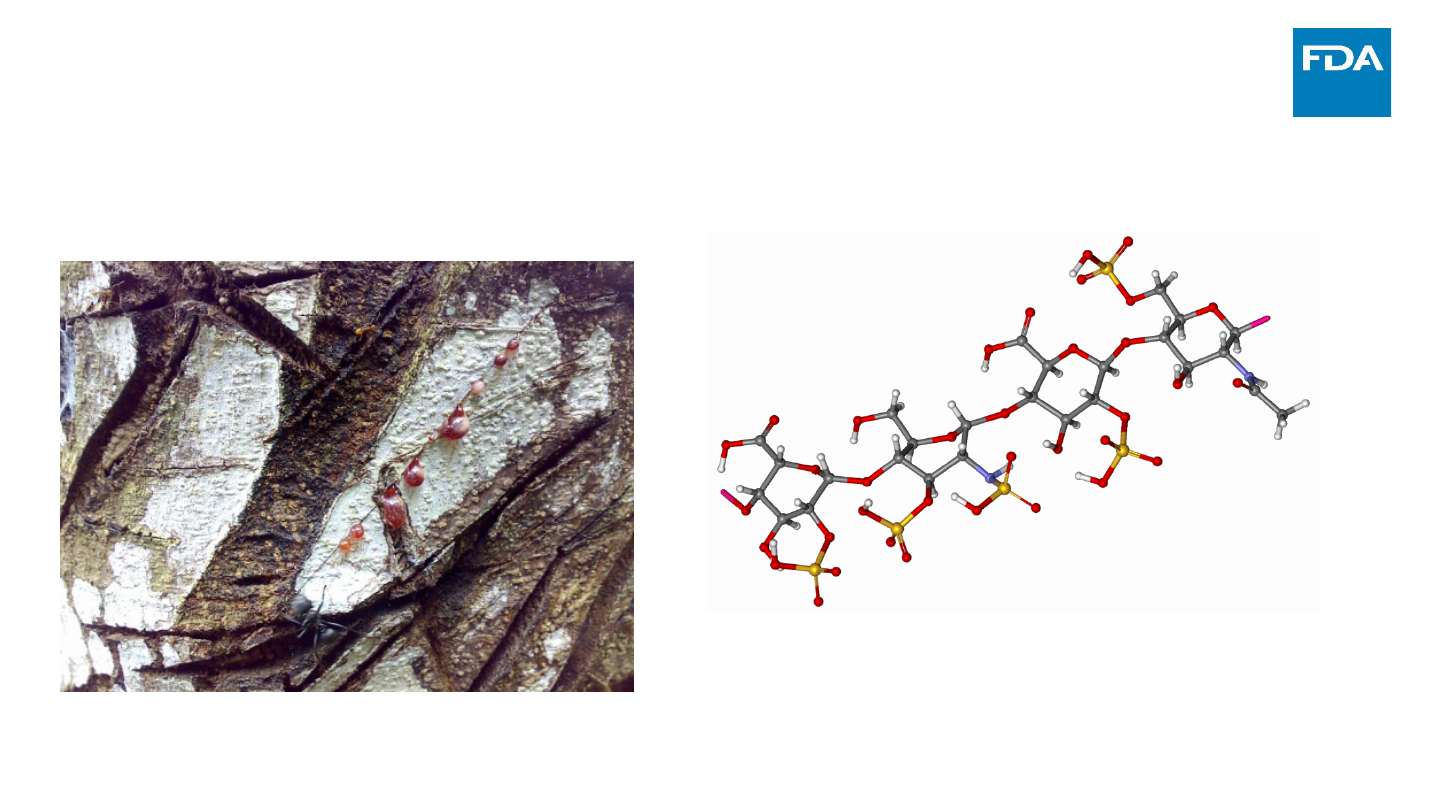

Quality Considerations for Complex

Drug Substances

https://en.wikipedia.org/wiki/Crofelemer#/media/File:Sangre_de_Grado.jpg

https://en.wikipedia.org/wiki/Enoxaparin_sodium#/media/File:Enoxaparin

_sodium_ball-and-stick.png

12

Complex Active Ingredients

• Sameness of the active ingredient typically determined

via four elements:

– Fundamental manufacturing scheme

– Physicochemical properties

– Structural signatures

– Confirmatory assays

• Examples

– Complex mixtures of APIs

– Naturally sourced ingredients

Slide Credit:

Andre Raw

Slide Credit:

Andre Raw

16

Quality Considerations for Complex

Formulations

17

Complex Formulations

• Sameness of the formulation structure is typically

determined via

– Physicochemical measurements

– In vitro assay (e.g. release or absorption)

• Examples

– Liposomes

– Ophthalmic emulsions

18

Case Study—Complex Formulation

• Liposome: microvesicle composed of a bilayer and/or

a concentric series of multiple bilayers separated by

aqueous compartments formed by amphipathic

molecules such as phospholipids that enclose a

central aqueous compartment

• Liposome Drug Product: a drug product in which the

active pharmaceutical ingredient (API) is contained

in liposomes

• There are 12 FDA approved drug products containing

liposomes

– Commonly used to alter the biodistribution of an API

Draft Guidance for Industry. Liposome drug products, chemistry, manufacturing, and controls; human pharmacokinetics and bioavailability; and labeling documentation. U.S. Food and

Drug Administration.

http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm070570.pdf (2015)

www.fda.gov

19

Liposome Drug Products are Complex Formulations

• Components of the liposome

– Lipids

– Other excipients

• Physical and chemical stability

– Chemical degradation of lipids may form

lysolipids

– Liposome fusion

• In vitro release

– Discriminate between acceptable and non-

acceptable batches of the drug product

• Complex physicochemical testing

R

1

R

2

R

3

20

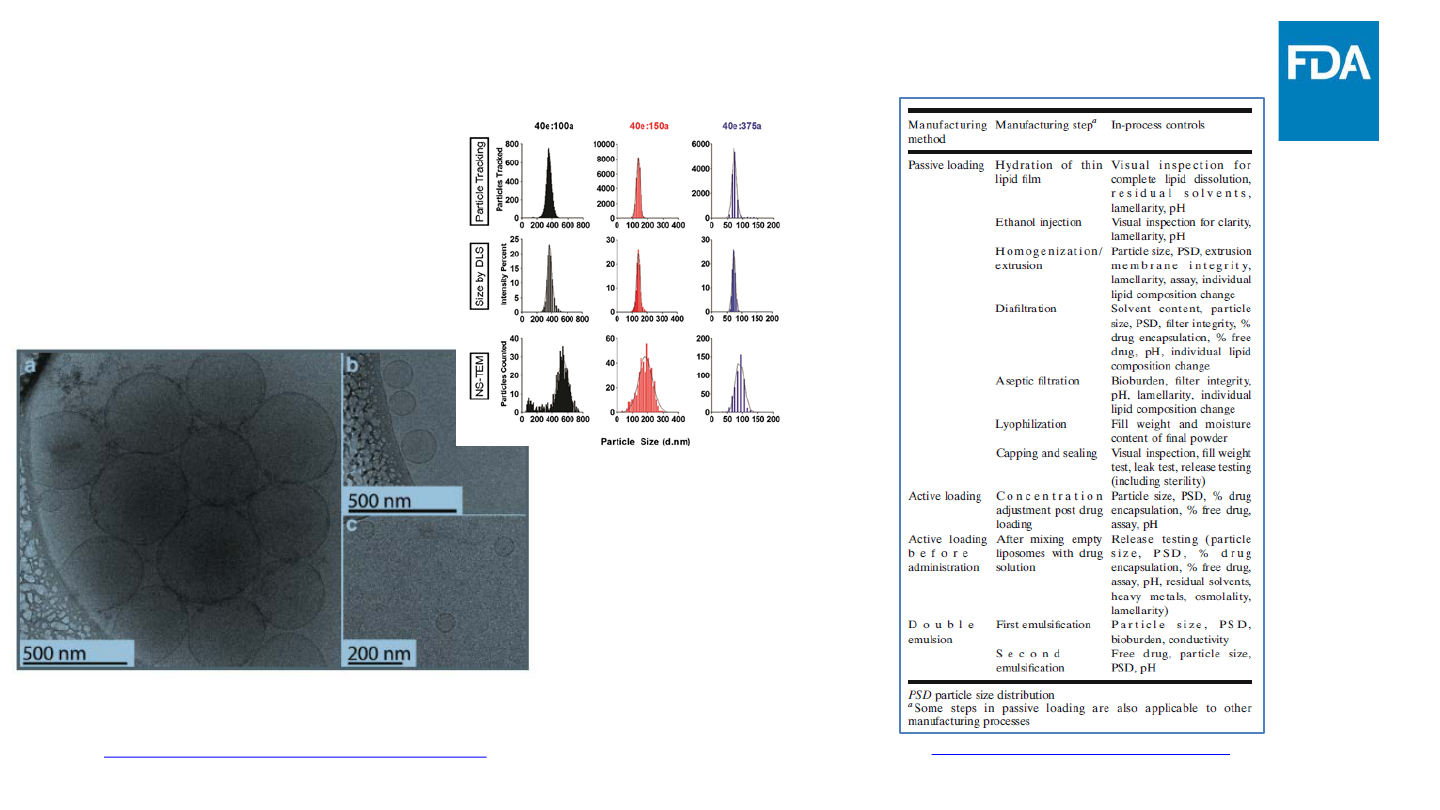

Liposome Drug Products Involve Complex

Physicochemical Testing

• Suitable analytical methods need be employed to properly

characterize liposome drug products, which can often be

difficult given the complexity of liposome drug product

formulations

• Use of inappropriate methods could produce false results,

thereby calling into question data reliability and, hence,

product quality

• Particle size is a critical quality attribute for liposome drug

products

– Impacts ADME, stability, drug release, etc.

– Multiple techniques, such as dynamic light scattering (DLS) and

electron microscopy (EM), are usually recommended to

thoroughly characterize particle size and size distribution

• Size is not the only attribute that needs to be characterized

– Morphology, drug loading, drug leakage etc.

www.fda.gov

21

Summary of Quality Issues for Liposome Drug Products

Kapoor M. et al. AAPS J 19(3) 2017

Challenges

(1) Identification and appropriate characterization of critical quality attributes

(2) Suitable control strategies

23

Analytical and Emerging Technology

Mass Spec

Dissolution

NMR

SEM

Gas Chromatography

High Performance

Liquid Chromatography

XRPD

Particle Sizing

Compression

Machine

Continuous

Manufacturing

3D

Printing

Slide Credit:

OTR

24

Analytical and Emerging Technology

• The properties, characterization, and methods of characterization may be different

than what is typical for other drug products

• These challenges do not reduce the adequacy and standard requirements of the

analytical methods

– Guidance for Industry: Analytical Procedures and Methods Validation for Drugs and Biologics

• Instrumentation and methodology for characterization of complex drug products is an

evolving area

– Appropriate validation and justification of the method is critical

• It is often necessary to utilize multiple complementary or orthogonal techniques

– Different methods can provide various key aspects of an attribute and thus provide a more

complete characterization picture of the drug product

25

Analytical and Emerging Technology

• Challenging vs impossible

• Difficult vs infeasible

• Rapid advancements in

analytical techniques foster

the development of complex

products

Picture Credit: Xiaoming Xu and Erin Wood

26

Helpful Tips

27

Consensus-Based Standards

• Development of technical voluntary consensus standards

– Performance characteristics of dosage forms

– Testing methodologies

– Scientific protocols

• CDER participates in committees of several standards setting

organizations

– ASTM International

– International Organization for Standardization

• CDER Standards Recognition Program

– https://www.fda.gov/ucm/groups/fdagov-public/@fdagov-drugs-

gen/documents/document/ucm631269.pdf

27

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM386366.pd

29

Emerging Technology Program

29

• Supports industry’s development and

implementation of innovative approaches in

pharmaceutical design and manufacturing

• Identifies and resolves potential scientific and

policy issues related to new approaches

– Enabled the approval of the first switch from

batch to continuous manufacturing (CM) process

for an approved drug

• A website and Guidance for Industry are

posted

30

Take-Aways

• There are many forms of complexity within drug products

• Complexity in drug products can translate to complexity in identifying,

establishing, and maintaining quality

• A suite of analytical techniques is often needed in order to adequately

demonstrate product quality

• There are multiple ways to interact with FDA during the development

of complex products

www.fda.gov