VISION 3

Intelligent design, operation and

analysis for eld-ow fractionation

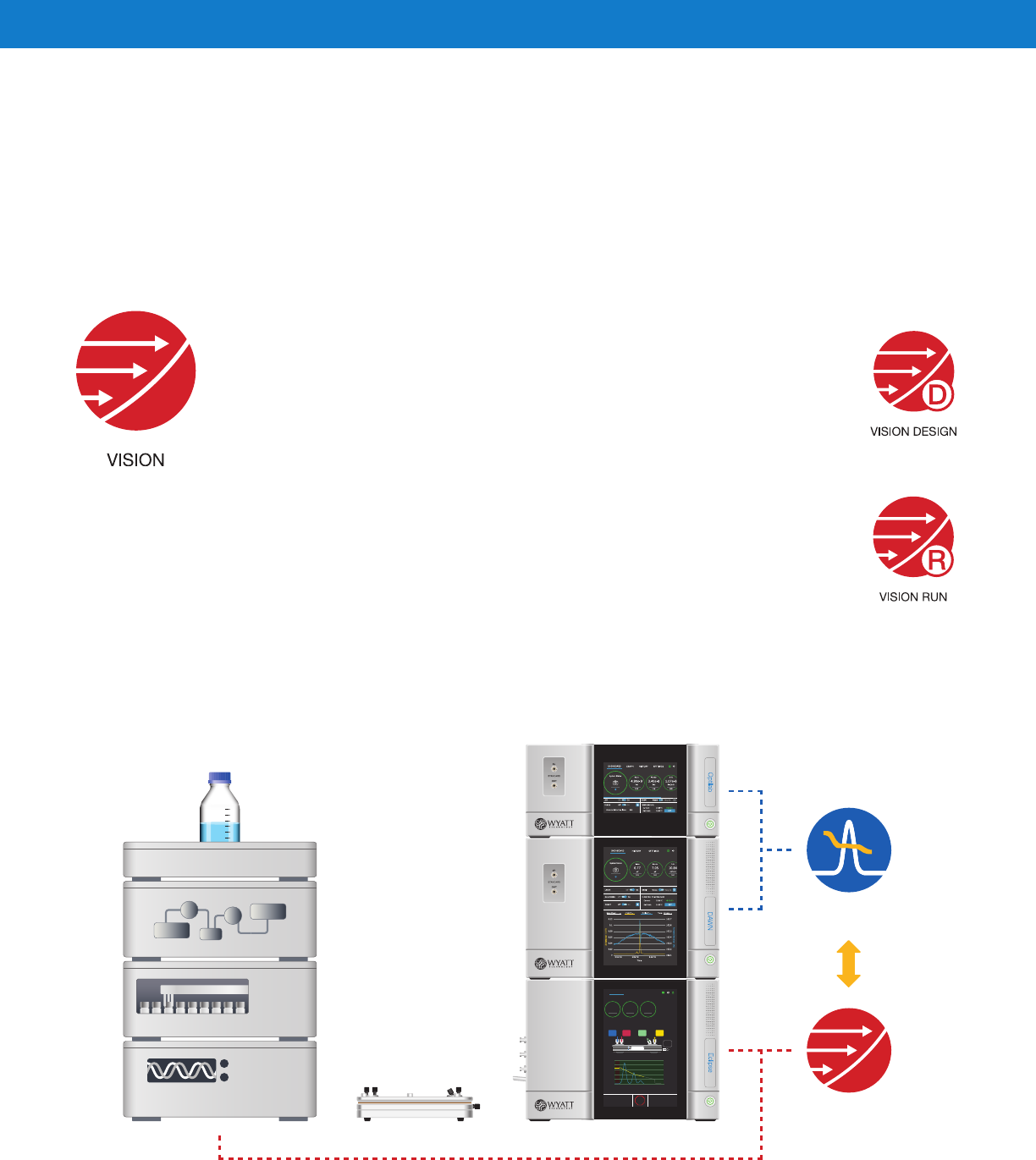

VISION

TM

Look ahead, see more

VISION, the brains behind FFF

FFF-MALS—eld-ow

fractionation with online

multi-angle light scattering

detection—is a powerful tool

for characterizing all types of

macromolecules and nanoparticles in solu-

tion or suspension. VISION software is the

intelligent human interface to an FFF-MALS

system built on Wyatt Technology’s Eclipse

™

FFF controller and DAWN

®

MALS instrument.

VISION comprises two

primary modules:

VISION DESIGN

™

carries out physics-

based FFF simulations for in silico

method design and optimization.

The physics engine also calculates

diusion coecients and zeta

potential from FFF and EAF4 measurements.

VISION RUN

™

is comprehensive

software for running FFF methods.

It seamlessly coordinates the pump

and autosampler front-end with the

Eclipse, detectors and ASTRA

®

,

and records FFF, electrical and UV signals for

diagnostics and analysis in VISION DESIGN.

VISION interfaces with ASTRA, the industry-leading light scattering analysis software for

determination of molar mass, size, conformation, composition, particle concentration and more.

ASTRA

VISION

Channel Pressure

Cross Flow Pressure

Inlet Pressure

8.86 bar

11.88 bar

15.12 bar

DCM Pressure 0.54 bar

Current

Voltage

pH

-6.0 V

-1.0 mA

8.0

Conductivity 0.011 S/m

Stop

Flow

Channel Status (mL/min)

1.15 0.00 0.80 0.20

Inlet Inject DCM Outlet

FFF Method

0.15

Cross

-1.0 mA

0

0.01

0.02

0.03

0.04

0

0.1

0.2

0.3

0.4

0.5

0 10 20 30

UV A Signal (AU)

Cross Flow (mL/min)

Time (min)

DASHBOARD HISTORY SETTINGS

Noise Wander Dri

LowLowLow

µAU/minµAUµAU

0.040.280.24

Inj: 25

2

3

Integrated Workflow

From method development to nal results

VISION oers a seamless workow in a few simple steps, starting with developing and optimizing the ow program

in silico, then running a sample sequence, followed by data processing, rening the separation method, reporting

and consolidating the data les in projects.

DESIGN METHOD

• Estimate particle size in sample

• Select spacers and flow profiles

• Use FFF theory to simulate

and predict separation

RUN EXPERIMENTS

• Acquire flow, electrical and

UV data

• Collect fractions

• Monitor and diagnose system

Transfer optimized method

Launch and synchronize ASTRA

• Collate project files

• Estimate particle size from

retention time

• Refine method

• Determine zeta potential

ANALYZE AND REPORT

• Basic and advanced MALS-

DLS-UV-RI characterization

• EASI Graph overlays

• EASI Table consolidated results

• Customized reports

FFF Method Development

Let your PC do the work

Have a new sample to analyze? VISION

DESIGN eliminates the need to spend

inordinate amounts of time running

a matrix of experiments to develop an

FFF method. Just list the estimated

particle sizes, select your FFF channel,

membrane and spacer, and specify

a cross-ow gradient.

VISION DESIGN immediately displays the

predicted fractogram using fundamental

FFF theory to calculate retention times.

It only takes a few minutes to explore

the eect of dierent cross ow rates and

timings to improve resolution and nd

the best method - all from the comfort

of your desk.

Rene the method

The nal design can be transferred in a

click to VISION RUN to test your method.

Your initial guess of sample and

channel parameters may have been

inaccurate, but have no concern —

results of a physical experiment can be

fed back into VISION DESIGN to further

rene the method. Usually a single test

run suces to give VISION DESIGN

the information it needs to help you

fully optimize your method.

4

5

Enter the cockpit

VISION RUN is a sophisticated control center for the

Eclipse FFF system. The dashboard shows the system

status in real time with direct access to instrument

congurations and sample sequences. Status

information from the Eclipse instrument’s Health

Indicators are displayed; should any warnings come

up, you will receive actionable recommendations.

Expand your horizons

VISION RUN uses the ICF instrument control

framework for Agilent

®

modules from the 1260

series. The complete feature sets of autosamplers,

isocratic or quaternary pumps, diode array

detectors, uorescence detectors and fraction

collectors are supported to extract the maximum

from FFF experiments.

FFF Instrument Control

Fly on autopilot

Once your sample sequence table is dened in

VISION RUN, including FFF operation and MALS

analysis methods, it’s time to take ight. Sit back and

trust VISION to run on autopilot, orchestrating the

entire FFF-MALS measurement.

Should the need arise, system health indicators

will alert you to intervene and prevent wasted runs.

Decided to add more samples to a running sequence?

Simply create another line in the table and VISION RUN

will incorporate the additional samples.

Automated Sample Sequences

• Administrator, researcher, technician

and guest access levels

• Full audit trails

• Secure, joint SQL database

for VISION and ASTRA data

• Local or remote database connectivity

• Data integrity validation

• Full IQ/OQ procedures

and documentation validation

Regulatory Compliance

VISION oers an optional 21 CFR Part 11 compliance package, including IQ/OQ documents and procedures.

6

7

Distributions and moments,

percent aggregation

Molar Mass and Size

Absorption Correction

Glycoproteins, pegylated proteins,

membrane proteins,

protein-nucleic acid complexes

Protein Conjugation

Branching ratio and

number of branches

Polymer Branching

Custom Plots

From RI concentration

UV Extinction

Coefficient

MALS and chromatography

quality assessment

Diagnostics

Plate count, resolution,

asymmetry, tailing

Peak Statistics

Column calibration,

universal calibration

Traditional SEC

Correct for non-linear baseline changes

Baseline Subtraction

rms radius, sphere radius,

rod length, hydrodynamic radius

Particle Size

Total number of particles

Particle Concentration

Radius or intrinsic viscosity

vs. molar mass

Conformation

Total viral titer,

empty:full ratio (C

p

/V

g

)

Viral Vector

Refractive Index Increments

Particle Shape

Copolymer Analysis

Results Fitting

M

a

c

r

o

m

o

l

e

c

u

l

e

s

A

d

v

a

n

c

e

d

A

n

a

l

y

s

i

s

N

a

n

o

p

a

r

t

i

c

l

e

s

C

h

r

o

m

a

t

o

g

r

a

p

h

y

ASTRA

Comprehensive characterization of FFF-MALS data

Building on over 40 years of light scattering research and development, ASTRA includes

an unrivaled range of analysis features to characterize macromolecules and nanoparticles.

Learn more about ASTRA’s capabilities at www.wyatt.com/astra-benets

FFF Data Analysis

Particle size distributions

Even without light scattering, VISION

DESIGN can read in FFF data collected

by VISION RUN to determine the hydro-

dynamic radius (R

h

) and its distribution in

the sample based on FFF retention time.

Choose from a calculation based on

fundamental FFF theory or calibration

with reference standards. The detailed,

high-resolution R

h

distribution comple-

ments FFF-MALS, batch dynamic light

scattering (DLS) and nanoparticle tracking

analysis (NTA).

Electrophoretic mobility

and zeta potential

VISION calculates zeta potential and

electrophoretic mobility from EAF4

measurements made with dierent

applied electric elds. Data treatment

is fully automated, including baseline

and peak selection plus determination

of peak retention time and its shift with

the electrical eld.

VISION compares hydrodynamic radius distributions from FFF theory (red)

with geometric radius distributions from MALS (green).

8

6330 Hollister Avenue | Santa Barbara, CA 93117 | Tel: +1 (805) 681-9009 | Email: [email protected]

Left to Right

Geofrey K. Wyatt, Chief Executive Ocer

Dr. Philip J. Wyatt, Chairman of the Board

Cliord D. Wyatt, President

Wyatt Technology provides

absolute macromolecular and

nanoparticle characterization

solutions by developing the nest

instrumentation and services

to chemical, petrochemical,

pharmaceutical, biotechnological

and academic laboratories

worldwide. We delight our

customers with unparalleled levels

of service and support, facilitating

their cutting-edge research and

development eorts.

VISION is one of many tools in

Wyatt’s Light Scattering Toolkit used

to characterize proteins, polymers

and nanoparticles in solution.

Learn more at www.wyatt.com

Project and Data

Management

Copyright ©2021, Wyatt Technology Corporation. All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted, in any form by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of Wyatt Technology Corporation.

One or more of Wyatt Technology Corporation’s trademarks or service marks may appear in this

publication. For a list of Wyatt Technology Corporation’s trademarks and service marks, please see

https://www.wyatt.com/about/trademarks.

© Wyatt Technology | W2000D

Learn more about FFF-MALS: www.wyatt.com/f-mals

System data traces

An invaluable function of VISION

DESIGN is the overlay of system

data traces for experiments within a

sequence or project. Deviations in

ow rate, pressure, or any other data

trace are readily identied to validate

results and facilitate troubleshooting.

Smart project

administration

VISION organizes all FFF and MALS

data as projects, for convenient

review and replication, as well as

comparison and reporting. Projects

can be merged and experiments

added or deleted at will, making

this a powerful and exible way to

handle large sets of FFF experiments.