Steam Turbine Seminar -17

Lund University

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 2

Something on hydraulics…

N.B. This is an old setup with 1 of 2 – the state-

of-the-art is 2 out of 3 trip redundancy (both the

protection system and the hydraulics)

• The safety system works like a three-way

valve

• The trip system will simply de-pressurize the

hydraulics system

• Most “direct” trips such as speed and

condenser pressure have been replaced by

2/3 measuring devices (and trips)

• The 2/3 philosophy makes it possible to

“test” the trip all the way to the hydraulics

• ESV movability test

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 3

Trip logic – non exhaustive principle

Lube oil pres

≥2

≥2

≥2

≥2

Vibrations

≥2

≥2

≥2

≥2

≥2

N.N.

≥1

High exh temp

≥1

≥1

2oo3

1oo2

≥1

≥1

≥1

High brg temp

PLC

Bus

≥1

≥1

≥1

N.N.

Speed < max

Speed < max

Trip block 2oo3

Hard-wired

Speed < max

P

cond

< max

P

cond

<max

P

cond

< max

Ch.1

Ch.2

Ch.3

≥1

≥1

≥1

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 4

Trip block – two out of three logic

Manual

trip valve

Pressure

switch

PI

ESV

Hydraulic

supply unit

Channel A Channel B Channel C

) (

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 5

Trip block – test

Pressure

switch

PI

ESV

Manual

trip valve

Hydraulic

supply unit

Tripped channel

) (

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 6

Trip block – trip

Pressure

switch

PI

ESV

Manual

trip valve

Hydraulic

supply unit

Tripped channel

Tripped channel

No pressure!

) (

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 7

The ”Duck-Curve”…

4.3 GW/h

California

Sweden

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 8

Flexibility

Start

Steady state

Active generation

control

Spinning reserve

off-peak

turndown

SS

Shutdown

Load

LF

Load

Courtesy of Siemens

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 9

Start-up transient stress

Courtesy of John Gülen, “Gas Turbine Combined Cycle Fast Start: The Physics Behind the Concept”

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 10

Turbine pressures vs. flow (load)

CondSteamSteam

outCW,inCW,CWp,CW

hhmQ

TTcmQ

LMTDAUQ

SteamSteam

mh

SteamCondCond

mmh

CWp,CW

c,m

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Normalisedpressure[‐]

Normalisedflow[‐]

Linear CV

Extr#5 Extr#4

Extr#3 Extr#2

Extr#1 Cond

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 11

0

2

4

6

8

10

12

14

16

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Condenserpressure

Linear

Extraction#1pressure

Pressureratio

Condenser pressure vs. flow (load)

Relative flow [-]

Relative pressure [-]

Section pressure ratio[-]

Turbine load

CondSteamSteam

outCW,inCW,CWp,CW

hhmQ

TTcmQ

LMTDAUQ

SteamSteam

mh

SteamCondCond

mmh

CWp,CW

c,m

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 12

The proof…

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 13

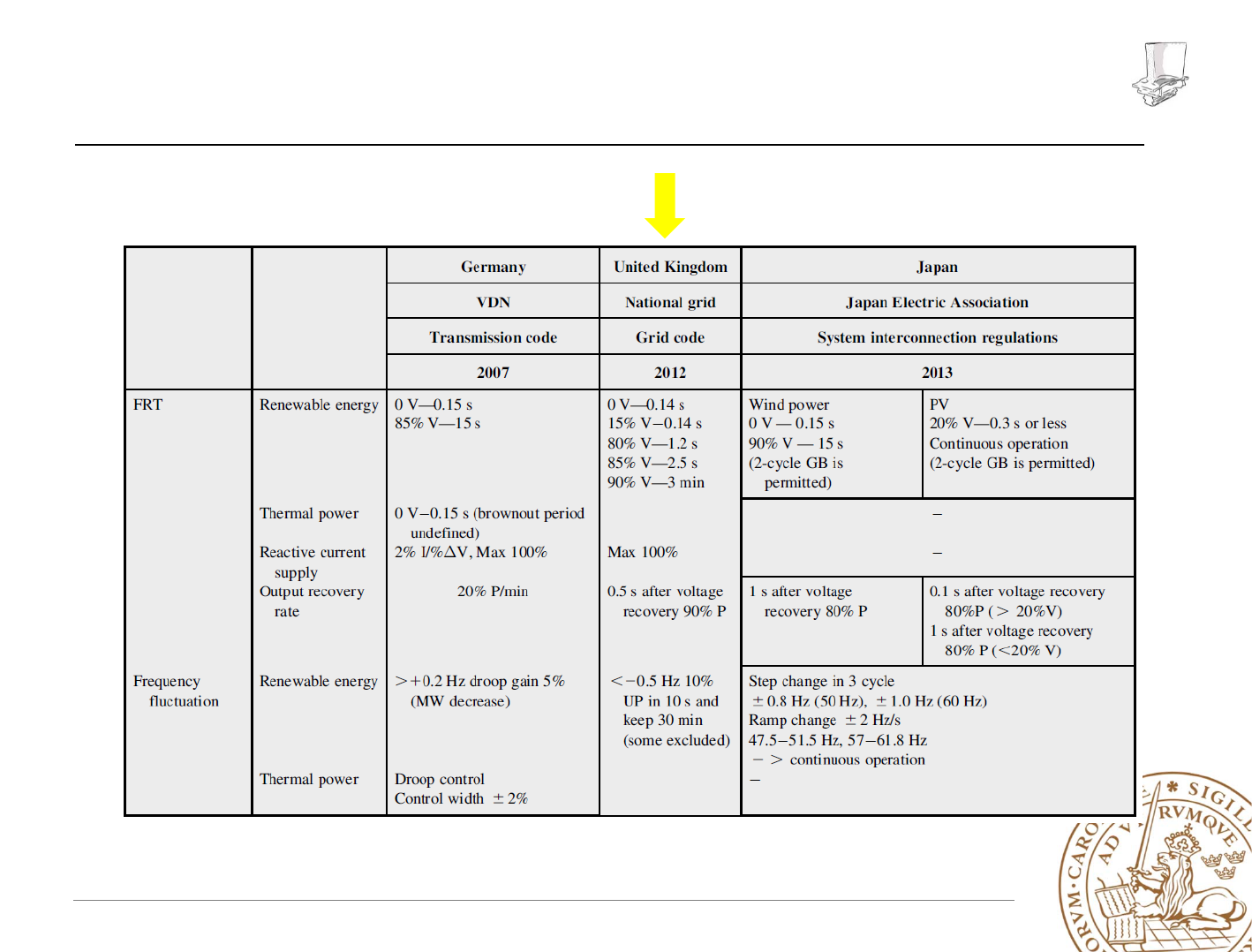

Grid codes

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 14

Grid stability

12

⁄

·

·

1 2

⁄

· 2··

·

⁄

The inertia constant:

The inertia constant is typically within the range of 5 and 10 seconds:

Nominal power = 500 MW

5 s. 2500 MJ

10 s. 5000 MJ

5000

48

·

1

0.4

260

Energy required during a start @ 5000 MJ, as 48 MJ/kg natural gas:

This is equivalent of some 280000 cups of tea!

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 15

Grid stability

1 2

10

9876543

Grid demand (4500 MW)

10 units á 500 MW running at 90 % load – 4500 MW

∆

·

·

0.00

10.00

20.00

30.00

40.00

50.00

60.00

0 20406080100120

Frequency

Time

Speed/frequency vs. time @tau=10 s.

@

∆

2·

·

·

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 16

Grid stability

@

∆

2·

·

·

∆

100

·

·

·

·

1

2··

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 17

Increased flexibility – starting

• Stress controller

– State-of-the

• Blankets

– Since the 80s – mature if OEM involved

• Hot air

– High initial cost

– Very effective

• High-speed barring

– Risky…

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 18

Heating blankets

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 19

Hot-air ST warming

Hot air

• Used by Karlshamnsverket (KKAB) since 1980s

Large 340MW HP-IP-LP Alstom (BBC) utility turbines

• Flanges for blower/heater

• Open vacuum breaker

About 15 minutes for hogging/vacuum pull

No corrosion risk since RH<<60 percent

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 20

Background

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 21

High-speed barring

• Both ventilation and disk friction feed energy into the

trapped steam.

– Scales with speed cubed and density

– Normal barring speed is approx. 200 rpm

• Potential risk of uneven temperature

– More work with longer blades and stage diameter

– LSB spray cooling

– Pipe and valve from HP-extraction to condenser

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 22

Shaft glands

Courtesy to Siemens

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 23

Gland system – Increased pressure

No or low load

FAN

Low P. Low P.

Spray

Sep.

1.1...1.3 bar(a)

0.98 bar(a)

Controlling

Closed

• The mass flow of seal steam

into the turbine(s) follow a

Fanno line

• Steaming seals should be

avoided

• Steam into the HPT through

seal off-load pipe(s)

• Steam supply must be

available

• No hard-ware modifications

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 24

Increased flexibility – in operation

• Capacity bypass

– Loss one in use

• Extra arc

– Small loss when not used

• Top-heater shut-down

– Thrust force

• Condensate pump shut-down – sliding pressure mode

– Caveat! Drum- and hot well levels

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 25

Enhanced flexibility

HP

LP

G

FWT/DEAE

Capacity by-pass

HP-FV by-pass

• HP-FWH bypass

• Capacity bypass

• Top-heater for

constant FW-temp

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 26

Rotor stress – temperature gradients

T

r

T

Center

T

Average

T

Steam

T

Surface

ΔT

y

ii

r

r

r

r

2

i

2

y

2

i

2

2

r

drrTdrrT

rr

rr

rμ1

Eα

rσ

y

ii

r

r

r

r

2

2

i

2

y

2

i

2

2

θ

TrdrrTdrrT

rr

rr

rμ1

Eα

rσ

rim

r

0

r

0

22

rim

r

r

r

1

3

ΔTEα

drrT

r

1

drrT

r

1

Eαrσ

rim

rim

r

0

r

0

22

rim

θ

r

r

21

3

ΔTEα

TdrrT

r

1

drrT

r

1

Eαrσ

rim

Temperature induced stresses (radial and hoop):

Simplified equations for a case without a bore:

α = 1.8∙10

5

°C

-1

E = 6.9∙10

4

MPa

ΔT = 55 °C

σ

@r=0

= 46 MPa

Example

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 27

Rotor stress – temperature gradients

Control mode ΔT first stage ΔT exhaust

Partial arc 94°C 61°C

Throttle 46°C 28°C

Sliding 3°C 18°C

• The HPT-example shows a load change

from full to 1/3 load

• IPT swallowing capacity and re-heater

temperature controls the HPT back-

pressure

3°C

46°C

94°C

18°C

28°C

61°C

Enthalpy

Entropy

3

1

36.8

12.3

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 28

Fatigue – low or high?

Life cycles, [n]

Stress amplitude, [σ

a

]

Low-cycle fatigue High-cycle fatigue

Fatigue limit

σ

σ

a

σ

a

Time

Stress

Failure

No failure – no crack initiation

10

5…7

Wöhler- or σ,N curve

Based on Tanuma & Tadashi, “Advances in Steam Turbines for Modern Power Plants”

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 29

Casing wall temperature probe

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 30

Avancerad turbinregulator

T

r

T

Center

T

Average

T

Steam

T

Surface

ΔT

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 31

Aged deterioration – failures

MaterialPerformance

Creep

Embrittlement

Fatigue

Environment

assisted crack

Thermal

fatigue

Low-cycle

fatigue

Fretting

Dynamic SCC*

Static SCC*

Corrosion

fatigue

Crack

Crack

Crack

Crack

Crack

Crack

Crack

Brittle fracture

Softening

Creep

Wear/rubbing

Erosion/FAC

Scale deposition

Type of deterioration

Mode of deterioration

Damage or incidence

Loosening

Deformation

Efficiency decrease

Efficiency decrease

Efficiency decrease,

stick, rubbing

HP/IP shroud, blade groove, HP/IP casing,

main pipes, main valves

HP/IP rotor

HP/IP heat groove, bottom of blade root

groove

LP last blades groove of LP rotor, HP/IP

casings

HP/IP blade groove of rotor

Blade groove of LP rotor

Blade groove of LP rotor

Blade root and groove, shroud and profile

Casing bolts (high temperature)

HP/IP diaphragm nozzle plate (impulse),

HP/IP rotor and inner casings (leak)

Seals, bearings, valve shafts

Control stage nozzle and LP last stages

HP/IP nozzles and blades, main valves

Typical damaged portion

*Stress corrosion cracking

Based on Tanuma & Tadashi, “Advances in Steam Turbines for Modern Power Plants”

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 32

Environment assisted crack

Corrosive environment

Materials

Stress

Environment

•SCC

• Dynamic SCC

• Corrosion fatigue

• Static stress

• Repetitive stress

• Vibration stress

• Strength – high is more

suspicious for SCC

• Impurities etc.

• Temperature

• Wetness*

• Dissolved oxygen

• Impurities in steam

• Start-up and shutdown

*Wilson zone

Based on Tanuma & Tadashi, “Advances in Steam Turbines for Modern Power Plants”

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 33

Turbine damage – erosion

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 34

Solid particle erosion (SPE)

Ken Cotton, ”Evaluating and Improving Steam Turbine Performance”, 2

nd

ed.

N.B. This is a very design

specific problem!!!

Lund University / LTH / Energy Sciences / TPE / Magnus Genrup / 2017-10-25 Page 35

Turbine damage – rubbing