1

July 2023

BNSF RAILWAY COMPANY

GUIDELINES FOR INDUSTRY

TRACK PROJECTS

Engineering Services

Track & System Design

2600 Lou Menk Drive, Fort Worth, TX 76131

July 2023

2

July 2023

Design Guidelines for Industry Track Projects

July 2023

Table of Contents Page

1. General Procedure for Industrial Track Projects 4

2. Standards for Industrial Trackage (Non-Unit) 7

3. Standards for Unit Train/Loop Facilities 12

4. Survey and Plan Requirements 17

5. Specifications for Construction of Industrial Trackage by Private Contractor 23

6. Track Inspection Acceptance Checklist 31

7. Requirements for Working on BNSF Right of Way 32

Appendix List Page

Procedures for Continuous Welded Rail in Industry Tracks A-1 -11

Preliminary Conceptual Sketch Example A-12

Standard Sections for Industry Track A-13 – 15

Standard Turnout Pad For Industry Tracks A-16

Earthen Bumper Details A-17

No. 9 Turnout Plan and Geometry A-18 – 23

No. 11 Turnout Plan and Geometry A-24 – 29

No. 15 Turnout Plan and Geometry A-30 – 35

Double Switch Point Derail (16'-6") A-36

3

July 2023

Appendix List (cont.) Page

Switch Stand with 30 Degree Handle A-37

Switch Stand Targets A-38

Sliding Derail with Crowder A-39

Derail Sign A-40

Road Crossings A-41 – 43

Clearance Requirements and Sign A-44 – 46

Vertical Curves A-47 – 48

Underground Cable Locate Form A-49

Point of Switch and Derail Stake-out Guidelines A-50

Receipt of Design Guidelines A-51

4

July 2023

1. General Procedure for Industrial Track Projects

The purpose of this chapter is to guide the process for the development of industry tracks and facilities. Build-

ins and tracks other than industrial need to follow BNSF’s Main Line Design Guidelines for Track Projects.

1.1. Industrial Site Types: BNSF Customers should be familiar with the various site location options that

are covered by these guidelines.

1.1.1. LOGISTICS PARKS

Warehouse and distribution space located at BNSF intermodal facilities. The BNSF Logistics Park

strategy uses an intermodal hub to anchor distribution centers nearby, enabling us to partner with

trucking companies and ocean carriers and provide streamlined supply chain solutions that connect

manufacturers and retailers to their markets.

1.1.2. LOGISTICS CENTERS

BNSF-owned industrial parks that offer direct rail service. Logistics centers offer direct-rail service

in multi-customer, multi-commodity business parks. These sites are rough-graded for commercial

viability and ready for the customer to finish grade and construct their facilities.

1.1.3 CERTIFIED SITES

Private parks ready for development along our network and verified by a vigorous review process.

BNSF's Site Certification Program identifies optimal rail-served sites and conducts in-depth reviews

of ten economic development criteria to determine if the site meets BNSF’s stringent readiness

standards, which are intended to minimize development risks customers may face.

1.2. Customer will contact BNSF’s Economic Development (ED) representative. Contact information

can be found at https://www.bnsf.com/ship-with-bnsf/rail-development/build-rail-served-

facility/.

1.3. After contacting the BNSF ED representative, the customer will be asked to provide a conceptual

layout for the project. This layout should include property boundaries, existing buildings and roads,

and a general location of where the proposed tracks will be located.

BNSF will consider the feasibility of constructing the project at the desired location along with

operating issues related to product origins and destinations. BNSF will prepare a scaled track layout

(project schematic) based on the customer’s concept to ensure the desired operation meets design

standards. The project schematic will identify both BNSF’s and the customer’s scopes of work, and

then be shared with the Customer (see Appendix, page A-12 for an example). After BNSF approval

of the opportunity (New Business Review) the customer will be provided a cost estimate for BNSF’s

track and signal work.

1.4. The Customer may use a designer or contractor of its choice to prepare the track plans. Survey on

BNSF right-of-way will require the application of a temporary occupancy permit (see “Requirements

for Working on BNSF Right of Way”). The project schematic should be used as a guide for preparing

the industrial track plan. Plans should be complete with all the items in the “Final Track Plan

Checklist” included. Questions concerning these guidelines should be directed to the BNSF

Engineering representative. Customers are encouraged to reference this document, including

standard plan drawings, in the construction specifications. BNSF Engineering will review and

approve the track design, and if there are significant changes from the original project schematic,

the plan may need to be reviewed by other BNSF departments.

1.5. BNSF Engineering will communicate directly with the Customer regarding any plan revisions. Any

5

July 2023

revisions will be documented on the prints and communicated in writing to the Customer. BNSF

Engineering will notify ED when the industrial track plan has been reviewed and approved.

1.6. BNSF Engineering will prepare a cost estimate, chargeable to the Customer, which includes BNSF’s

portion of track and signal construction, as well as an appropriated amount for an

Inspector/Coordinator for construction monitoring purposes. The cost estimate does not include

flagging charges as they can vary significantly based on the approach adopted by the customer’s

contractor. In general, BNSF will construct from point of switch to the 14-ft clearance point for

manual switches, and from the point of switch to just beyond the power derail and the approach

signal for powered switches. The Inspector/Coordinator will serve as a BNSF representative related

to grading on BNSF R/W, utility drops, turnout installation schedules and customer track

construction inspection.

1.7. Upon receiving the Firm Bid Cost Estimate, ED will present the formal industrial track package,

including all agreements and cost proposal, to the Customer for consideration.

1.8. Upon Customer's acceptance of the proposal (check, fully executed agreements, and submittal of

the final plans) ED will notify all concerned the project has been approved and funded.

1.9. The final plans must be approved by BNSF Engineering prior to the execution of the contractor’s

right of entry, which limits when work can start on BNSF property. Materials for BNSF’s portion of

the project are then ordered, work scheduled, and construction completed, which can take up to

27 weeks. Customers should note that turnout construction pads must be completed 6 weeks or

more (dependent on territorial restrictions) before the target construction completion timeline to

allow time to deliver, assemble, and install the turnout at the designed location.

6

July 2023

Following is the timeline for a typical industry track project:

STAGE ACTIVITY START END TIMELINE

1

New opportunity

conceptual layout request

Conceptual layout

request received

Conceptual layout

delivered to ED Mgr.

1 week

2

New Business Review

(internal BNSF assessment)

NBR created NBR completed 2 weeks

3

Project schematic approval &

cost estimate preparation

NBR completed

notification

BNSF cost estimates

completed

9 weeks

4

Customer acceptance

& payment

Proposal letter sent Check deposited 9 weeks

5

Request for capital Check deposited

/ CPAR approved

AFE approved 3 weeks

6

Track & signal materials

ordered and delivered

AFE approved Track and signal

material

delivered

17 weeks

7

Track & signal construction Customer

agreements &

contracts executed

Track and signal

construction

complete

13 weeks

8

Engineering & Construction

complete

Final customer track

inspection

completed

Actual project in

service date entered

in ESI

2 week

9

Customer moves cars

into facility

Project Closeout

Actual project in

service date entered

in ESI

CDI, CRF & Credit

complete

1 week

Total Engineering and

Construction timeline

57 weeks

7

July 2023

2. Standards for Industrial Trackage (Carload, or Non-Unit Facilities)

2.1 Roadbed: Roadbed and ballast section for industrial trackage shall conform to the special roadbed

section (see Appendix, page A-13), and to the ballast material requirements on page 27.

2.2 Curvature: Usual maximum degree of curve for tracks operated on and/or maintained by BNSF shall not

exceed 10° (574.69' radius). All curves are defined using the chord definition. Minimum tangent

lengths between reversing curves must meet AREMA Chapter 5, Table 5-3-11. No turnouts

(switches) can be placed in a curve.

Curves exceeding 10⁰ will require review and approval from BNSF Engineering. Such curves may

require mitigation measures, at BNSF’s discretion:

Carload, or Non

-

Unit Facilities

Curvature

< 7

⁰30'

7⁰30' to <10⁰

10

⁰ to 14⁰30'

> 14

⁰30'

Mitigation(s)

Required

None; premium

fasteners

preferred

Premium Fasteners Premium Fasteners No cars longer than

85'

Tie integrity: Class 3

tie condition

Premium Fasteners

Rail size per BNSF EI

Table 6-2

Tie integrity: Class 5

tie condition

Tie plate cutting/rail

seat abrasion per

BNSF EI 7

Rail wear per BNSF

EI 6 Table 6-1

Rail size per BNSF EI

6 Table 6-2

Optional

:

Gage face

lubrication

Top of rail friction

modifier

2.3 Profile Grade: Track profile grades shall be limited to a maximum of 1.5%.

2.4 Vertical Curves: Vertical curves must be provided at break points in profile grade. The rate of change

shall not exceed 2.0 in summits or sags. Vertical curves shall not extend into limits of turnout switch

ties. See Appendix, pages A-47 and A-48 for BNSF's standard for vertical curves.

2.5 Track: Recommended rail section is 115-lb. or greater. See Page 26 for further information on rail

sections. Hardwood ties shall be new 7” X 8” (No. 4) or 7” X 9” (No. 5), 8’-6” long, placed on 21.5"

centers with a 6” ballast section. Rail anchorage shall be provided at a minimum rate of 16 anchors

per 39' panel. Continuous welded rail (CWR) shall be box-anchored every other tie. Concrete ties

can be spaced at 28” center to center with an 8” ballast section. CWR is recommended when using

concrete ties. M-8 steel ties (8mm or 5/16” section) can be used in non-unit facility tracks and are

spaced at 24” centers with 8” ballast section.

8

July 2023

2.6 Turnouts: All main line, controlled siding and passing track turnouts will be a minimum new No. 11-

141 lb. and include either a spring-rail frog or a rigid, railbound manganese frog, as specified by

BNSF Engineering. For other turnouts maintained by BNSF, the size and weight will be determined

dependent upon the transportation commodity, with a No. 11-141 lb. recommended, and a No. 9 -

115 lb. as the minimum (see Appendix, pages A-18 to A-35). Main line turnout switch ties shall be

new and hardwood. All mainline, controlled siding and passing track turnouts and trackage are to

be placed by BNSF personnel out to the 14' clearance point.

Mainline, controlled siding and passing track turnouts will require the placement of a construction

pad alongside the track to allow assembly of the turnout, with no disruption to traffic. After the

turnout is assembled, a track window is obtained to remove the trackage and insert the turnout. An

example of a construction pad is shown in the Appendix on page A-16. For turnouts placed off of

BNSF property and/or maintained by the Customer, and operated by BNSF, the recommended

minimum is a No. 9 - 115 lb. All switch stands need to include a "30 Degree" handle (see Appendix,

page A-37), and a target with alternating green and yellow colors indicating switch position (page A-

38).

Switch heaters are required for mainline turnouts where snow and ice present operational

challenges. If a power turnout requires a switch heater, the power derail will require one also. The

cost estimate will include installation of the switch heaters when required.

Mainline turnouts must be placed at least 200 feet from the end of a mainline curve. Industry

turnouts within the facility must be placed at least 50 feet from the end of any curve.

Minimum tangent lengths from PT of equivalent turnout curve to any curve at the heel end of a

turnout shall not be less than AREMA Chapter 5, Table 5-3-11

2.7 Derails: A derail shall be placed on all tracks connecting with a main line, siding, or industrial lead.

Derails protecting mainline tracks and controlled sidings shall be double switch point or sliding derail

with crowder (see BNSF Standard Plan 2400) and installed so that the derailed car is directed away

from BNSF trackage. Use of sliding derails must be approved by the Division GM.

A power derail is required when the mainline turnout is powered, and BNSF will install track and

signal from the point of switch to the insulated joints just beyond the power derail. Derails

protecting mainline tracks shall be placed a minimum of 100 feet behind the 14' clearance point

and placed on tangent track where possible. Derails protecting other-than-mainline tracks shall be

placed a minimum of 50 feet behind the 14' clearance point and placed on tangent track where

possible. The type of derail and actual location may be determined by BNSF Operating Department

requirements. A “Derail” sign needs to be placed next to the derail, BNSF Standard 3028 or

otherwise approved.

2.8 Structures: Bridges, drainage structures, track hoppers, retaining walls, etc. shall be designed to

carry Cooper E-80 live load with diesel impact. Structures shall be designed per American Railway

Engineering and Maintenance of Way Association (AREMA) Manual chapters 1, 7, 8, or 15 as

applicable, and designed by a licensed engineer. See AREMA standards for unloading pits (Chapter

15, Section 8.4). All structural plans will need to be reviewed and accepted by BNSF Engineering.

Gratings covering open pits must be bolted in place.

If a project creates the need for existing structures (including BNSF’s structures) to be modified, the

modifications shall be accounted into the customer’s scope of work of the project, subjected to

BNSF’s review and approval. For drainage related structures, additional information is included in

“Culverts” section within the “Specifications for Construction of Industry Trackage by Private

Contractor” chapter.

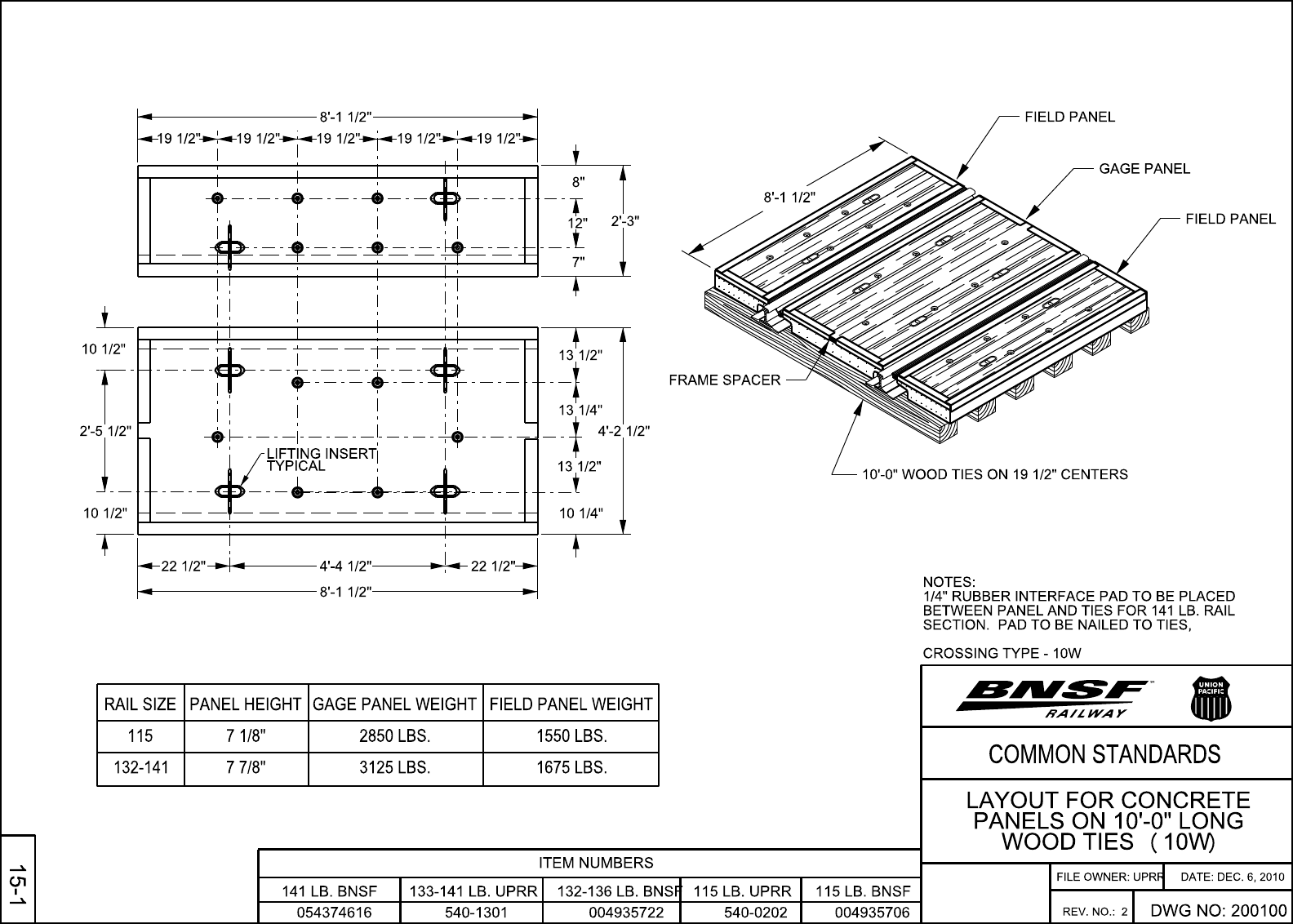

2.9 Road Crossings: The standard for a road crossing surface installed and maintained by the BNSF is

9

July 2023

concrete plank (for 141-lb. rail) placed on 10-ft. switch ties. Also, ten each 10-ft. switch ties are

placed on both ends of the crossing, replacing any standard crossties. For crossings installed and

maintained by the Customer, a concrete plank is recommended, with a wood plank surface as

acceptable (see Appendix, pages A-41 to A-43).

2.10 Clearances: BNSF will adhere to the "Clearance Requirements by State," BNSF Dwg. No. 2509, Sheet

No. 2 (see Appendix, page A-44) for each state. If a state does not have its own clearances, the

"BNSF Minimum Clearances Diagram," BNSF Dwg. No. 2509, Sheet No. 1 (see Appendix, page A-

45) will apply. Side clearances for curves should have an additional 1-1/2" per degree of curvature.

All effort should be made to provide adequate clearances. In the event clearances cannot be

provided for as prescribed, warning signs will be installed and they must be illuminated at night (see

Appendix, page A-46). Any clearances not meeting State or BNSF requirements must be reviewed

and approved by BNSF Engineering.

All loading/unloading equipment that fouls the clearance envelope during operation must positively

lock in a non-fouling position when not in use.

All new tracks constructed will maintain a minimum distance of 25 feet for track centers from any

main track, controlled siding or passing track. New tracks adjacent to other tracks will maintain a

minimum distance of 14 feet for track centers.

At road crossings the set-back distance for storing rail cars on multiple adjacent tracks (track centers

less than 25') is 250 feet from the edge of roadway. For single tracks, the setback distance varies for

each state and is regulated by the states' appropriate agencies, but 150 feet from the edge of

roadway is the minimum. However, operating conditions may require greater distances.

2.11 Walkways: Walkways on bridges and adjacent to switches and trackage are governed by the

appropriate State Public Service Commission, Railway Commission, or other State and/or Federal

agencies. However, the example on page A-11 depicts requirements for most states. Walkway ballast

shall be BNSF Class 2 (AREMA Size 5) and no larger than 1” in size (ballast gradation shown on page

24).

2.12 Signals and Utility Service: Customer shall provide electrical service to BNSF property should the

proposed trackwork require power for the signal facilities. The requirement and locations will be

identified by BNSF Engineering and communicated to the customer. If the service will include

providing power to one or more switch heaters, a minimum of 200 Amp, Single Phase, 120/240-volt

service, with meter socket and service disconnect is required. The service disconnect shall be a

minimum of 200 amp, 2 pole breaker by either Cutler Hammer or Square D (QO style), with the

meter socket requirement as per the power company specifications. No additional electrical panels

are necessary as BNSF will take a feeder from the load side of the 200-amp service disconnect

switch. The service may be either overhead or underground. All electrical installations will be made

in accordance with the prevailing State/local electrical code(s), or if there is none, the current edition

of the National Electrical Code will govern the installation. If an electric switch heater is not involved,

100 Amp service will be sufficient.

Customer shall also provide natural gas service to BNSF property should the proposed trackwork

require the installation of one or more switch heaters. The requirement and locations will be identified

by the BNSF project representative. The service shall be capable of delivering 600- 900 thousand BTUs

per heater per location required. The actual pressure shall be requested from BNSF for each project

specifically (typical pressure should be around 6 psi).

2.13 Inspection of Materials and Track: BNSF's Engineering representative should inspect all track

materials prior to placement to avoid subsequent removal of sub-standard material. BNSF

personnel will inspect the completed track before placing it into service.

10

July 2023

2.14 General:

2.14.1 Loading and unloading tracks must be designed so that they are completely independent

of railroad operating lines and passing tracks such that loading and unloading operations

in no way interfere with train operations. Design of trackage must be approved by BNSF

Engineering.

2.14.2 Utility installations may require a permit. Refer to "BNSF Utility Accommodation Policy"

booklet (https://www.bnsf.com/bnsf-resources/pdf/about-bnsf/utility.pdf). Pipelines

under track are to be encased per BNSF requirements. Wirelines are to be installed per

BNSF requirements. Utilities within 50 feet beyond the end of track must be underground

and protected as if they were under the track.

2.14.3 The effect on sight distance must be considered when planning construction of trackage

in the vicinity of any grade crossings. The required sight distance should be determined

and preserved when performing and designing for construction near any grade crossing.

Less than the required sight distance will be the liability of the Customer.

2.14.4 Maintenance of Way Operating Rule No. 6.32.4: "Leave cars, engines, or equipment clear

of road crossings and crossing signal circuits. If possible, avoid leaving cars, engines, or

equipment standing closer than 250 feet from the road crossing when there is an adjacent

track (<25' track centers)."

2.14.5 The effect on queuing distance of a crossing must be considered when planning the

extension of a track across a grade crossing. The proposed plans shall not cause vehicles

to be trapped in between tracks, cause vehicles to have to stop on a track while waiting

in queue for a crossing to clear, or to cause excessive highway congestion by reducing the

queuing distance of an existing crossing. Adding new public crossings or adding more

tracks to an existing public crossing will be reviewed by BNSF Engineering and the

appropriate entity with jurisdiction over the crossing (Typically the State’s Department of

Transportation).

2.14.6 An earthen berm (see Appendix, page A-17) or suitable bumping post shall be installed at

the end of track. Also, a red retro-reflective marker shall be placed at the end of track.

2.14.7 Customer is responsible for all grading including placing all subballast up to BNSF ballast

and the placement of a construction pad. BNSF rough site grading is for general

commercial viability. Customer understands that they may need to perform additional

grading based on customer needs for operation of their location.

2.14.8 Customer is to acquire any additional property required to construct grade and drainage.

If the proposed trackage or facility will increase runoff onto BNSF property, a detailed

drainage plan needs to be submitted for review prior to construction. Drainage should be

handled in a manner as not to increase current drainage structures on BNSF property.

2.14.9 Contractor must not at any time foul the main line tracks. A BNSF flagman will be required,

at the Contractor's expense, when working within 25 feet from centerline of the track,

which would include, but not limited to, work that could foul a track, such as with a large

crane, excavation activities that could undermine a track, and overhead wire work which

could potentially fall onto the track. Billing for the flagman is separate from the cost for

BNSF portion of the track work. Current cost for BNSF flagging is approximately

11

July 2023

$1,800 per day with billing based on actual charges.

2.14.10 Appropriate access must be provided for BNSF to drive an SU-40 maintenance truck (See

AASHTO’s “A Policy on Geometric Design of Highways and Streets”, a.k.a. the “AASHTO

Green Book”) to the proposed installations to be installed and/or maintained by BNSF or

other existing BNSF infrastructure. If switch heaters are required at locations where the

installation of a natural gas supply is infeasible, the access must be sufficient for refueling

trucks to access the switch heater area. Depending on the location and the fuel providers

of the region, refueling trucks may exceed the size of a SU-40 vehicle. Additional

requirements related to the backing up of vehicles may be active in certain operating

regions, which affects turnaround designs. Consult your project representative for

additional region-specific requirements.

12

July 2023

3. Standards for Unit Train/Loop Facilities

3.1 Roadbed: Roadbed and ballast section for industrial trackage shall conform to the special roadbed

section (see Appendix, page A-13), and to the ballast material requirements on page 24.

3.2 Curvature: Maximum degree of curve shall not exceed 7⁰30' (764.49' radius). All curves are defined

using the chord definition method. Minimum tangent lengths between reversing curves must meet

AREMA Chapter 5, Table 5-3-11. No turnouts (switches) can be placed in a curve.

Curves exceeding 7⁰30' will require review and approval from BNSF Engineering. Such curves may

require one or more of the following mitigation measures, at BNSF’s discretion:

Unit Train

Curvature

<

7

⁰30'

7

⁰30' to

<

10

⁰

10

⁰ to < 14⁰30'

≥

14

⁰30'

Mitigation

Required

None;

premium

fasteners

preferred

Premium

Fasteners

Premium Fasteners No cars longer than 85'

Tie integrity: Class 3

tie condition

Premium Fasteners

Tie plate cutting/rail

seat abrasion per

BNSF EI 7

Tie integrity: Class 5 tie

condition

Rail wear per BNSF EI

Table 6-1

Tie plate cutting/rail

seat abrasion per BNSF

EI 7

Rail size per BNSF EI

Table 6-2

Rail wear per BNSF EI

Table 6-1

Rail size per BNSF EI

Table 6-2

Optional:

Gage face lubrication

Top of rail friction

modifier

3.3 Profile Grade: Track profile grades shall be limited to a maximum of 1.5%. For loop tracks, the

maximum grade will be 0.5%. Other restrictions may be defined for individual projects. A flat grade

(0.0%) should be maintained through loading/unloading areas, with a maximum 0.20% grade

sloping downwards away from BNSF main or connecting track.

3.4 Vertical Curves: Vertical curves must be provided at break points in profile grade. The rate of change

shall not exceed 1.0 in summits or 0.5 in sags. Vertical curves shall not extend into limits of turnout

switch ties. See Appendix, pages A-47 and A-48 for BNSF's standard for vertical curves.

3.5 Track: For New Unit Train Facilities minimum rail section is 115-lb and continuous welded rail (CWR)

is recommended. Hardwood ties shall be new 7” X 8” (No. 4) or 7” X 9” (No. 5), 8’-6” long, placed on

21.5" centers with a 6” ballast section. Rail anchorage shall be provided at a minimum rate of 16

anchors per 39' panel. Continuous welded rail (CWR) shall be box-anchored every other tie.

13

July 2023

Concrete ties can be spaced at 28” center to center with an 8” ballast section. CWR is recommended

when using concrete ties. M-10 steel ties (10mm or 13/32” section) can be used in unit facility tracks

and are spaced at 24” centers with 8” ballast section.

3.6 Turnouts: All main line, controlled siding and passing track turnouts will be a minimum new No. 11-

141 lb. and include either a spring-rail frog or a rigid, railbound manganese frog, as specified by

BNSF Engineering. For other turnouts maintained by BNSF, a No. 11-115 lb. is the minimum (see

Appendix, pages A-22 to A-33). Main line turnout switch ties shall be new and hardwood. All

mainline, controlled siding and passing track turnouts and trackage are to be placed by BNSF

personnel out to the 14' clearance point. All joints on the side of turnout receiving majority of traffic

will be thermite welded.

Mainline, controlled siding and passing track turnouts will require the placement of a construction

pad alongside the track to allow assembly of the turnout, with no disruption to traffic. After the

turnout is assembled, a track window is obtained to remove the trackage and insert the turnout. An

example of a construction pad is shown (see Appendix, page A-16).

For turnouts placed off of BNSF property and/or maintained by the Customer, and operated by BNSF,

a No. 11 - 115 lb. turnout will be the minimum. All switch stands need to include a "30 Degree"

handle (see Appendix, page A-37), and a target with alternating green and yellow colors indicating

switch position (page A-38).

Switch heaters are required for mainline turnouts where snow and ice present operational

challenges. If a power turnout requires a switch heater, the power derail will require one also. The

cost estimate will include installation of the switch heaters when required.

Mainline turnouts must be placed at least 200 feet from the end of a mainline curve. Industry

turnouts within the facility must be placed at least 100 feet from the end of any curve. Minimum

tangent lengths from PT of equivalent turnout curve to any curve at the heel end of a turnout shall

not be less than AREMA Chapter 5, Table 5-3-11

3.7 Derails: A derail shall be placed on all tracks connecting with a main line, siding, or industrial lead.

Derails protecting mainline tracks and controlled sidings shall be double switch point or sliding derail

with crowder (see BNSF Standard Plan 2400) and installed so that the derailed car is directed away

from BNSF trackage. Use of sliding derails must be approved by the Division GM.

A power derail is required when the mainline turnout is powered, and BNSF will install track and

signal from the point of switch to the insulated joints just beyond the power derail. Derails

protecting mainline tracks shall be placed a minimum of 100 feet behind the 14' clearance point

and placed on tangent track where possible. Derails protecting other-than-mainline tracks shall be

placed a minimum of 50 feet behind the 14' clearance point and placed on tangent track where

possible. The type of derail and actual location may be determined by BNSF Operating Department

requirements. A “Derail” sign needs to be placed next to the derail, BNSF Standard 3028 or

otherwise approved.

3.8 Structures: Bridges, drainage structures, track hoppers, retaining walls, etc. shall be designed to

carry Cooper E-80 live load with diesel impact. Structures shall be designed per American Railway

Engineering and Maintenance of Way Association (AREMA) Manual chapters 1, 7, 8, or 15 as

applicable, and designed by a licensed engineer. See AREMA standards for unloading pits (Chapter

15, Section 8.4). All structural plans will need to be reviewed and accepted by BNSF Engineering.

Gratings covering open pits must be bolted in place.

If a project creates the need for existing structures (including BNSF’s structures) to be modified, the

modifications shall be accounted into the customer’s scope of work of the project, subjected to

BNSF’s review and approval. For drainage related structures, additional information is included in

“Culverts” section within the “Specifications for Construction of Industry Trackage by Private

Contractor” chapter.

14

July 2023

3.9 Road Crossings: The standard for a road crossing surface installed and maintained by the BNSF is

concrete plank (for 141-lb. rail) placed on 10-ft. switch ties. Also, ten each 10-ft. switch ties are

placed on both ends of the crossing, replacing any standard crossties. For crossings installed and

maintained by the Customer, a concrete plank is recommended, with a wood plank surface as

acceptable (see Appendix, pages A-41 to A-43).

3.10 Clearances: BNSF will adhere to the "Clearance Requirements by State," BNSF Dwg. No. 2509, Sheet

No. 2 (see Appendix, page A-44) for each state. If a state does not have its own clearances, the

"BNSF Minimum Clearances Diagram," BNSF Dwg. No. 2509, Sheet No. 1 (see Appendix, page A-

45) will apply. Side clearances for curves should have an additional 1-1/2" per degree of curvature.

All effort should be made to provide adequate clearances. In the event clearances cannot be

provided for as prescribed, warning signs will be installed and they must be illuminated at night (see

Appendix, page A-46). Any clearances not meeting State or BNSF requirements must be reviewed

and approved by BNSF Engineering.

All loading/unloading equipment that fouls the clearance envelope during operation must positively

lock in a non-fouling position when not in use.

All new tracks constructed will maintain a minimum distance of 25 feet for track centers from any

main track, controlled siding or passing track. New tracks adjacent to other tracks will maintain a

minimum distance of 14 feet for track centers.

At road crossings the set-back distance for storing rail cars on multiple adjacent tracks (track centers

less than 25') is 250 feet from the edge of roadway. For single tracks, the setback distance varies for

each state and is regulated by the states' appropriate agencies, but 150 feet from the edge of

roadway is the minimum. However, operating conditions may require greater distances.

3.11 Walkways: Walkways on bridges and adjacent to switches and trackage are governed by the

appropriate State Public Service Commission, Railway Commission, or other State and/or Federal

agencies. Due to revised FRA Airbrake and Train Handling Rules, outbound trains are required to

have an airbrake inspection on both sides of the train. New shuttle projects will be required to have

a minimum 13' inspection road on one side and a minimum 8.5' walkway on the other. See Appendix

pages A-14 and A-15 for typical sections of roads and walkways. Walkway ballast shall be BNSF Class

2 (AREMA Size 5) and no larger than 1” in size (ballast gradation shown on page 24).

3.12 Signals and Utility Service: Customer shall provide electrical service to BNSF property should the

proposed trackwork require power for the signal facilities. The requirement and locations will be

identified by BNSF Engineering and communicated to the customer. If the service is for an electric

switch heater, a 200 Amp, Single Phase, 120/240-volt service, with meter socket and service

disconnect is required. The service disconnect shall be a 200 amp, 2 pole breaker by either Cutler

Hammer or Square D (QO style), with the meter socket requirement as per the power company

specifications. No additional electrical panels are necessary as BNSF will take a feeder from the load

side of the 200 amp service disconnect switch. The service may be either overhead or underground.

All electrical installations will be made in accordance with the prevailing State/local electrical

code(s), or if there is none, the current edition of the National Electrical Code will govern the

installation. If an electric switch heater is not involved, 100 Amp service will be sufficient. Customer

shall also provide natural gas service to BNSF property should the proposed trackwork require the

installation of one or more switch heaters. The requirement and locations will be identified by the

BNSF project representative. The service shall be capable of delivering 600- 900 thousand BTUs per

heater per location required. The actual pressure shall be requested from BNSF for each project

specifically (typical pressure should be around 6 psi).

3.13 Access Road: Unless otherwise directed a road will be required that will provide access to inspect

15

July 2023

the entire train prior to movement from the facility. Due to revised FRA Airbrake and Train Handling

Rules, outbound trains are required to have an airbrake inspection on both sides of the train. New

shuttle projects will be required to have a minimum 13' inspection road on one side and a minimum

8.5' walkway on the other. See Appendix pages A-14 and A-15 for typical sections of roads and

walkways. A standard section with a 13-ft wide roadway is shown in the Appendix, page A-15. The

roadway can be constructed using subballast materials as specified in the Grading & Embankment

section of this document, page 20.

3.14 Inspection of Materials and Track: BNSF's Engineering representative should inspect all track

materials prior to placement to avoid subsequent removal of sub-standard material. BNSF

personnel will inspect the completed track before placing it into service.

3.15 General:

3.15.1 Loading and unloading tracks should be designed so that they are completely independent

of railroad operating lines and passing tracks such that loading and unloading operations in

no way interfere with train operations. Design of trackage must be approved by BNSF

Engineering.

3.15.2 Utility installations may require a permit. Refer to "BNSF Utility Accommodation Policy"

booklet (https://www.bnsf.com/bnsf-resources/pdf/about-bnsf/utility.pdf).Pipelines

under track are to be encased per BNSF requirements. Wirelines are to be installed per BNSF

requirements. Utilities within 50 feet beyond the end of track must be underground and

protected as if they were under the track.

3.15.3 The effect on sight distance must be considered when planning construction of trackage in

the vicinity of any grade crossings. The required sight distance should be determined and

preserved when performing and designing for construction near any grade crossing. Less

than the required sight distance will be the liability of the Customer.

Maintenance of Way Operating Rule No. 6.32.4:

"Leave cars, engines, or equipment clear of road crossings and crossing signal circuits. If

possible, avoid leaving cars, engines, or equipment standing closer than 250 feet from

the road crossing when there is an adjacent track (<25' track centers)."

3.15.4 The effect on queuing distance of a crossing must be considered when planning the

extension of a track across a grade crossing. The proposed plans shall not cause vehicles

to be trapped in between tracks, cause vehicles to have to stop on a track while waiting in

queue for a crossing to clear, or to cause excessive highway congestion by reducing the

queuing distance of an existing crossing. Adding new public crossings or adding more tracks

to an existing public crossing will be reviewed by BNSF Engineering and the appropriate

entity with jurisdiction over the crossing (Typically the State’s Department of

Transportation).

3.15.5 An earthen berm (see Appendix, page A-17) or suitable bumping post shall be installed at

the end of track. Also, a red retro-reflective marker shall be placed at the end of track.

3.15.6 Customer is responsible for all grading including placing all subballast up to BNSF ballast

and the placement of a construction pad, if required. BNSF rough site grading is for general

commercial viability. Customer understands that they may need to perform additional

grading based on customer needs for operation of their location.

16

July 2023

3.15.7 Customer is to acquire any additional property required to construct grade and drainage.

If the proposed trackage or facility will increase runoff onto BNSF property, a detailed

drainage plan needs to be submitted for review prior to construction. Drainage should be

handled in a manner as not to overload current drainage structures on BNSF property.

3.15.8 Contractor must not at any time foul the main line tracks. A BNSF flagman will be required,

at the Contractor's expense, when working within 25 feet from centerline of the track,

which would include, but not limited to, work that could foul a track, such as with a large

crane, excavation activities that could undermine a track, and overhead wire work which

could potentially fall onto the track. Billing for the flagman is separate from the cost for

BNSF portion of the track work. Current cost for BNSF flagging is approximately $1,800 per

day with billing based on actual charges.

3.15.9 Adequate lighting must be provided for train crews working at night. Work areas near

switches, gates, doors, pits and buildings should be illuminated to prevent walking/tripping

hazards and allow crewmen riding rail cars to see without reliance upon a flashlight.

3.15.10 A track to set out bad order cars unsuitable for loading or unloading needs to be added

to the overall design. Set out track should be long enough to place at least 5 rail cars and

be accessible to a repair crew. A locomotive tie-up track may also need to be

incorporated into the design. This need will be determined at the on-site meeting.

3.15.11 Appropriate access must be provided for BNSF to drive an SU-40 maintenance truck (See

AASHTO’s “A Policy on Geometric Design of Highways and Streets”, a.k.a. the “AASHTO

Green Book”) to the proposed installations to be installed and/or maintained by BNSF or

other existing BNSF infrastructure. If switch heaters are required at locations where the

installation of a natural gas supply is infeasible, the access must be sufficient for refueling

trucks to access the switch heater area. Depending on the location and the fuel providers

of the region, refueling trucks may exceed the size of a SU-40 vehicle. Additional

requirements related to the backing up of vehicles may be active in certain operating

regions, which affects turnaround designs. Consult your project representative for

additional region-specific requirements.

17

July 2023

4. Survey and Plan Requirements

4.1 Surveying on BNSF Right of Way: In order to protect BNSF's investment of its Right of Way (ROW)

and for the safety of persons coming onto BNSF property, BNSF requires all parties entering or

performing work on the right-of-way to secure appropriate agreement and insurance before

beginning any type of work. Please consult the BNSF project representative and the section

“Requirements for Working on BNSF Right of Way” before proceeding.

4.1.1 Grading and alignment stake out and re-staking is the responsibility of the customer,

including the portions to be installed by BNSF forces. BNSF project stake out shall not

include the point of intersection (PI). All stake out locations shall be documented by

photographs. We encourage marking up photographs to demonstrate the stakes’

corresponding feature to minimize misunderstanding. They shall be sent to the BNSF project

representative (the BNSF inspector coordinator) when completed. The stakeout guidelines

listed below illustrate the various responsibilities of the customer relative to the stage of

the project:

Project Stage

Pt. of Switch (PSw)

Power Switch Projects Only

Pt. of Derail (Derail)

Alignment

Conceptual: Allows for

proper visualization of

preliminary site visit.

Pad Completion:

Enables crews to

unload and assemble

the switch

at the

correct locations.

Pre

-

Install Stake Out:

These staked items will

be communicated to

the BNSF during the

pre-

install meeting.

4.1.1.1 Point of Switch: A one page document has been included in A-50 of the Appendix. This stake

out shall include rail markings and center of track markings at a minimum. An offset stake

is encouraged after the pad is completed. A flagger will be needed for this stake out due to

the need to foul the track.

4.1.1.2 Point of Derail: BNSF will construct and install up to the entering signal for the power

switch’s control point for projects involving power switches. The power derail shall be

marked with both a centerline feather and an offset stake. The stake out shall follow the

format included in the point of switch stake out document on A-50 of the Appendix with

the only difference being replacing “PSw” by the word “Derail”.

4.1.1.3 Alignment: BNSF will construct and install up to the entering signal for the power switch’s

control point for projects involving power switches. The alignment stake out shall start from

the last long tie to the entering signal’s location. Stakes should be in intervals of 100’ or less

and should include centerline feathers and offset stakes at the edge of the pad or a location

that will not be easily damaged by construction equipment.

18

July 2023

4.2 Plan Requirements: All plans and drawings need to be prepared electronically in a CADD format.

This allows for updates to BNSF's maps and records to be done electronically. All information is to

be in English units. Plan submittals should be in Adobe’s Acrobat pdf format, with 11” x 17” sheet

size. Plan submittals must include completed checklists (see pages 19-22). Upon approval, BNSF

Engineering will revise the project schematic, if necessary.

Plan View Scale: 1” = 50’

Profile View Scale: 1” = 50’ horizontal and 1” = 5’ vertical

Cross Sections Scale: 1”=10’ horizontal and vertical

4.2.1 BNSF Engineering Plan Submittals – Definitions

Conceptual – An alignment plan showing existing track and features along with proposed

changes, and the official operating plan. This will be used for the New Business Review

(NBR).

30% Design – All items from the conceptual submittal plus plan/profile sheets, cross-

sections, typical sections, at-grade crossing plans, drainage plans, revisions from changes due

to land and utility negotiations, and 30% structure plans. This plan will be used for the walk-

thru inspection and schematic approval.

90% Design - All items from the 30% submittal plus revisions from the walk-thru inspection,

culvert extensions, at-grade crossing plans, and 60% structure plans (e.g. pit plans, catwalks,

and sheds).

Final Track Plan – All items in 30% and 90% with all relevant details and revisions

incorporated from previous comments. Specifications and details included.

As-Built Submittal – The plan/profile sheets updated with post-construction locations as

surveyed.

4.2.2 Provide an Operating Plan

Prepare a sketch (does not have to be to-scale) showing in-bound and out-bound switching

plans and lengths of tracks to be used. Prepare multiple sketches to show the position of

cars and locomotives at different stages of switching/loading/unloading together with a

narrative describing the movements depicted by the multiple sketches.

In developing track lengths for operating plans, designers shall be aware that:

- Switches cannot be thrown unless the closest on track equipment is at least 50’ from

the point of switch

- Cars shall not come within 25’ of the end of track bumper at any time

- Parked cars shall be at least 50’ or more from the clearance point of a turnout if the

other side of the turnout is to be safely used by BNSF crews.

- If a power turnout is required, industry switching cannot come within 50’ of the

proposed entering signal location of the control point

- If a manual turnout and derail is used, industry switching cannot come within 50’ of

the proposed point of derail location

Customers are encouraged to reference this document, including standard plan drawings,

in the construction specifications.

19

July 2023

Conceptual Plan Submittal Checklist:

Furnish Milepost and Line Segment in the Title Block, along with name of Industry and date of plan

preparation. Contact information for engineering firm should also be included on plans.

BNSF Milepost location and BNSF stationing information for switches on proposed on BNSF tracks

(Lat/Long information for power switch projects)

Curvatures not exceeding 7-30 (unit train) or 10-00 (manifest) without BNSF Approval

Design will conceptually allow grades not exceeding 0.5% on receiving/departure tracks

Design will conceptually allow grades not exceeding 1.5% on any tracks

Track centerline distances from BNSF mainline and for inspection roads & ATV inspection paths

Switch sizes for all switches

Culverts to be abandoned/extended/replaced for those under BNSF tracks

Designated unit train receiving/departure tracks and/or manifest tracks

Added tracks across existing BNSF at grade crossings, or additional crossings proposed across

public roadways

Additional bridges next to existing BNSF infrastructure

Distances from proposed turnouts to existing critical BNSF infrastructure

To abutments of BNSF bridges

To the edge of BNSF crossings

To the closest start of BNSF curve (i.e. the distance from the spiral to the PSw/last long tie)

Basic property limits & railroad Right of Way lines

Graphical operating plan including but not limited to loading and unloading tracks, loop tracks, etc.

Include a description of work to be performed by BNSF. Example: “Construct 185 track feet including

a #11-141 lb. turnout from point of switch to clearance point, raise railroad pole line, adjust signals.”

Include a description of work to be performed by the contractor. Example: “Construct remaining

trackage from clearance point to end, place wheel stops, install plank crossing and signs, perform all

grading, install all drainage structures, install double switch point derail, provide electrical service to a

point opposite the proposed switch locations.”

Include a list of track materials to be used by the contractor. Example: “115-lb continuous welded rail

(CWR) on #4 new cross-ties, #11-115lb BNSF standard turnouts, 32-ft full depth timber crossing planks

to be placed in new construction.

Effective track capacities of proposed/modified tracks as measured from clear points and including any

necessary setbacks (derails, clearance points such as grade crossings, end-of-track, etc.)

For hazardous shipments, design follows AAR OT-55, “Recommended Railroad Operating Practices For

Transportation of Hazardous Materials”

Variances requested in writing in order to be approved. Only BNSF-approved variances to be shown on

conceptual layout. Submit approved variances with concept plans.

20

July 2023

30% Design Drawings Submittal Checklist:

30% checklist with conceptual checklist included

Track Plan alignment included

Dimension from proposed BNSF switch locations to an identifiable fix object in the field

(For practicality, shall be in the direction of the track)

Derail location stationing, left or right hand derail, and derail type

Crossing location(s) with stationing and width included

PC/PT stationing on all curves included

Curvature information on all curves included

14.21’ clearance point stationing included

Point of switch stationing included (PSw)

End of track stationing and structures included

Culvert/other pipe crossings included

Location of connection structures to existing drainage systems

Access roadway information called out

Turnout pad sizes called out

Turnarounds/Access at turnout pad determined

Track profile plan included

Vertical curves included

Vertical curves geometry (grade, length, PVC, PVI, PVT, rate of change, etc.)

Culvert/other pipe structures included on profile and cover & depth noted

Cover information on culvert/other pipe structures to top of subgrade & base of rail

BNSF construction coordination sheet for power turnout projects (One page blow up sheet of pad

size, signal house locations, key asset locations such as the derail and the signal locations)

Cross section drawings with typical sections, rail and ballast gradation(s) included

Grading limits plan

Survey monuments/control point locations

Utility relocates on the BNSF right-of-way with owner information

Utility relocates off of BNSF right-of-way with owner information

Separate sheet for each public crossing proposed / modified including information

Distance from turnouts to nearest crossings

Crossbucks locations / Lights & gates locations

Access roadway locations

Signal house locations (if applicable)

21

July 2023

Distance between multiple track crossings (if applicable)

DOT # (if crossing is existing)

Queuing distance from adjacent roadways (if applicable)

Contour information of surrounding terrain (use light gray lines for contours)

At least 300’ on each side parallel to the direction of the track

At least 100’ on each side parallel to the direction of the roadway

City, county, and governing roadway authority information

90% Design Drawings Submittal Checklist:

90% checklist with 30% checklist included

Clearance submittal for all structures coming within 15’ of the centerline of the closest track

Clearance submittal for all structures crossing above any track in the facility

Finalized drainage plan

Culvert extensions finalized

Culvert locations finalized with cover information requested in 30%

Line drawings for all pipe crossings/drainage structures under existing or proposed tracks

that will be impacted by the project

Pre-project drainage pattern with pre-project terrain contours

Post-project drainage pattern with (if available, include post-project terrain contours)

Finalized access roadway plan

Final turnout pad access routes

Final crossing locations internal to facility

Structure locations included (i.e. building sheds, catwalks, etc.)

H&H studies included in submittal (if required)

100% signed and sealed plans for structures included (Only structures that affects track stability or

track clearance will require reviews. E.g. pit plans, shed plans, catwalks, etc.)

Details for transitions between track sections (concrete, steel, industry, mainline)

22

July 2023

Final Track Plan / 100% Design Plan Submittal Checklist:

100% checklist with 90% checklist included

Signage plans included

Sign locations included

Lighting plan included

Details included

Switch geometry details

Stand details

Crossing details

Bumper details

Rail weights and tie specifications

Reference to the specifications within the BNSF design guidelines and applicable AREMA

guidelines

Culvert specifications

As-Built Record Drawing Submittal Checklist:

Lat/Lon of actual installed BNSF switch location

Actual installed location from an identifiable permanent structure in the field

Alignment deviations of actual installed track

Actual lengths of tracks and effective lengths of tracks

23

July 2023

5. Specifications for Construction of Industrial Trackage by Private Contractor

5.1 Contractor’s Responsibility: By acceptance of the contract the contractor assumes complete

responsibility for construction of the work. The Contractor should understand that any work not

specifically mentioned in the written specifications, but which is necessary, either directly or

indirectly, for the proper carrying out of the intent thereof, shall be required and applied, and will

perform all such work just as though it were particularly delineated or described. Contractor should

also understand that final approval of the track for service is the prerogative of BNSF and close

contact with BNSF's Engineering Representative is required. No work is to be performed on BNSF's

right-of-way, or in such proximity as to interfere with BNSF's tracks or roadbed, without advance

permission by BNSF, including insurance and if necessary, flagging protection.

5.2 Insurance Requirements: Contained within the Contract for Industrial Track Agreement to be

executed prior to construction.

5.3 Grading & Embankment: The work covered by this section of the specifications consists of

furnishing all plant, labor, material and equipment and performing all operations in connection with

construction of track roadbed, including clearing and grubbing, excavation, construction of

embankments and incidental items, all in accordance with the contract drawings and specifications.

The Contractor shall load, haul, spread, place and compact suitable materials in embankments and

shall finish the embankments to the grade, slope and alignment as shown in the plans. Suitable

materials shall consist of mineral soils free from organics, debris, and frozen materials. Embankment

slopes shall be compacted and dressed to provide a uniform and dense slope. Embankments shall

be built with approved materials from excavation of cuts or from borrow unless otherwise shown on

the plans.

If materials unsuitable for embankments (organics, debris, brush and trees, etc.) are encountered

within the areas to be excavated, or material existing below the designated subgrade in cuts or within

areas on which embankments are to be placed are of such nature that stability of the roadbed will

be impaired, such materials shall be removed and wasted or stockpiled for other use. Topsoil

removed from embankment areas shall be spread uniformly over the embankment slopes.

Unsuitable material removed from embankment foundations or below subgrade elevation in

excavation areas shall be replaced to grade with suitable material compacted as specified for

embankments in these specifications.

Wherever an embankment is to be placed on or against an existing slope steeper than four horizontal

to one vertical (4:1 slope), such slope shall be cut into steps as the construction of the new

embankment progresses. Such steps shall each have a horizontal dimension of not less than three

feet and a vertical rise of one foot.

At all times, the Contractor shall operate sufficient equipment to compact the embankment at the

rate at which it is being placed. Compaction shall be accomplished by sheep’s foot rollers,

pneumatic- tired rollers, steel-wheeled rollers, vibratory compactors, or other approved

equipment. Use construction procedures and drainage design that will provide a stable roadbed.

24

July 2023

Each layer in embankments made up primarily of materials other than rock shall not exceed 6" in

loose depth and shall be compacted to the dry density as specified hereinafter before additional

layers are placed. All embankments shall be compacted to a density of not less than 95% of the

maximum standard laboratory density, and not more than +4 percentage points above the optimum

moisture content, unless otherwise specified on the drawings. The standard laboratory density and

optimum moisture content shall be the maximum density and optimum moisture as determined in

accordance with ASTM Designation: D 698 (Standard Proctor Test). Copies of soil test results shall be

furnished to owner.

On top of the embankment fill, the Contractor shall place a minimum of 6 inches of granular sub-

ballast which meets the above criteria and contains no material larger than that which will pass

through a (3) inch square sieve. Sub-ballast shall be crushed gravel or crushed stone with a minimum

75% of the material having two fractured faces. Sub-ballast must meet the quality requirements of

ASTM Designation: D 1241 and be approved by the Engineer. Additional sub-ballast may be required

as determined from an engineering soil analysis.

5.4 Culverts: The minimum diameter for all culverts installed under main tracks or tracks maintained by

BNSF is 36 inches. This is to accommodate regular inspection and cleaning. Culverts maintained by

the Customer should be 24 inches or larger. Impacts to existing culverts shall be included in the

customer’s scope of the project.

Culvert extensions with a change in direction or a change in pipe section (including size) is generally

not permitted. If the project involves removing/abandoning existing culverts under BNSF tracks,

adding additional culverts under BNSF tracks or extending an existing culvert under BNSF tracks, a

hydraulic study shall be provided to demonstrate that the post project condition will meet or exceed

the existing hydraulic capacity. Projects adjacent to BNSF right-of-way with potential hydraulic

impacts to BNSF will also require a hydraulic study. The hydraulic study can be waived if the project

area is less than 1.0 Ac and does not have any hydraulic impact to an existing BNSF bridge/drainage

structure.

Existing pipes that have to be extended will become the responsibility of the customer in installation,

ownership and maintenance. If it is determined by BNSF Structures that an existing pipe cannot be

extended in an acceptable manner, the cost of installing an acceptable replacement pipe shall be

the responsibility of the customer. Additional guidelines related to pipe installations can be

requested from your BNSF engineering project representative.

5.5 Corrugated Metal Culverts: These instructions cover the selection, installation, and fabrication of

circular type zinc coated (galvanized) corrugated steel culverts for nominal diameters of 36-inch to

96-inch, inclusive. Additional protective coatings may be specified or allowed by BNSF Engineering.

Galvanized corrugated steel pipe shall be manufactured in accordance with AASHTO Specifications

M 36 and M 218. All areas of surface rust on re-corrugated ends or lock seams shall be painted using

the hot-dip or metallizing process.

Design, installation, and fabrication shall be in accordance with current American Railway

Engineering and Maintenance of Way Association (AREMA) Specifications Chapter 1, Part 4,

Culverts. Additionally, all culvert pipes shall meet the requirements shown in Table 1.

25

July 2023

TABLE 1

Nominal

Diameter

(Inches)

Nominal*

Corrugation

(Inches)

Minimum**

Width of Lap

(Inches)

Nominal

Thickness

(Inches)

Thickness

U.S. Std.

Gage

Rivet**

Diameter

(Inches)

Max.

Cover

Min.

Cover

36

2

-

2/3 x 1/2

2

0.109

12

3/8

40'

***

42

2

-

2/3 X 1/2

3

0.138

10

3/8

70'

***

42

3 x 1 &5 x 1

3

0.109

12

7/16

70'

***

48

2

-

2/3 x 1/2

3

0.138

10

3/8

65'

***

48

3 x 1 & 5 x 1

3

0.109

12

7/16

70'

***

54

2

-

2/3 x 1/2

3

0.168

8

3/8

60'

***

54

3 x 1 & 5 x1

3

0.138

10

7/16

75'

***

60

2

-

2/3 x 1/2

3

0.168

8

3/8

55'

***

60

3 x 1 & 5 x 1

3

0.138

10

7/16

70'

***

66

3 X 1 & 5 X 1

3

0.138

10

7/16

60'

***

72

3 X 1 & 5 X 1

3

0.168

10

7/16

65'

***

84

3 X 1 & 5 X 1

3

0.168

8

7/16

55'

***

96

3 X 1 & 5 X 1

3

0.168

8

7/16

45'

***

* Where two types of corrugation are acceptable, the use of standard 2-2/3" x 1/2" material is

preferred, if available. 5 x 1 corrugations to be used only on helical pipe.

** For riveted pipe.

Pipes 48 inches or greater in diameter shall be shop-elongated 5 percent of their diameter in a vertical

direction and have lifting lugs.

*** Minimum cover to be one-half diameter of culvert pipe from top of subgrade to top of pipe.

Due to settlement of culvert pipes, cambering longitudinally is recommended to improve the flow

line profile after settlement. This is accomplished by laying the upstream half of the pipe on a flatter

grade than the downstream half. Riveted pipe shall be placed with the inside circumferential laps

pointing downstream and with the longitudinal laps at the side. Pipes shall be installed with a camber

suitable to the height of the cover over the pipe and bearing capacity of the supporting soil.

Firm support must be provided to obtain a satisfactory installation. The filling material adjacent to

pipes shall be loose granular material, free from large stones, frozen lumps, cinders, or rubbish. The

filling shall be deposited alternately on opposite sides of the pipe in layers not exceeding 6 inches

in depth, and each layer shall be thoroughly tamped before placing the next layer. Special care shall

be taken in tamping under the lower part of the pipe. For a trench installation, the backfill shall be

tamped the entire width of the trench, and for surface installation it shall be tamped not less than

one half the pipe diameter out from the sides of the pipe. The density of the backfill after tamping

must be at least 95% of its maximum density, as determined by ASTM D 698.

Any other type or size drainage structure shall have approval of BNSF Engineering prior to

installation under track locations.

5.6 Utility Crossings: Utility crossings and relocations shall conform to BNSF standards as outlined in

the "BNSF Utility Accommodation Policy" (https://www.bnsf.com/bnsf-resources/pdf/about-

bnsf/utility.pdf). Applications for utility crossings and relocations are handled by Jones, Lang, LaSalle

(JLL), phone number 1- 866-498-6647. Any questions regarding utilities can be directed to the BNSF

Engineering representative.

26

July 2023

5.7 Curvature and Grades: Tracks will be staked by the customer’s surveyor (under flag protection if

necessary) and constructed as shown on the approved plans. Any changes to the approved design

need to be reviewed by BNSF Engineering or appointed representative.

5.8 Clearances: BNSF will adhere to the "Clearance Requirements By State," BNSF Dwg. No. 2509, Sheet

No. 2 (see Appendix, page A-44) for each state. If a state does not have its own clearances, the

"BNSF Minimum Clearances Diagram," BNSF Dwg. No. 2509, Sheet No. 1 (see Appendix, page A-

45) will apply. Side clearances for curves should have an additional 1-1/2" per degree of curvature.

Warning signs will be installed for all close clearances less than standard (see Appendix, page A-46).

All loading/unloading equipment that fouls the clearance envelope during operation must positively

lock in a non-fouling position when not in use.

5.9 Material: BNSF's Division Engineer representative should inspect all track materials prior to

placement to avoid removal of sub-standard material. BNSF personnel will also inspect the track

before placing it into service.

5.9.1 Rail: For trackage maintained by the Customer the minimum acceptable rail shall be 112#

section (5-1/2” base) and shall be compatible with BNSF standard rail section. For locations

where trackage will be maintained by BNSF rail and fastenings shall conform to the BNSF

standard rail section in use in that area. Contractor shall contact BNSF Engineering for

approved section. Transition rails or compromise joints at the BNSF-Customer interface are

the responsibility of the customer. Minimum length shall not be less than 39 feet except in

turnouts and shall be free from defects. Rail should be minimum full ball relay rail, not

exceeding 3/16-inch wear on any surface. Continuous welded rail (CWR) will need to be de-

stressed as soon as possible after laying (see “Procedures for the Installation, Adjustment,

Maintenance, and Inspection of CWR in Industry Tracks” Appendix, page A-1 thru A-11).

CWR is recommended when using concrete ties. Thermite and flash-butt welds must be

placed in crib area between ties. An abrasive rail saw will be used to cut rail—no torch-

cutting.

5.9.2 Anchors: Rail anchors shall be new or reconditioned, sized to fit the rail section, and shall

be provided per industrial track design criteria on pages 3 and 6. High traffic volumes or

unusual grade or alignment problems may require additional anchors as determined by BNSF

Engineering. Turnouts shall also be anchored.

5.9.3 Ties: Hardwood ties shall be new 7” X 8” (AREMA No. 4) or 7” X 9” (No. 5), 8’-6” long, placed

on 21.5" centers. Switch ties shall have a minimum cross section of 7" x 9" and minimum

lengths shall conform to applicable BNSF Standard plans. Concrete ties shall be pre-

stressed, measure 11” wide at the bottom and 9” high with a length of 8’ 3” and weight of

630 pounds. Concrete ties can be placed on 28” centers provided there is a minimum ballast

section of 8” below the tie. Second-hand, or “3/4” concrete ties can be used after inspection

and approval from the BNSF Roadmaster. When placing 3/4 ties, the damaged shoulders

should be alternated from left to right sides so that they are not on the same side. Steel ties

are spaced at 24” centers with 8” ballast section and can be used with timber or concrete

ties. Steel ties should not be used within 200 feet of a signal circuit identified by insulated

joints.

5.9.4 Turnouts (Switches, Frogs & Guardrails): For Customer installed, owned and maintained

turnouts, all parts shall be new or good secondhand, with secondhand parts being free of

injurious defects.

27

July 2023

5.9.5 Tie Plates: Tie plates may be new or secondhand, free of injurious defects and foreign

material, conforming to AREMA Specifications, and shall fit rail being used. For rail 110#

section and greater, all plates will be double-shouldered.

5.9.6 Joints: New or secondhand joints, free of foreign material and without injurious defects,

and with 4 or 6 bolt holes, conforming to AREMA requirements, may be furnished to fit rail

section for which they are designed. Bolt holes must be drilled with proper equipment.

Torch-cutting of bolt holes is not allowed. New or secondhand compromise joints of

manufactured type (welded or homemade are not acceptable), free of foreign material and

without injurious defects, shall be furnished and used where rail section (weight or design)

changes. Rail section by weight shall not be compromised where difference in weight is in

excess of 25 lbs. When this becomes necessary, a rail of some weight between the two

different rail sections, in excess of 25 lbs., shall be used and the compromise made in two

steps. The length of the medium-weight rail should be 39 feet where practical.

5.9.7 Spikes: 5/8" x 6" cut track spikes shall be installed. All spikes shall conform to AREMA

requirements.

5.9.8 Track Bolts & Nuts: Track bolts and nuts shall be installed conforming to AREMA

Specifications. Bolts will be correct size and length to fit rail.

5.9.9 Lock Washers: One lock washer conforming to AREMA Specifications shall be installed on

each track bolt.

5.9.10 Ballast: Track ballast shall be BNSF Class 2 (AREMA Size 5) (1" - 3/8") unless a variance

request is reviewed and approved by BNSF Engineering. For steel ties, AREMA Class 4A

ballast may be used under the tie where required by the tie manufacturer. Ballast shall be

free from loam, dust, and other foreign particles and shall not have less than 75% crushed

particles with two or more fractured faces, unless otherwise approved by BNSF. Processed

ballast shall be hard, dense, of angular particle structure, providing sharp corners and

cubicle fragments and free of deleterious materials. Ballast materials shall provide high

resistance to temperature changes, chemical attack, have high electrical resistance, low

absorption properties and free of cementing characteristics. Materials shall have sufficient

unit weight (measured in pounds per cubic foot) and have a limited amount of flat and

elongated particles. Unless it meets or exceeds BNSF requirements, slag is not an approved

ballast material. Walkway ballast shall be BNSF Class 2 (AREMA Size 5) (1" - 3/8").

SIZE NO. SQ.

OPENING

PERCENT PASSING

2 ½” 2” 1 ¾” 1 ½” 1 ¼” 1" 3/4” 1/2” 3/8” No. 4

BNSF Class 2

(AREMA Size 5)

1” – 3/8”

100

90-100 40-75 15-35 0-15 0-5

5.9.11 Bumping Post: An earthen berm (see Appendix, page A-17) or suitable bumping post,

approved by the Railroad, shall be installed at the ends of tracks. Also, a red retro-reflective

marker shall be placed at the end of track. Cars shall not be parked or spotted closer than

25 feet to the end of the track.

5.9.12 Derails: A derail shall be placed on all tracks connecting with a main line, siding, or industrial

lead. Derails protecting mainline tracks and controlled sidings shall be double switch point

28

July 2023

or sliding derail with crowder (see BNSF Standard Plans 2400 and 2405) and installed so that the

derailed car is directed away from BNSF trackage. Use of sliding derails must be approved

by the Division GM. A power derail is required when the mainline turnout is powered, and

BNSF will install track and signal from the point of switch to the insulated joints just beyond

the power derail. Derails protecting mainline tracks shall be placed a minimum of 100 feet

behind the 14' clearance point and placed on tangent track where possible. Derails

protecting other-than-mainline tracks shall be placed a minimum of 50 feet behind the 14'

clearance point and placed on tangent track where possible. The type of derail and actual

location may be determined by BNSF Operating Department requirements. A “Derail” sign

needs to be placed next to the derail. Timber ties are recommended within 50 feet of a

derail.

A second derail may be required where BNSF locomotives are parked during unit train

loading operations. BNSF's Operating department will determine the necessity and type.

If required, placement will be 275 feet from first derail. A “Derail” sign needs to be placed

next to the derail.

5.9.13 Highway Crossings: All crossings shall be approved by BNSF Engineering and local

governments as to type and design, in advance of placing order. Effect on sight distance of

crossings must be considered when planning construction of trackage in vicinity of public

grade crossings not equipped with automatic signals.

5.9.14 Under Track Hoppers or Pits: Plans shall be approved by BNSF Engineering or authorized

representative. Specifications for unloading pits are covered in the "AREMA Manual for

Railway Engineering," (Chapter 15, Section 8.4). Gratings covering open pits must be bolted

in place.

5.10 Track Construction

5.10.1 General: All work shall be of good quality in materials, equipment and workmanship and

shall conform in every respect with the specifications and instructions.

5.10.2 Ties: Ties will be unloaded and handled in such a manner as not to damage ties, using

approved handling equipment. Ties to be placed at design spacing of 21.5-inch center to

center (22 ties/39 feet) for wood, and 28-inch centers for concrete, on the finished

subgrade, perpendicular to center line of track with the right-hand ends of ties being parallel.

Exception: On curves, align the ties to the inside of the curve. All joints are to be suspended

between ties. Top surface of ties shall be clean and smooth to provide full bearing for tie

plates. Lay wood ties with heartwood face down, and if not possible to determine position

of the heartwood, lay the widest surface of the tie down. If spikes are pulled from any tie,

hole shall be filled by driving in a treated wood tie plug the full depth of the hole. Boring or

adzing of ties shall be kept to a minimum.

5.10.3 Tie Plates: Double-shouldered tie plates will be used on all ties and set in position with cant

surface sloping inward, making sure they are firmly seated and have full bearing. After rails

are in place, shoulder of plates shall be in full contact with outside edge of rail base.

5.10.4 Rails: Assemble joints before fastening rails to ties, using joint bars with full number of track

bolts and spring washer for each bolt, first removing loose mill scale and rust from contact

surfaces or joint bars and rails. In laying secondhand rail, care must be taken to rail end

mismatch at the joints. Under no circumstances must rail be struck in web with tool or any

metal object. The right-hand rail facing in direction of increasing construction shall be spiked

29

July 2023

to ties, and the opposite rail shall be brought to gage of 4' 8-1/2", measured at right angles

between the rails, in a place 5/8" below top of rail. A track gauge manufactured for the

purpose of measuring gage should be used rather than a tape measure. Gage is to be