Electric Fencing 0

Electric Fencing Systems Design, Installation

& Maintenance

2

Electric Fencing 101

Contents

Disclaimer: While every effort has been made to ensure accuracy,

neither Gallagher Group Limited or any employee of the company will be

liable on any ground whatsoever to any party in respect of decisions or

actions they may make as a result of using this information.

In accordance with the Gallagher policy of continuing development,

design and specifications are subject to change without notice.

Why Use Electric Fencing?

Getting Started

Powering Your Fence

Fence Construction

Permanent Fencing

Offset Fencing

Temporary & Portable Fencing

Fault Finding

Safety

Troubleshooting

04

08

09

19

20

32

34

42

44

50

5

4

NZL Cattle

3. Animal receives shock when it touches the fence.

1. Energizer (power) is connected to the fence and the ground.

2. Power is sent along the fence in pulses.

Why Use Electric Fencing?

A short, safe and memorable shock to create a psychological as

well as a physical barrier.

Why Use Electric Fencing?

How Electric Fencing Works

• Keeping domestic animals in

• Keeping wild animals out

• Separating different groups of animals

• Rationing of crops and pastures

• Fencing off eroding areas, trees, rivers and roads

At a basic level electric fencing is more effective at containing domestic

animals livestock/excluding wildlife than traditional fencing due to the fact

that the short, safe and memorable shock creates a psychological as well as a

physical barrier.

A pulsed electric current is sent along the fence wire, about one pulse per

second, from an energizer which is grounded. When the animal touches the

fence it completes the circuit between the fence and the ground receiving a

short, sharp - but safe shock. The shock is memorable enough that the animal

never forgets.

An electric fence is a psychological barrier, so it doesn’t need great physical

strength. However, it must be well designed and constructed to absorb some

pressure from animals, snow and wind. The energizer must have enough power

for the length of fence and for the animals being controlled.

Electric fencing is a reliable, cost effective way to control animal movement

and manage pasture. This includes:

7

6

KEY BENEFITS

Effective

Maximize results potential of feed and

greatly improve the feed quality and

yield.

Efficient

Direct harvesting of grass or fodder

crops by the animal with manure

returned directly to the soil during the

process.

Flexible

Use a combination of permanent &

portable fencing to maximize grazing

area control.

Beyond just keeping animals in and

out, electric fencing is the best way

to achieve optimum pasture yield

using rotational grazing methods.

This approach works by keeping

the grass fresh, short and palatable

which ultimately leads to increased

meat and milk production as well

as reduced supplemental feed

costs. It involves grazing paddocks

in rotation using a combination of

permanent and/or temporary fenced

grazing areas.

Pasture Management and Rotational Grazing

KEY CONSIDERATIONS

Achieving optimum pasture growth is

a delicate balance. When considering

how best to meter out the pasture feed

available look at the following:

1. Number & size of grazing areas -

grazing specific areas, so other pasture

sections are able to rest and re-grow.

2. How many animals to put on that

grazing area - efficiently grazing the

allocated area.

3. And for how long – graze to desired

residual grass height

The combination of these factors

determines the rotation length (how many

days before the first area in the rotation

is grazed again). The optimum rotation

length varies significantly depending on

the geographical location and time of

year.

The more regular the shift (preferably

daily or every few days) the more time the

pasture spends growing rather than being

grazed, leading to greater grass growth

and stock carrying capacity.

Where a permanently fenced paddock is

further subdivided using portable electric

fences the stock are contained by both

a front and a back fence. The back fence

protects the recently-grazed area to allow

it to recover so it can be grazed again

sooner.

Subdivision with high stocking density

ensures grass is harvested down evenly

to the optimum residual length, and that

over time manure is spread more evenly

over the whole grazing area.

Why It Works

Maintaining grass at the high growth

tilling stage ensures young, lush,

green pasture with high protein and

energy levels. Grazed and rested for

the right amount of time creates the

ideal conditions for grass growth

when the plants produce leafy shoots

from the base.

There are various grass varieties to suit

different environments. Longer term

options last 10 years or more and shorter

term annuals can give extra yield over a

shorter time-frame.

Forage crops (i.e. turnips, kale, sorghum

etc.) are low cost to establish and can be

used to fill feed deficits during cold and/

or dry months where grass growth slows

or stops altogether. Direct grazing of

such crops using portable electric fencing

eliminates harvesting and feeding out,

with animal waste being returned directly

to the land.

If you farm sheep intensively, you may

want as many as 100 paddocks. This

means the sheep can be moved daily

onto a fresh paddock using a three month

rotation during slow or zero growth

periods. When there are lambs and ewes

during spring, two or more flocks can be

grazed on a faster rotation.

For beef and dairy producers 30–50

paddocks are usually enough. Cattle are

easy to strip graze with only one wire when

longer rotations are necessary during slow

growth periods.

Managed Grazing Examples

Why Use Electric Fencing? Why Use Electric Fencing?

9

8

Getting Started

Every electric fence system is made up of a:

• Power System

• Fencing System

Selection of these depends on property size, fencing usage and animal type.

Power System

Fence System

1. What do you want to achieve with

your fencing?

• Determines permanent and/or

temporary subdivision

2. How long do you want it to last?

• Some products are designed to

last well over 10 years others while

others are warranted under 10

years

3. What animals are you trying to

keep in/out?

• Influences the fence setup like the

number of wires & spacing

• Impacts product choice. For

example, horses have special

requirements

1. Do you have a reliable power

source?

• Will determine Energizer type –

110v or battery (including solar

options)

2 How much fencing are you looking

to power?

• Distance influences Energizer size –

and fence construction

3. What is your location?

• Grounding is critical to good power

transfer, drier areas need different

fencing set-ups and more grounding

to compensate

• Solar energizer options are perfect

for remote locations with good

sunshine

Energizers

All Gallagher Energizers are low-

impedance and guarantee a high-energy

pulse. Selection is based on power

availability, fence length, number of wires,

vegetation touching the fence, application

(does it need to be regularly moved) and

the number of animals (fence pressure).

The only true way to compare different

Energizers is based on STORED JOULES,

it is a constant measure and not affected

by variations in fence conditions or

grounding.

Stored Joules – How it works

Like horsepower on a vehicle. It is the

potential power in the engine to maintain

speed no matter what the vehicle is pulling

behind, or what the gradient of the road is.

In an Energizer, power from either a 110V

outlet or battery source enters the unit

and is stored in capacitors. This stored

energy is the potential power available

in the single pulse per second generated

when the animal touches the fence. The

higher the stored joule rating the greater

the Energizer’s ability to push past shorts

caused by weeds and fence faults and

maintain fence voltage, as well as cover

future fence expansion.

Gallagher Recommends Always

purchase the highest powered

Energizer you can afford. More

power provides more confidence

that the fence will perform despite

unexpected shorts like vegetation

growth. Also electric fence systems

tend to grow, so purchase an

Energizer with headroom to power

additional future fence.

Powering Your Fence

Energizer Selection

TERMS

Voltage - a measure of electrical

‘pressure’ that drives current flow

Current (amps) - a measure of the

flow of electrical energy

Stored Joules - the amount of

energy stored in the energizer

available for each pulse

Output Joules - the energy

discharged on the fence for each

pulse

Pulse Shape - the shape of the wave

of energy traveling down the fence

line

Gallagher’s range of Energizers

continues a proud tradition of the

world’s best engineered products

1) Indicator lights on all Energizers

tell you at a glance that the

Energizer is operating

2) All energizers are fitted with

lightning protection and are fully

modular for rapid servicing and

replacement

3) Gallagher’s reputation for

worldwide service and satisfaction

has endured for over 80 years

4) All Energizers purchased after

January 1, 2018 carry a three year

warranty.

11

10

Powering Your Fence

Energizer Selection

Types of Energizers

110V, Plug-in Energizers are the best

choice if you have access to a power outlet.

The Energizers are reliable in every situation

with exception of a power outage and will

provide you with the most power for the least

about of money. You will need to install them

inside a structure where they are protected

from moisture.

Battery Energizers are typically portable

and great for remote areas far from power

outlets especially in cases where they are

periodically moved. These are powered by a

12v rechargeable battery, “D” cell batteries

or a 9 volt disposable dry cell battery.

Solar Energizers are portable and an

excellent choice for temporary fence

applications. They are a logical choice

for remote areas where there is no 110V

outlets. While they have the highest upfront

cost per joule, the power to operate them is

free as long as they have adequate sunlight.

The solar panel charges the battery by

converting light directly into electricity. The

battery stores this electricity to operate

the energizer. This enables the energizer

to operate at night or during periods of low

sunlight.

Multi Powered Energizers combined with

various adaptors will allow you to power

your Energizer using any one of the methods

listed above: 110V Outlet, Battery or Solar.

This is a great choice if you move your fence

to locations where 110v power will exist and

other locations where it is not available.

Powering Your Fence

Energizer Selection

Gallagher Recommends – comparing on stored joules only, since these distance/acreage ratings are

always manufacturers estimates because two properties of the same acreage/fence distance may

have dramatically different conditions e.g.: number of wires, vegetation growth, stocking intensity.

STORED

JOULES

‘UP TO’

DISTANCE

CLEAN FENCE

(MILES/ACRES)

RECOMMENDED

DISTANCE

TYPICAL FENCE

(MILES/ACRES)

I SERIES

OPTION

LIVESTOCK CONTROLLED

M10000i 100.0 1,000 / 6,000 125 / 3,000

•

M5800i 58.0 430 / 2,700 87 / 2,200

•

M1500 15.0 160 / 900 40 / 360

M1100 11.0 110 / 650 36 / 280

M800 8.0 90 / 520 30 / 200

M560 5.6 75 / 400 23 / 130

M360 3.6 55 /250 19 / 95

M160 1.6 30 / 100 11 / 60

M120 1.2 15 / 60 6 / 30

M60 0.6 10 / 40 3 / 20

M30 0.3 5 / 20 2 / 10

M10 0.1 2 / 10 0.5 / 3

MBS2800i 28.0 250 / 1,500 50 / 1,000

•

MBS1800i 18.0 200 / 1,200 42 / 420

•

MB1000 10.0 100 / 600 34 / 250

MBS800 8.0 90 / 520 30 / 200

MBS400 4.0 60 / 280 20 / 120

MBS200 2.0 45 / 160 14/90

MB150 1.5 30 / 100 11 / 60

B60 0.6 15 / 60 5 / 40

B11 0.11 4 / 20 0.6 / 6

B10 0.1 4 / 20 0.6 / 6

S400 4.0 60 / 280 20 / 120

S200 2.0 45 / 160 14 / 90

S100 1.0 30 / 100 8 / 60

S40 0.4 25 / 80 5 / 30

S20 0.20 12 / 40 2 / 14

S16 0.16 10 / 30 1 / 10

S10 0.1 3 / 15 0.5 / 5

ALL IN ONE SOLAR

MULTI-POWER

110 VOLT

BATTERY

13

12

i

Powering Your Fence

i Series Fence System

Powering Your Fence

i Series Fence System

ALARM SYSTEM

Secure your

assets

The i Series Energizers have extremely reliable power that adapts output up or down

depending on your fence conditions. Each one also comes with a separate controller that

can be mounted outdoors for easy fence performance checks.

3

2

2

4

1

5

2

5

Once the fault is repaired, power is

restored to the fence and tested using

the Remote.

ON

OFF

Power to the fence at the fault location

is turned off using the Remote, allowing

a safe and convenient repair.

4

Fence Monitor(s) recognize any

significant drop in fence zone or

Energizer performance and raise alarms.

1

Alerts are sent to the Energizer

Controller and/or optional Alarm System.

2

3

The Controller and Remote indicate

which zone is in fault. The Remote is

used to find the fault within the zone.

Quickly locate

and repair faults

ENERGIZER REMOTE & FAULT FINDER

i Series Fence Energizer Systems

Create fence

zones and

monitor fence

performance

around your

property

FENCE MONITOR

ENERGIZER CONTROLLER

Easily monitor

and control fence

performance

ENERGIZER

Reliable and

adaptive

performance

even in extreme

conditions

How the System Works:

On i Series models you can also add

monitors around the fence line that

feed information back to the

Controller and tell you if all is well or

if there is a fault in their area.

The Remote & Fault Finder helps

pinpoint any faults quickly, saving

hours hunting for and fixing the

issue.

15

14

Energizer Size Required Ground Rods

Up to 15 Joules 3 Rods minimum

Up to 28 Joules 6 Rods minimum

Up to 58 Joules 12 Rods minimum

Handy Hint

Grounding Systems

The ground must be as conductive as possible for the fence to give the animal an

effective shock. A simple guide is one ground rod for every five joules of stored

energy with a minimum of three ground rods.

Additionally you will need to setup your electric fence according to how ‘green’ the

area is all year round.

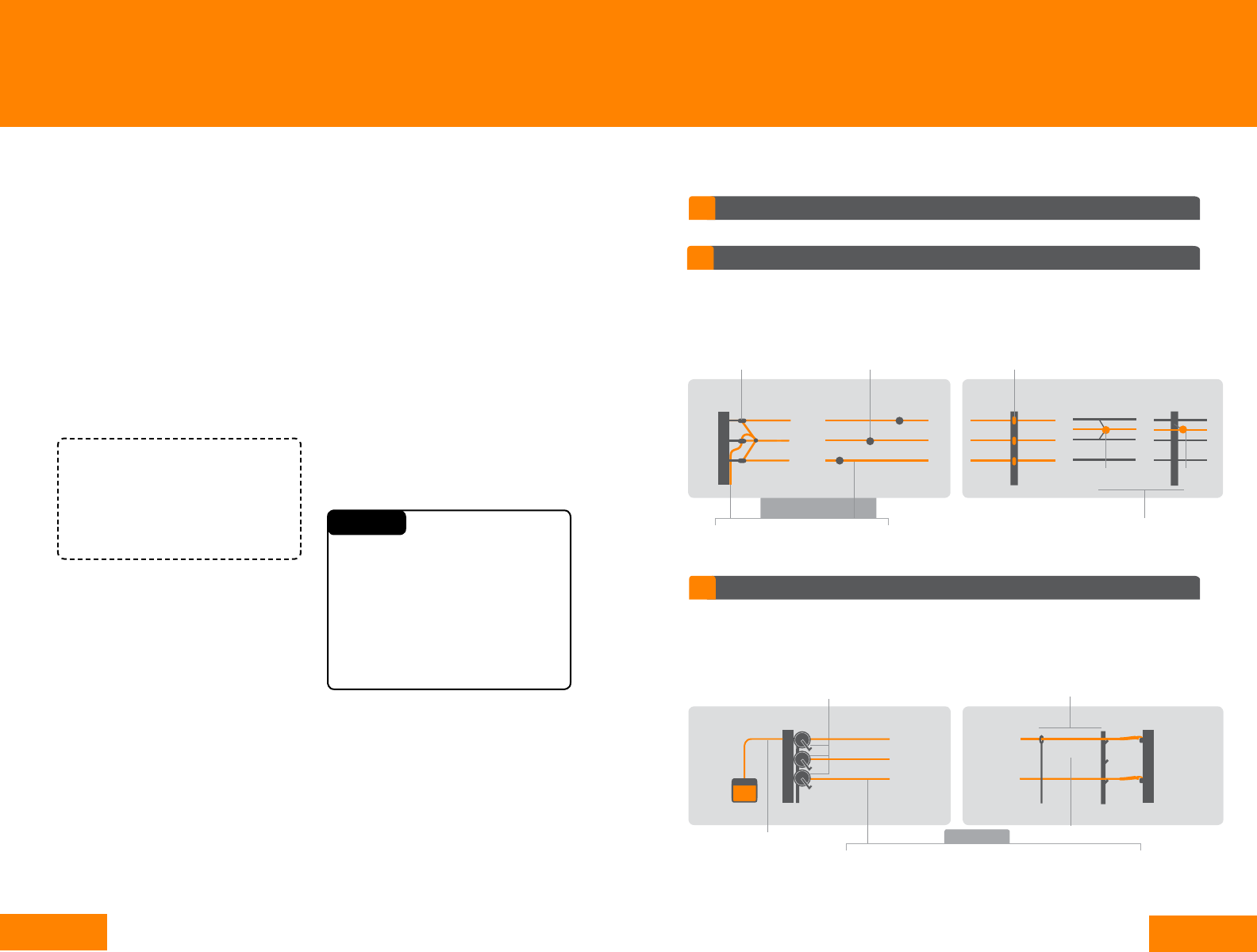

All Live Wire System

– best suited for wetter regions

For use in greener regions with

good ground conductivity. All

fence wires connect to the red

terminal on the Energizer and a

shock is delivered to an animal

when it’s touching the ground

and the fence at the same time.

Ground Return Wire System

– best suited for drier regions

For use where the ground

struggles to conduct enough

power (for year-round dry, frozen

or snow conditions). The live &

ground wires on the fence

create the shock when the

animal touches them both at the

same time.

Don’t Do

Allow bare wires to touch an iron clad

building - use double insulated cable

Keep energizer ground system 33-40’ away

from other electrical ground connections

Do not use rebar for ground rods

Keep energizer ground system 33-40’ away

from any metal pipes carrying water

Do not use copper lead-out wire

or copper ground rods.

Use galvanized ground rods. Rusty or

corroded ground rods will not be effective

Place near fertilizer, animal urine and

manure (corrosion)

Locate rods where soil tends to stay moist,

north sides of buildings, low spots

Place your ground rods where they are

likely to be hit by equipment

Use high conductive cable for connecting the

Energizer to the ground system and fence

When constructing ground return wire fences,

re-ground negative wires with a ground rod

every 1,200’

i

Powering Your Fence

Grounding

Powering Your Fence

Grounding

The rule for ground rods when installing permanent fencing

10’ Between ground rods

3 Ground rods minimum

Grounding

Live Fence

6’ Minimum length of rods

1 Wire connecting all rods to Energizer ground terminal

As a rule of thumb, use at least 3 ground rods or the Energizer Stored Joules rating

divided by 5.

Grounding

Live Fence

Follow the recommendation in the chart

to get the maximum benefit. When in

doubt, add more ground rods. The number

of ground rods will vary depending on

the power of the energizer and the soil

type. High powered energizers need more

ground rods than low powered energizers.

Dry, sandy, rocky or frozen soil will require

more ground rods than wet soils.

Why does the Energizer need a ground

system?

The ground is half the circuit of your

fencing system. Electrons travel from

the energizer, along the fence wires

and back through the ground to the

Energizer to complete the circuit. Like a

radio antenna collects sound waves, the

ground system collects the electrons.

The ground must be as conductive as

possible for the fence to give the animal

an effective shock.

Main causes of a poor ground

system are:

• Rusty or corroded ground rods

• Broken ground wire connecting

the rods

• Not enough ground rods

• Ground rods too close together

or too short

• Poor connections at the rod or in

the connecting wire

17

16

i

Powering Your Fence

Basic Fault Finding

Powering Your Fence

Testing Your Power

This should be done once a short section

of fence has been built. You should test

your system at least once a year at the

height of any dry period to ensure the

grounding capacity is sufficient for the

joule rating of the energizer.

Short the fence out at least 330’ away

from the ground system by using several

ground rods between the wires and the

ground. Reduce the fence voltage at this

point to 2000V (2kV) or less.

Using a Volt Meter, measure the voltage

between the wire connecting through

the ground rods to the Energizer ground

terminal and an independent ground rod.

This rod should be a galvanized metal

rod, minimum 8” long. Place the rod 3’

away from the ground rods or as far away

as your Volt Meter cable will reach.

There should be no reading on the Volt

Meter; however, up to 200V (0.2kV) is

acceptable. If the voltage is higher than

this, switch off the Energizer, drive in

more ground rods at the recommended

spacings and connect them to the

existing ground system until the voltage

is down to the acceptable level.

Testing on All Live Wire Ground System

Install a 6’ ground rod as close a possible

to the end of the fence. Install a 500

ohm load tester between a hot wire and

ground wire. Choose the location for the

ground rod in a damp area if possible. If

you cannot find a damp area, the ground

test may be unreliable.

Using a Volt Meter, measure the voltage

between the hot wire and the ground wire

across the load tester you just installed.

Next measure the voltage between the

hot wire and the independent ground rod,

leaving the load tester in place.

If the second voltage reading exceeds

the first by more than 1000V (1kV)

check the ground return wire for loose

connections.

Finally, connect the independent ground

rod to the ground return wire as a

permanent connection.

Extra ground rods can be added at

various places around the fencing system

and connected to the ground return wire

to improve ground performance.

If the first voltage reading is less than

3kV, your fence system is at risk of poor

animal control.

Assuming that your ground wire return

checked out satisfactorily, check that the

fence hot wire has good connections. If

connections are good, it is possible that

your energizer is too small for your fence

system. Assess your total length of fence

or property size against the energizer

selection chart on page 11.

Testing a Ground Return Wire System

The current flow on the fence will vary

depending on the size of your Energizer,

amount of vegetation and the size of

your fence system. With time you will

learn the normal current flow on your

fence.

Fence tools and testers are another

useful accessory to have on hand when

building, maintaining or checking an

electric fence. Gallagher has two fence

testers, both available from your local

Gallagher Dealer. The Fault Finder is a

all-in one device, current meter and fault

finder. The Volt Meter measures volts

only.

To obtain the best results from your Fault

Finder, Gallagher recommends that you

check the current while the fence is

opererating without any faults. Then,

when you suspect there is a fault on the

fence line, you can compare the current

flow with the “normal” current flow.

This will indicate whether a fault exists

and, if so, how much the fault is affecting

the performance of the fence.

1. The Arrow on the LCD will indicate

which direction the current is flowing.

2. Following the direction of the current,

take readings approx. every 330’ or at

junction points along your fence line.

Note: At a junction point, follow the wire

with the highest current flow.

3. A fault is indicated by a drop in current

flow between two checkpoints. The fault

will be somewhere between the two

checkpoints.

4. To narrow down location of the fault,

work back along the fence checking the

current flow at shorter intervals.

5. Correct the fault.

6. After correcting the fault you should

see the current reading drop and the

voltage group. If not, check for

further faults.

See page 50 for more troubleshooting help

using a Fault Finder.

Multi-wire fences connected in parallel will have similar current flowing in each

wire. To get the total fence current flow, add together the current flow in each

wire.

HANDY HINT:

Using a Fault Finder

Fence Volt Meter

G503014

Fence Volt/Current

Meter and Fault Finder

G50905

19

18

i

Powering Your Fence

Lightning Protection & Leadouts

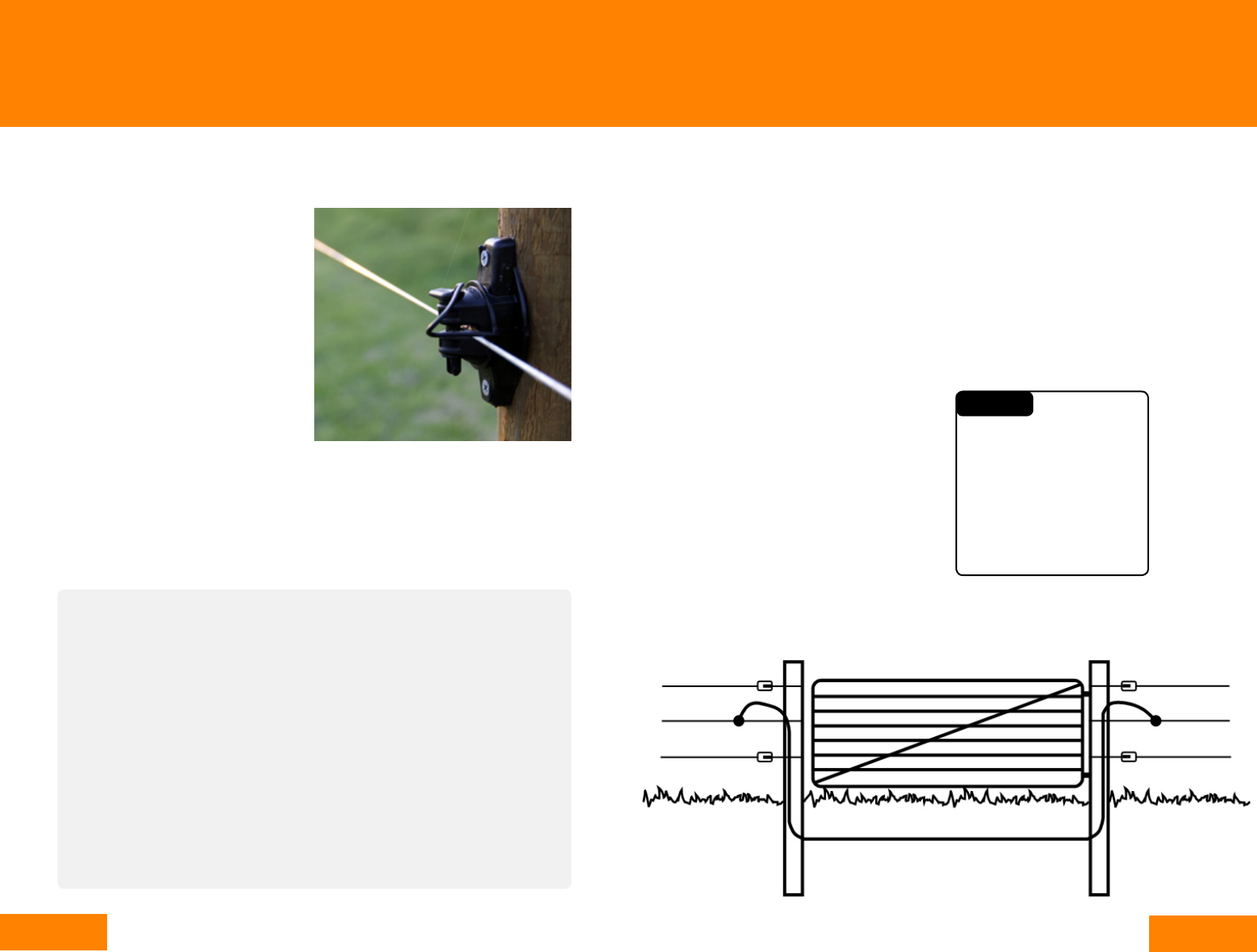

End strain assembly

provides an insulated

attachment between

the wire and the strainer

posts at each end of the

fence.

Hi-Tensile

Wire

Double

insulated cable

In line straining

allows the fence to

be tensioned and

re-tensioned as

required.

Insulators attach the fence wire to the

posts, keeping the wires at the correct

spacing and height.

Offsets specific to Offset Fencing, hold the

electric wire off the existing non-electric fence

wire or posts on a conventional fence line.

Post

Mount

Wire Mount

Fence Wire Types

Braid/Tape

Permanent electric fences for highly effective animal control that lasts a lifetime.

2

Offset Fencing

Extend the life of an existing conventional non-electric fence by retrofitting an electric wire.

Easy to transport, assemble and take down for short-term animal control or rotational grazing.

Reels hold the tape, braid or wire for the portable

fence. You can use just one reel for single line

fences or up to three reels, attached to a reel

stand, for multi-wire fences.

Tapes, Wires and Braids are used on portable fences rather than the

high tensile galvanized wire used on permanent fences. Gallagher

conductors are ideal for portable electric fences as they are light,

visible, easy to wind and durable.

Power Connectors

are leads that connect

a portable fence to an

existing permanent

electric fence.

Portable Posts are lightweight yet sturdy.

Pigtail and Ring Top posts are most popular for

cattle fences and multi-wire treadins are used

for all livestock fences.

Permanent Electric Fencing

1

3

Temporary/Portable Fencing

Fence Wire

Selection of the right fencing systems depends on property size, fencing usage and

animal type. Use this electric fence guide to help you configure your fence based on your

usage and the animal(s) you will be fencing.

Fence Construction

Lightning Diverters

Lightning will likely damage your

Energizer if it strikes your electric fence.

Gallagher Energizers have internal

lightning diverters that give partial

protection against small strikes.

Since lightning always finds the easiest

way to ground, installing a Lightning

Diverter will give added protection by

providing a path for any lightning that

strikes the fence to be diverted to the

ground.

Otherwise disconnect the Energizer

from the fence and power supply during

lightning storms.

Leadout

Leadout describes the cable and wire

that carries the power from the Energizer

to the middle of your fence system. It can

be either run overhead or underground.

Insulated leadout cable should be used

to prevent the leadout from shorting out

on obstructions or the ground and should

be used in buildings, under gateways

and where soil could corrode exposed

galvanized wire.

Undergate cables should not be used for

long leadouts or for long distances

underground, because 16 gauge

galvanized wire will cause resistance to

the flow of current reducing the available

voltage in the fence.

This is not so important on small

properties, but where medium sized

distances of fencing are to be erected

(<10 miles), use 12.5 gauge leadout

cable. On large properties powering large

energizers larger than 20 joules, high

conductive cable should be used.

Never use household electrical cable; it is

made for a maximum of 440 volts and for

inside work only.

Never use copper wire cable because

electrolysis problems occur where it is

joined to galvanized fencing wire.

Keep resistance to a minimum and ensure

maximum power transfer around your

property by choosing the cable with the

lowest ohm’s rating.

Using the diverter does not guarantee

complete protection. In bad lightning

areas, grounding the top fence wire

helps significantly by encouraging

the lightning to get to ground without

passing through the Energizer.

NEVER use household electrical

cable. It is made for low voltage use

only.

NEVER use copper wire/cable

because electrolysis (electrical

corrosion) occurs where it joins

galvanized wire.

CAUTION

21

20

Animals quickly learn to respect

electric fences and keep away

– so the fence looks good for

longer, and your investment is

protected.

Gallagher’s Insulated

Line Post makes fence

construction easy giving a low

maintenance and attractive

fence.

High quality, long lasting

electric fences cost less

than other traditional fencing

options.

High tensile wire systems

create long life, permanent

electric fences. They are

easy to install and provide

highly effective animal

control that lasts.

Permanent fences

use highly conductive,

corrosion resistant fence

wire together with wood,

t-posts, fiberglass and

Gallagher insulated

line posts, couple with

components to keep fences

looking good and working

effectively for a life time.

Cattle

Pigs, Sheep, Goats

Fence Set Ups

23-33’

14”

14”

14”

10”

6”

6”

6”

23-33’

10”

Permanent Fencing

1.

Horses are lively and

at times unpredictable,

so keeping them safely

contained is paramount.

A Gallagher equine fence is

a safe, reliable and highly

visible solution designed to

ensure your horses’ welfare.

Three options are commonly

used for long term equine

electric fencing – a

permanent fence using the

new Equine Fence Wire,

semi-permanent Tape or

Braid fences.

A semi-permanent Tape fence

is highly visible, simple to

construct and will last years,

making this type of fence an

economical and popular choice

for horse owners.

Turbo Braid can be used as a low

tension semi-permanent fence

alternative to Equine Fence Wire.

Braid is designed not to tangle or

overstretch and is easy to install.

Equine Fence Wire is the safest,

most effective electric fence for

your horse. This long life, high

tension fence uses specially

designed wire coating to reduce

risk of injury.

12”

12”

24”

23-33’

Horses

23

22

Permanent Fence Building

Fence Posts

Permanent Fence Building

Fence Tools

While the heart of your electric fence is

your energizer, fence posts are the

backbone of your fence system.

A permanent fence post needs to stand

straight and solid for many years.

Permanent fence line posts typically have

about one third of their length

underground, so add half as much again

to the height of your fence to determine

the post length. End and corner posts

typically have as much in the ground as

above.

There are three basic types of permanent

fence posts: wood, steel, fiberglass.

Wood Posts

Round wood posts provide the basis for a

strong permanent power fence. Gallagher

offers a range of insulators for

attaching electric fence wires to wood

posts, including special equine fencing

products for Equine Fence Wire, braid

and tape. Insulators can be attached

to the post using staples, screws or flat

head nails.

Posts can be installed by digging a hole

and then manually backfilling and

tamping the post tight, or by driving the

post into the ground using a tractor or

trailer mounted post driving machine.

Post spacing depends on the number of

wires, wire type and terrain and can vary

between 15-30’. Post spacing can be

extended if fiberglass, wooden or

insulated wire droppers are installed

between the posts.

Steel Posts

A steel t-post offers a simple line post

alternative to a wood post. Steel posts

have the advantage of being able to be

installed using a sledge hammer or

manual post driver, reducing the need for

expensive post hole diggers or tractor

mounted drivers. They can also be driven

into hard ground more easily. Gallagher

provides t-post insulators that can

snap-on to a steel post and hold a fence

wire.

Additionally, fence toppers are available

for securing a top mounted line post tape

or wire. Post spacing is the same as

wood posts.

Fiberglass Posts

Fiberglass is a quick and easy option for

permanent fences.

Posts are simply driven in the ground

using a post driver. Post clips allow for

wires to be attached.

These amounts may vary depending on

ground contour.

Gallagher Insulated Line Posts

Gallagher’s Insulated Line Posts are a

low cost, low maintenance permanent

post that only requires a hand rammer to

install.

A UV protected polyethylene sheath

protects the fiberglass core from UV

damage and also gives the post the

ability to flex when the fence is impacted,

preventing broken or bent posts, and

minimizing animal injury.

The posts are anchored in the ground

using a multi-flanged foot design and are

perfectly insulated with nylon “snap-on”

clip to hold wire to the post. A tape clip is

also available.

Choosing Permanent Fence Posts

Permanent Fence Tools

Fencing Pliers &

Wire Cutter

G52200

Specifically designed for

cutting, stripping and

bending electric fence wire

with minimum wire damage.

Wire Twisting

Tool

G523004

Ideal for installing clips on

posts and droppers.

Strainer

Handle

G69530

Spring loaded ratchet strainer

handle for quick adjustment

of wire strainers (fits most

varieties of ratchet strainers).

Ratchet Wire

Tightening

Tool

G645004

In line wire tightener

handle with super smooth

ratchet action, to be used

with Gallagher in-line wire

strainers (G64304).

4 Groove Wire

Crimping Tool

A609

20” Long 4-groove, robust

tool for crimping wire joiners

and splicing wire.

Pay Out Spinner

A308

A necessity for building

permanent fence. The

adjustable break keeps wire

from over-spooling and it

attaches to a 2” receiver.

Tie Down &

Handle

G61500 Tie Down

G615014 Handle

Ensures a secure fence tie

down. Tie down and handle

sold separately

Post Driver

G52501

A specially designed driver

for the Insulated Line Post.

Below are some useful tools that will be referred to as

you continue reading.

TERMS

Insulator - a non-

conductive, insulating

device used to secure

the fence wire to the

fence post, providing

reflex insulation

preventing power loss.

Clips - Like an insulator,

clips hold wire on a post.

Clips can be metal or

plastic.

Brace - Fences with

a lot of tension on the

wires are braced at

the corners and ends

to keep the wire from

pulling the corner post

over.

Corner - Where a

straight run of fence

meets another straight

run of fence from a

different direction.

Tie-downs - Are anchors

to hold wire down in

hollows.

Droppers (Stays) -

maintain wire spacing

between posts on

multi-wire

high-tensile electric

fencing. Droppers

reduce the cost of

fencing by allowing

greater spacing

between line posts.

25

24

Permanent Fence Building

Corner Post & Brace Installation

Permanent Fence Building

Corner Post & Brace Installation

Properly designed and installed brace

assemblies, end and corner posts are

keys to building a fence that will last a

lifetime.

Plan the fence line. Avoid rough, stony

or steep areas if possible. Install corners

and ends before adding your line posts.

Set your corner posts in position. A 7’

post, 6” in diameter is usually adequate.

If you are planning to hang a heavy gate

from the post, ensure the post is strong

enough. One of the most common

mistakes made is that installers do not

set their corner, end and brace posts

deep enough.

By far, the most common bracing for end

and corner posts is the “H” or horizontal

brace. The brace has four different parts:

the end or corner post being braced, the

brace post, the horizontal cross brace

that connects the two posts and the

brace wire.

The length of the cross brace should be

2 - 2.5 times the height of the fence.

Tighten the brace with a diagonal wire

that ties the top of the brace post to the

bottom of the end or corner post.

Gallagher recommends at least two

wraps of high-tensile wire.

Installing Corner Posts & Braces

Install a temporary fence for a period of time to see if the

fence design you have chosen works for your needs before

installing a permanent fence.

TIP

Posts:

2 - 6” x 84” min, Full treated Wood

Rail:

Centered at 37” above ground level.

1 - 4” x 120” Wood or 1 - 2” x

120” Thick Wall Pipe

Fittings:

1 - Permanent Wire Tightener

2 - Joint Clamp

2 - Brace Pins, 12”

High Tensile Wire

Although “H” braces afford optimum

strength because they consist of two

posts in the ground, it’s not always

easy to accomplish - especially if you’re

building in rocky soils. When just getting

one post in the ground is a challenge,

construct a “floating” brace.

This brace also consists of four parts:

the post being braced, the brace itself, a

brace wire and a brace pad. The

assembly works by directing the tension

of the fence down the brace.

The most important thing with a

floating brace is the angle of the brace

You will need to create a 30-60-90

triangle with the post, brace and wire.

The brace should be set at 30 degrees

from the ground to the brace and 60

degrees from the post to the brace.

For a brace pad, use either a flat rock or

a patio stone; either will allow the brace

to disperse pressure into the ground. It’s

critical that the post be set deep other-

wise the fence tension will jack the post

right out of the ground.

Gate openings need consideration as

well. Posts may need to be of larger

diameter and set deeper depending on

the length and weight of the gate that will

hang from it.

27

26

Permanent Fence Building

Strainer Installation

To save time and effort, purchase a

Gallagher Insulated Wire Strainer

Kit (G618034). This kit includes

pre-assembled insulated wire

strainer and wire loops for your

end posts, eliminating the need for

special tools or wire tying.

HANDY HINT

Start with a piece of

wire - 3’ in length .

Finish with a tight

tie-off. Wrap the wire 3

times around the strain

wire. Cut or break off

the remaining wire.

Wind the wire once

around the insulator.

Bend the wire so that

the strain is from the

center of the insulator.

Put a 90° bend in the

wire about 6” beyond

the knot to form a

crank handle. Wrap the

wire neatly and tightly

6 times around the

strain wire.

Grasp the wire just

beyond the bend and

crank it parallel to the

fence line (back toward

the post or splice). The

wire will snap right off.

Permanent Fence Building

Line Post Installation

Mark the wire spacings on the corner posts. Tie the strainers no more than

4” away from the post to prevent animals from pushing through the fence

between the post and insulators.

Wire Attachment to End Post Assemblies

Form a knot as shown

and slide it firmly

against the post.

Angle Posts

If you need to install angle posts, a 6”

post is usually sufficient support. If the

angle is less than 90 degrees use inline

insulators outside of the post.

On sharper corners, you may have to

fasten the hot wire on the inside of the

post to prevent it from touching the post.

Install line posts

Use a payout spinner to run out the top

and bottom wires as guides for

positioning line posts. Use 12.5 gauge

high tensile wire for electric fencing

because it retains its tension far longer

than soft wire. It is reasonably easy to

use and conducts enough current for

most situations when connected in

parallel.

Attach the top and bottom wires to

corner insulators and any angle or corner

insulators. Leave the tails long enough so

they can be used for electrical

connections later. Next, tension the

wires just enough to provide a straight

line for positioning the line posts.

Install line posts on rises or hollows first.

As each post is installed, attach the wires

to them to help decide the position of

the next post in the fence line. On sharp

rises, line posts may need a block to

prevent the post from sinking while posts

in hollows may need to be tied down.

Fiberglass posts should only be used in

straight lines.

Install the remaining line posts where

necessary. On flat or level ground use

one post up to every 30’. On hilly or

uneven ground, posts will need to be

closer together to maintain the wire

height.

Run out the remaining wires, tie them off

to the end strain insulators and attach

them to all the posts.

29

28

Feral/Wildlife Fencing put this next to/

near a wildlife setup

i

Permanent Fence Building

Making Wire Connections

Permanent Fence Building

Making Wire Connections

Tension the wires to approximately

200lbs using Permanent Wire Tighteners

and a suitable tensioning handle. If wild

animal pressure is likely, increase the

tension, especially on the bottom wires.

In regions where snow load is a problem

or where wildlife may come into heavy

contact with the fence, install permanent

tension springs to help prevent the wire

overstretching. Place permanent wire

tighteners in the center of the fence so

the wire pulls from both ends.

Tension the wires

Gallagher

Recommends –

re-tightening joint

clamps as part of

a regular spring

fence maintenance

program.

Reef knot

Figure 8 knot

Join wire using a figure eight or reef

knot. These will give better electrical

contact than a double loop join.

TIP

Electrical connections

Connect all hot wires in parallel at both ends of the fence. This will ensure maximum

conductivity. For a three wire fence, bring the tails, previously left long from the top

and third wires to the second wire and connect firmly with a Joint Clamp.

Make sure it’s tight. Wrap the excess wire around this second wire and break it off for a

smooth finish. Bring the tail from the second fence wire to a Gallagher Cut Out Switch

and where necessary break it off. This wiring configuration minimizes the number of

joint clamps and creates a clean look.

Joint clamps

All other permanent connections should

be clamped using Joint Clamps to ensure

tight wire connections. Multiple joint

clamp options are available.

Cut out switches

Cut out switches are handy for

isolating different sections of fence. This

is useful when you are looking for faults

or carrying out maintenance. Place cut

out switches at gateway or junctions

where a single or multiple fence line can

be turned off.

Connect the undergate cable to one

switch terminal and the tail of the second

line wire to the other terminal.

31

30

i

Permanent Fence Building

Insulator Selection

Permanent Fence Building

Gate Installation

Gallagher’s heavy duty plastic

insulators are made from the highest

quality polymers infused with UV

stabilizer for sun resistance, toughness

and durability. Porcelain insulators are

fire-resistant and ideal for high fire risk

areas.

The type of insulators you require will

depend on the type of post and the type

of wire that you have selected for your

electric fence.

To determine the number of insulators

you require: calculate the number of

fence posts x the number of strands =

number of insulators needed.

For corners and ends, use insulators

made specifically to handle the extra

wire strain. To determine the number of

corner/end post insulators you require:

calculate the number of corner/end

posts x the number of wire strands =

number of corner/end post insulators

needed.

Choosing the right insulator for your fence

Where possible, position gateways on

flat, firm areas, away from steep banks

where erosion could occur. Carry the

power (and ground return if you have

a ground wire return system) across

the gateways preferably underground

using double insulated cable in a pipe

for protection and simple maintenance.

Seal ends or turn ends of pipe down to

keep out moisture. Bury the cable/pipe

at least 12” deep and cover with soil that

is free of rocks and debris. Connect the

cable ends to the fence using join clamps

or through a Cut out Switch.

Electrified Gates

Electric gates are low cost, effective and

extremely easy to install. Choose from

high visibility electrified spring gates, ,

bungy gates and single or multi-strand

tape gates.

Electric gates should be wired so they

are dead when they are unhooked.

Tape gates provide the most visible gate

solution. Choose spring or bungy gates

where the gate needs to be stretched

across a road to divert animals into the

paddock. Gallagher Electric Gate Kits

come pre-assembled ready to install and

include an insulated gate handle.

Gates and gateways

Gallagher offers a range of insulators

for attaching electric fence wires to

your chosen post.

Wood Post Insulators

The Claw insulator provides a strong

permanent attachment system with

large shield. Alternatively Pinlock

insulator products enable the wire

to be temporarily removed from

the fence while under tension. For

example when wires need to be

lowered for temporary vehicle access.

Insulators are also available for equine

fencing products including for tape

and Equine Fence Wire. These are

all attached to the post using staples,

screws or flat head nails.

Steel Post Insulators

Gallagher manufactures quality double

pinlock insulators for attaching elec-

tric wires to steel t-posts and y-posts

as well as a topper cap for securing a

top mounted tape or wire.

Fiberglass Clips

Attach wires to Fiberglass posts using

metal clips.

Insulated Line Post Clips

Attach wires or tape to Gallagher

Insulated Line Posts using specifically

designed insulator clips.

Do not rely on electric

gates to get power across

gateways because when

the gates are open power is

lost to the fence. Also the

conductor in an electric gate

is not designed to carry high

currents so power will drop

even when closed.

CAUTION

Steel Gate example

33

32

i

Offset Fencing

Selecting Your Offsets

Offset electric fencing is an economical and easy to install option if you have an existing

or new non-electric fence that you want to protect.

Offset brackets are fitted to

a conventional fence with an

electrified wire (or wires) on one or

both sides of the fence. The wire

discourages animals from rubbing

or pushing against the fence,

thereby extending its life.

A variety of offset brackets are

available to attach to wood post or

t-post fences, or to mount directly

onto the wires of an existing non-

electric fence (barbed wire, chain

link, etc.).

Once you’ve chosen your

products, see below for the

recommended offset electric

fence set up for cattle, sheep,

pigs, goats and horses.

2.

Offset wire mounts provide

added protection for traditional

fences. This protects your fence

investment and extends the life

of the fence.

A side mount pigtail offset

is a popular option for wood

post fences. Provides

complete freedom for the

offset wire placement.

Offsets come in many options

including Porcelain. Porcelain

insulators will not break down

due to sun damage and are

resistant to fire.

Offset Fencing

Cattle

Pigs, Sheep, Goats Horses

Fence Set Up

23-46’

28-35”

20”

40”

23-46’

23-46’

Choosing offset brackets

Conventional fences can be made to last

for many more years by attaching offset

insulators with an electrified wire on one

or both sides of the fence.

Gallagher recommends attaching a single

offset wire at two thirds the height of

the animal to be controlled. If sheep and

cattle are in the same area it is better to

use two offset wires (one for sheep, one

for cows). However a single wire three

quarters the height of the sheep will still

protect the fence from both animal types.

If the old fence is tangled or has broken

wires, it will need to be repaired.

Otherwise you will run the risk of loose

non-electric wires causing accidental

shorting on the electric offset wire.

Change the worst wires and tighten the

others where possible.

Wire mount offsets twists onto your

conventional fence wire and provides

maximum flexibility when something

impacts against the fence

Chain link offsets, like wire mount

offsets, are made from galvanized high

tensile spring wire and are twisted onto

existing chain link wires.

Wood post offsets are driven into the

side or top of wood posts and then

stapled in place. The are ideal for horse

fencing due to their high visibility and

ability to mount to post and rail fencing

T-post offsets are a low cost, simple to

install offset option. They extend 5” and

their extra locking tab will fit all t-posts.

Mistakes made with an offset fence

The most common error is the use of soft

wire for the fence wire and for the offset

bracket. High tensile wire should always

be used for the fence wire, and only

spring steel wire for the offset brackets.

The bracket must be able to spring back

in place after impact or it will become

entangled with the wire of the old fence

and short out.

The second most common mistake is

the use of brackets that are too short

allowing the hot wire to remain too close

to the fence it’s attached to. Brackets

should hold the hot wire 5-12” from the

old fence. Some brackets on the market

are 4” long or less.

The placement/height of the hot wire is

also very important. It should be attached

at two-thirds the height of the animal to

be controlled. Two offset wires, can and

often are placed on the same fence. On

one side a wire is placed at 30” to contain

cattle, on the other side a wire is placed

at 8” to repel predators.

As simple as it is, offset fencing still must

be viewed as a system. One short cut, or

one substandard component can destroy

the effectiveness of the fence.

35

34

i

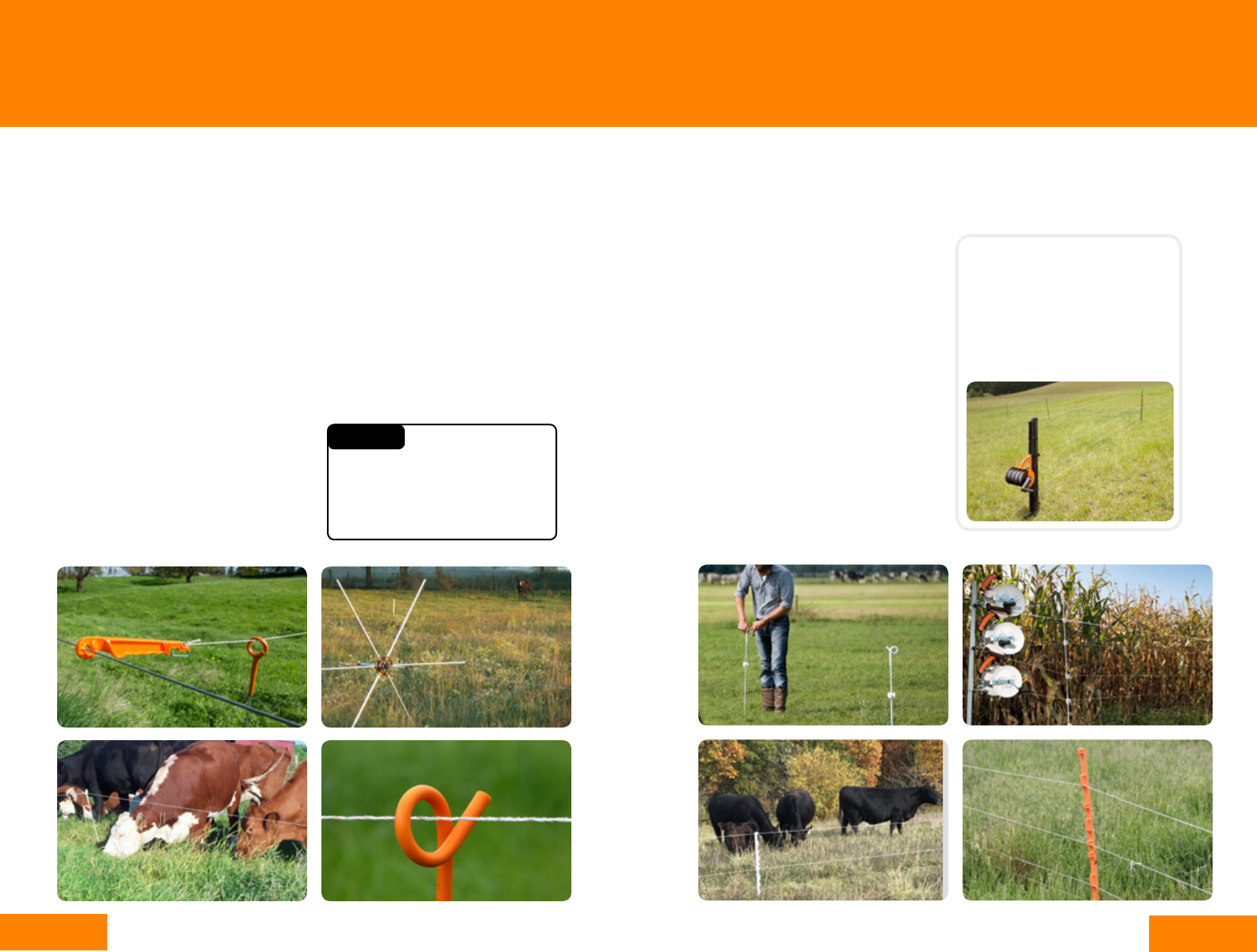

Temporary & Portable Fencing

Wire Selection

23-33’

28-35”

A temporary/portable electric

fence can be powered by any

Gallagher Solar or Battery

Energizer or can be simply

connected to a permanent

electric fence supplied by a

110v powered Energizer.

As portable fencing is so easy to

move and set up it’s a versatile

solution for fencing any type of

animal, even on the most remote

area of your property.

See below for the basics you’ll

need for portable fencing and

the recommended fence set up

for cattle, sheep, pigs, goats

and horses.

The Smart Fence 2, is an all-in-

one portable fence. This instant

fence system combines posts,

reels and wire in one easily

transportable package.

Ring Top Posts are a popular

choice for cattle farmers.

A single electrified wire is

sufficient to contain even the

most temperamental animals.

The multiple lugs on Multi-wire

Treadins allow attachment of

a number of wires at different

heights to accommodate a

variety of animal types.

*Note: Wire spacing will differ depending on the type of post used.

Reels hold the tape, braid or wire for the portable

fence. You can use just one reel for single line

fences or up to three reels, attached to a reel stand,

for multi-wire fences.

Tapes, Wires and Braids are used on portable fences rather than the

galvanized wire used on permanent fences. Gallagher conductors are

ideal for portable electric fences as they are light, visible and easy to wind.

Highly conductive Turbo products are ideal for fences longer than 660’

Power Connectors

are leads that connect

a portable fence to an

existing permanent

electric fence.

Posts are lightweight yet sturdy. Pigtail and Ring

Top posts are most popular for cattle fences.

Multi-wire treadins are used for all other animals.

Fence Set Up

Pigs, Sheep, Goats, Calves*

Cattle (no calves)

Horses

23-33’

8”

10”

8”

23-33’

24”

24”

Temporary & Portable Fencing

3.

* recommended for horses

Turbo Braid - 3/16”

G62174 656’, White

G62176 1,312’, White

• 9 Mixed metal strands

• Most user-friendly for horse

fencing - visible and safe

• Best suited for any distance temp

or permanent fence

8kV 7.5kV 7.1kV 125 •

Turbo Braid - 7/64”

G62148 1,312’,

White /Blue

• 9 Mixed metal strands

• Superior heavy duty strength

8kV 7.5kV 7.1kV 125 •

Turbo Wire

G62054 656’

G620564 1,312’

G62089 2,624’

• 9 Mixed metals

• Best suited to distances more

than 1/4 mile, where extreme

power is required

• 40 times more conductive than

standard Poly Wire

8kV 7.5kV 7.1kV 130 •

Poly Wire

G62004 656’

G620300 1,640’

• 6 Stainless steel strands

• Best suited for distances under

1/4 mile

5kV 2kV 1kV 6,000

/2” Turbo Tape

G62354 656’

G62356 1,312’

• Mixed metals 30x’s more

conductive

• Best suited for distances greater

than 1/4 mile

7.8kV 7.1kV 6.4kV 250 •

/2” Poly Tape

G62304 656’

• 6 Stainless steel strands for good

conductivity

4.3kV 1.5kV 0.8kV 8,500

/2” Turbo Tape *

G624544 656’

• 15 mixed strands for ultra high

conductivity

• Reinforced edges for longer

life & open weave for low wind

resistance

7.8kV 7.1kV 6.4kV 250 •

/2” Poly Tape *

G624044 656’

• 15 Stainless steel strands

• Ideal for portable electric fences

4.3kV 1.5kV 0.8kV 8,500

Braid, Wire, Rope

1/2” Tape1 1/2” Tape

Conductor

Selection Chart

MIXED

METALS*

’

FENCE

RESISTANCE

(Ohms/miles)

1.640’

FENCE

3,280’

FENCE

FENCE VOLTAGE

Wire

Preferable where wind

and adverse weather

conditions exist.

Braid

Braided construction is

designed not to tangle or

overstretch adding durability.

Tape

Generally used where

visibility is most

important.

37

36

Feral/Wildlife Fencing put this next to/

near a wildlife setup

i

Temporary & Portable Fencing

Wire Selection

Temporary & Portable Fencing

Difference between Turbo and Poly Products

There are a number of different types of

portable electric fence wires, tapes and

braids - frequently called “conductors”.

Knowing which one to choose can be a

bit tricky - especially for those new to

electric fencing.

The most common portable/temporary

fence “conductor” is what is called Poly

Wire. Poly Wire is made of plastic strands

and embedded thin metal wires used

to carry electrical current from a Fence

Charger/Energizer. The individual strands

of plastic and wire are typically twisted

tightly together to form a single wire.

A second option is Poly Tape. Poly Tape

threads individual strands of plastic and

wire together creating what appears to

be a highly visible ribbon. Tape while

prone to wind and ice damage, is the

most visible “conductor” and is best used

in situations where maximum visibility

is needed. Poly Tape comes in different

widths, but the most common are 1/2”

and 1 1/2”.

A third option is Poly Braid. Poly Braid is

thicker and more visible than Poly Wire,

and is less likely to be damaged by the

wind and ice than Poly Tape.

Poly Braid consists of individual strands

of plastic and wire that are braided

together to form a tight weave making it

more durable, and less prone to tangles

and overstretching. Poly Braid comes in

a number of different diameters (thick-

ness).

Understanding Wire

Turbo products are always

the best choice for distances

beyond 1/8 mile where

dependable power is

required.

Electrical Connections

It is important to have good

conductivity through the connection

when you join wire or tape.

To do this, separate the metal strands

by melting a strip of plastic threads

with a match or lighter approximately

2” from the ends of each length. Pull

the end off the plastic being careful

not to break the steel wires. Tie both

ends of the wire/tape together and

then twist the steel wires together.

To join 1 ½” Tape use a Tape Joiner.

These also give good electrical

contact.

Turbo products come in the same wire, tape and

braided construction previously described for Poly

- with one major difference. Turbo products have

9 strands of conductive metals including copper

which make them up to 48X’s more conductive than

Poly products which only have 6 strands of stainless

steel. This means with Turbo, your voltage will stay

strong and carry a “shock” further down your fence

line than Poly products. Long temporary fences (over

1/8 mile) should always be constructed from Turbo

products to ensure maximum livestock control.

So what is Turbo Wire

and how is it different

from Poly Wire?

Some metals conduct power better than others.

Metals that are good conductors are said to have

low resistance and metals which are not good con-

ductors have high resistance. Copper happens to be

a very low resistance conductor which enables Turbo

products to carry power further down the fence line

than Poly products. The copper wires in Gallagher’s

Turbo products are tin coated. This is why if you

pull the plastic and metal strands apart, you will not

see copper colored wires. The advantages of tinned

copper over a non-tinned copper wire is greater

longevity. Copper coated in tin is less susceptible to

corrosion and even more conductive!

Why is copper so

important?

What this means is that if you built two different

fences .6 miles long and one was a single strand of

Poly Wire and the other was a single strand of Turbo

Wire - both fences would read 8,000 volts at the

start; however, at the end of the fence you would

only read 600 volts on the Poly Wire fence while the

Turbo Wire fence would read 6,300 volts.

The resistance of a “conductor” (wire/tape/braid) is

measured in Ohms. The lower the resistance, the

more conductive the wire/tape/braid will be. As you

can see from the values below, Turbo Braid is 48

times more conductive than Poly Wire.

Turbo Braid - 125 Ohms/mile

Poly Wire - 6000 Ohms/mile

What does it mean

that “Turbo is 48X’s

more conductive than

Poly”?

39

38

ELECTRIC FENCE SYSTEM D Portable/Temporary Fencing

i

Temporary & Portable Fencing

Fence Posts

Temporary & Portable Fencing

Reel and Gate Selection

Reels

Reels are an absolutely essential

component of your portable electric

fencing equipment.

They are designed to hold your wire, braid

or tape and make it extremely quick and

easy to roll up your temporary

cross-fences.

Gallagher’s geared reel comes with a

locking device allowing for secure

attachment to an ATV or fence wire.

Geared reels also have a 3:1 ratio which

means for each turn of the handle, the

bobbin spins three times allowing you to

wind your wire three times faster with

each turn of the handle.

Geared reels are designed to hook the

spool in place so it does not unravel.

The hook allows you to hang the reel off

of your permanent high-tensile electric

fence.

An alligator clamp (also called a lead con-

nector) is used to create a good electrical

connection between the portable electric

fence and your permanent electric fence.

Use an insulated handle on the far end

of your portable electric fence so the

fence is only powered from one side (at

the geared reel). This ensures that the

portable fence loses power once you

disconnect the alligator clamps and

geared reel so you can roll up the wire

without getting shocked.

When rewinding long lengths of poly/

turbo wire, braid and tape, the geared

reel is a worthwhile, time-saving

investment.

Portable Fence Posts

When installing a temporary fence, there

are many durable, portable fence post

options available.

Many portable fence posts come with a

step-in feature. At the base of a step-in

post, there is a footplate that allows you

to push the post into the ground with your

foot. This is a convenient feature so you

won’t need to drop your bundle of posts in

order to pound them into the ground.

Other factors to consider are visibility,

durability and the ability to add

multiple wires for the animal needing to

be fenced. Weather also influences

selection as posts are much more

difficult to insert into frozen ground.

Plastic Posts

Plastic step-in posts with built-in foot

plates are convenient because they have

pre-molded loops for multiple wires at

various heights. Plastic posts are made

from a heavy duty, UV-resistant polymer

plastic and have a steel foot spike.

Metal Posts

Metal step-in pigtail posts are also

available. These posts get their name

from the curl loop that holds the wire and

looks similar to a pig’s tail.

Gallagher’s Ring Top Posts have a very

high strength plastic head and foot

coming in both a standard and heavy duty

model.

Gallagher’s Ring Top Post while similar to

the Pigtail, has a ring shaped nylon head

that prevents wear and reduces tangles.

The post’s glass reinforced nylon

footplate is strong and will not bend.

A Multi-Wire Ring Top Post is also

available. This product is suitable for

containing most animals including cattle,

sheep and goats.

Fiberglass Posts

Fiberglass rods are better for

situations when the fence is not going to

be moved as often because these have to

be pounded into the ground. These rods

require the use of wire clips or plastic

insulators that slide on the rod to hold the

wire in place.

Rolling Posts

The Tumblewheel enables you to quickly

and easily roll a fence line to a new

position. The Tumblewheel’s unique

center hub maintains power while the

fence is being moved. It can be used on

flat very hard and frozen ground. The legs

remain live except for two legs that are

on the ground.

Where several breaks are needed in one

paddock, Tumblewheels are ideal for

quick and efficient rationing of grass. We

recommend spacing at every 66’.

This fence consists of a number of

electrified ‘wheels’ spaced across the

pasture. The wheels are held upright with

the tension of the single line fence which

passes through the center.

When one or both ends of the fence is

moved, the wheels roll along. When you

stop, the fence stops.

41

40

Multi-wire Fence

1. Attach the required reels to a reel

stand & chain the reel stand to an

anchor point.

2. Hook the insulated handles through

the head/lug of the first post to

prevent them becoming twisted.

3. Follow steps 2-6 as per the single

wire fence instructions only this time

with multiple lines together not one

single one.

Note – place posts every 33-40’ and

use a multi-reel lead connector if

using a battery Energizer.

Portable Fence Construction

Reels holding wire/tape can be used individually for single line fences or for up to

three lines using three reels attached to a reel stand.

Single Wire Fence:

1. Hook the reel to the anchor point

(e.g.: permanent fence/reel stand) and

disengage the ratchet.

2. Carrying the insulated handle and

sufficient portable posts, walk along

the proposed line allowing the reel to

unwind and connect to the other end.

3. Walk back to the reel, placing a post

every 50’ (or closer on uneven ground)

and locate the wire/tape in the post.

4. At the end of the fence, engage the

ratchet and tension the wire.

5. Connect to power – either connect to

the permanent fence by connecting

leadset to both powered permanent

fence line and the portable wire or

using a solar or battery Energizer.

6. When you remove the fence, do the

same process in reverse.

ELECTRIC FENCE SYSTEM D Portable/Temporary Fencing

i

Temporary & Portable Fencing

Single Wire Construction

Temporary & Portable Fencing

Multi-Wire Construction

All in one multi-wire portable

fence system

A quicker and easier all in

one instant fence system, the

Smart Fence System includes

4 wires, 10 posts, 328’ length.

Energizer is sold separately.

Do not wind the conductor through

the posts as the abrasion will

damage the post.

CAUTION

43

42

ELECTRIC FENCE SYSTEM D Portable/Temporary Fencing

i

Fault Finding

Searching for a fault

A short is a fault somewhere on the

fence that has caused it to lose power.

The most common types are

vegetation overgrowth, loose wires

and broken insulators.

Gallagher has some great tools for testing

and finding these quickly and easily.

• Fault Finder – shows voltage, current and

direction of fault (an i Series Remote also

has this function)

• Fence Volt Meter - a digital read out of

the voltage at that point on the fence

• Live Fence Indicator – sits on your fence

line and flashes with each pulse over 2kV

so you can see from a distance

To trace a fault using a volt meter travel

along the fence line and check the voltage

about every 330’ . If the short is serious,

the voltage will continue to fall until the

fault is reached. If the fault is passed the

voltage will remain fairly constant. You

should then backtrack to find it. At fence

junctions isolate different fences with a

Cut Out Switch to try to isolate the fault.

Using a Fault Finder

1. Place the Fault Finder or remote on the

fence with the wire in the measurement

slot and making good contact with the

contact plate.

2. The arrow on the LCD display will

indicate which direction the current is

flowing. The amount of current (Amps)

and voltage (kV) will show on the display.

The higher the current, the bigger the

fault.

Travel along the fence line checking the

readings every 330’ or so. If the current

reading drops significantly the fault is

back towards your previous reading. The

process is similar to finding water leaks,

where the Fault Finder is reporting the

amount and direction of the flow.

Multi Wire Fences

When the fence has multiple live wires,

the current should be measured on

each wire. Assuming the live wires are

connected in parallel at each end of the

fence the total current flow is the sum of

the current on each wire.

When one wire has a much higher current

reading than the others, either this wire

has the fault on it or the wires have not

been connected in parallel at each end

of the fence line and this wire only is

supplying power to the next section of

fence.

Induction

Induction is the transfer of voltage

from a live wire to a neutral wire by

electromagnetic rather than direct physical

contact.

If you are getting a small shock from

“non-live” wires or steel gates, particular

in dry weather, this is likely to be caused

by induction. Neutral wires (neither live

nor ground) can be charged from live wires

(usually leadout or offset wires), running in

parallel. It is not a short and will not reduce

fence voltage.

To remove the problem, ground out the

offending wires by pushing a heavy gauge

galvanized wire as far as possible into the

ground next to the strain post and staple

it across the offending wires. This will

not reduce the voltage on the insulated

powered wires.

If you find there is not enough power on your fence follow the chart below to find the

most common causes.

Fault Finding

Faulty ground system

Install the grounding

system.

45

44

General safety

Don’t touch fences with your head or mouth.

People with pacemakers or other heart

problems also should consult their doctors

before working with or near electric fences.

Always use precautions.

Energizer installation

Only connect one energizer to a fence.

Can electric fences cause fires?

There is a misconception that dry

vegetation touching an electric fence can

cause fires – this is extremely unlikely. In

order to create a short, vegetation needs

to be damp or green so therefore the

vegetation will not ignite. Once vegetation

dries out it becomes non-conductive

meaning any short created disappears.

The only conceivable but still very unlikely

scenario where an electric fence could

start a fire is when a wire shorts to an

grounded metal object, such as a steel post

or wire where insulators have broken, in the

presence of abundant dry vegetation. This

scenario is very unlikely to occur in practice,

and even less so on a well-maintained

fence.

Producers with fences on steel posts or

those using grounded wires in the fence

are advised to ensure the live wires are

well insulated and the fence is clear of

vegetation. If these factors are of concern

then on days of severe or above fire risk,

consider turning the energizer off.

Ground rods for energizers should be at

least 65’ from utility grounding fields.

Electric fence construction

Avoid running fences parallel to power lines,

and try to install fences so that they cross

power lines at right angles. If you can’t avoid

parallel electric fences and power lines,

offset the fences at least 30 feet from the

power lines, and make sure the top fence

wires are no more than six feet high.

Do not attach fence wires to utility poles.

Electric fences bordering public

thoroughfares are required to have a

warning sign at least every 295’ feet where

the public has access to electric fences,

such as along roads.

Check with your local authority for

specific regulations.

Landowners are responsible for preventing

audible interference with telephone lines.

Therefore, try to avoid installing electric

fences under telephone wires, and minimize

the distance that electric fence wires run

parallel to underground telephone cables.

This particularly applies if the electric fence

wire is carrying high current, such as a

leadout wire to a large fencing system. (See

‘Telephone Interference’ pg 46)

ELECTRIC FENCE SYSTEM D Portable/Temporary Fencing

i

Safety

Safety

Never use barbed wire for electric fence wire

because people or animals could more easily

become entangled in it.

Radio Interference

Keep electric fences as far away from radio

antennas as possible. Gallagher energizers

comply with usual Telecom and International

standards and safety regulations. However,

problems can arise for a number of reasons

and can be difficult to eliminate in areas with

poor radio reception.

To avoid radio interference:

• The energizer ground must be highly

conductive

• The energizer must be well away from

any electrical power supply

• The energizer should be well away from

any water pipes

Do not allow an energizer ground wire to

touch a building which can act as a broadcast

aerial. Use proper leadout cable to insulate

the ground wire. Ground the offending radio

and improve its aerial. Try to keep both as far

away from the energizer and fence lines as

possible.

Here are some safety considerations to follow when installing electric fencing:

All types of wire

may break and

recoil when

stretched. Always

use hand and eye

protection when

handling hi-tensile

wire.

47

46

Are all sections of the fence and the

connecting leads over 10 metres away

from the telephone cables or lines?

Is the ground system inadequate or

within 10 metres of a power or

telecommunications ground or

building structure with mains power?

Y - Improve or relocate the ground.

connecting leads within 10 metres of the

Telephone Interference

Use the following chart flow to determine if your fence is likely to be causing interference

on telephone lines.

i

Safety

Safety

1. Draw a plan of the property approximately to scale showing:

• All electrified wires.

• The connecting leads between Energizer, fence and ground rods.